If you want a lower Low and your crankset has an intermediate bolt circle, which accepts a 32-, 34-, or 36-tooth minimum chainwheel, plan on a double with wide-range crossover gearing using the smallest available inner chainwheel. Don’t even think about converting to a triple. A 34-tooth chainwheel combined with a 34-tooth freewheel cog gives you a 27-inch Low. When your Low is limited by a 32-, 34-, or 36-tooth inner chainwheel the complication of a triple just isn’t worth it.

Earlier, in section 3, I presented you with the theoretical side of the gearing story and gave you two sets of teeth numbers: one for chainwheels and the other for freewheel sprockets. In this section, 1 will tell you how to convert the hypothetical chainwheel numbers into actual chainwheels and cranksets. ( Section 6 will explain how to convert the freewheel numbers into sprockets and freewheels.)

The crankset is the most expensive component on your bicycle. The bicycle designer selected the crankset to match the bicycle’s intended price range and its intended use. Expensive racing cranksets go on expensive racing bicycles. Inexpensive sport touring cranksets go on inexpensive sport touring bicycles. The importers, the mail-order houses, and the bike shops tend to carry expensive, top-of-the-line cranksets. Lower-priced versions are sold to the OEM bicycle makers. For these reasons, it may make more sense to replace an inexpensive bicycle rather than to replace the crankset.

Chainwheels are expensive too. They run from $10 to $40 each, while freewheel sprockets cost only $3 to $10 each. Plan your gearing modification to fit into your total upgrading budget.

________ Economic Choices __________

You have four options to choose from when upgrading your gearing:

• No crankset changes; freewheel changes only ($20 to $40).

• New inner chainwheel and freewheel changes ($30 to $50).

• Two new chainwheels and freewheel changes ($40 to $60).

• New crankset and freewheel changes ($150 to $250).

Each option will cost $30 to $70 more if you also replace the derailleur(s). Notice the big price jump when you replace the entire crankset. The usual reason for replacing cranksets is to get a lower Low by converting to a triple. Just make sure that you’re going to be happy with the finished bicycle after you’ve spent all that money.

_____ Crankset Terminology ______

Terminology time. The bottom bracket is really the shell that ties the seat tube, down tube, and chainstays together. The bottom bracket set is everything that fits into the bottom bracket: that is the spindle, fixed cup, adjustable cup, lockring, and bearings. However, many people, including yours truly, often call the bottom bracket set just “bottom bracket” to keep you alert. The crankset is the whole package: bottom bracket set, left- and right-hand cranks, chain wheels, chainwheel bolts, and dust caps. The crankset includes the bottom bracket set except when you see a low-ball price with the cryptic note “w/o bb.”

Spider describes the arms on the right hand crank that hold the chainwheels. The words chainwheel and chainring are used interchangeably. In the prehistoric days of cottered “five-pin” cranks, chainwheels went on the outside and were bolted to the crank with five bolts called pins. Chainrings went on the inside and were bolted to the chainwheel with six bolts. Don’t ask me why they’re called “pins” and “bolts.” It was probably a poor translation from French. The venerable TA Cyclotourist crankset still uses this arrangement.

____ Crankset Features _____

Although crankset prices vary widely, there’s surprisingly little performance difference between a $50 melt-forged Sakae FXC and a $500 Campagnolo C-Record. (“Melt-forging” is the name of an improved aluminum casting method.) I judge cranksets by the following features, in order of importance.

__ Bolt Circle Diameter--Minimum Inner Chainwheel __

The essential difference between racing and touring cranksets lies in the size of the bolt circle diameter and the corresponding size limitations on the inner chainwheel. A racing crankset with a large-diameter bolt circle is a bit more rigid, but the smallest inner chainwheel it can accept has either 39 or 42 teeth. A loaded touring crankset is less rigid, but its small-diameter bolt circle accepts inner chainwheels with 24, 26, or 28 teeth.

There’s also a group of intermediate sport touring cranksets whose bolt circles take 32-, 34-, or 36-tooth minimum chainwheels. They rarely make sense if you’re buying a new crankset. If you want a 32-, 34-, or 36-tooth inner chainwheel, buy a loaded touring crankset with a larger than minimum inner chainwheel. You can change your mind later.

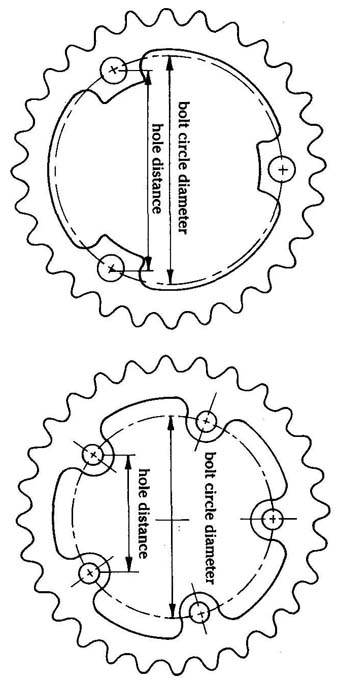

There are more than 40 different bolt circles made. If your crankset uses 1 of the 6 standard bolt circles, you have multiple sources of replacement chainwheels. If your crankset uses 1 of the many bastard bolt circles, you’ll have go to the importer and beg. TABLE 1 lists 20 fairly common bolt circles. You can find chainwheels for these bolt circles if you search hard enough. Measure the diameter of your bolt circle (or the distance between the bolt holes) and TABLE 1 will tell you what chainwheels are available and where to look for them. FIG. 1 shows how to measure bolt circles. I’ll have more to say about bolt circle standardization further on.

The rigidity aspect of crankarm design is exaggerated. If your chainwheel rubs against the front derailleur when you stomp on the pedals, it’s probably your frame that’s deflecting, not the crankset. Bicycling magazine tested the rigidity of cranksets in the October 1984 issue. The basic conclusions were that the differences were small and not significant in pedaling efficiency. I show the results of their tests in the rigidity column of TABLE 2.

Avocet/Ofmega and Sugino machine a notch at the base of the crankarms to provide chain clearance. This lets them install 41- and 38-tooth chainwheels on 42- and 39-tooth bolt circles. If your crank doesn’t have the notched spider, you may have problems with the 41- or 38-tooth chainwheels.

TABLE 1: Crankset Bolt Circles

FIG. 1 Measuring bolt circles.

===

TABLE 2: Cranksets

1. The racing crankset prices are for doubles. The loaded touring crankset prices are for triples. The prices include the bottom bracket set. Where there are two bottom bracket sets available, it covers the lower-priced one.

2. The weights shown are for a racing crankset with 52/42 chainwheels and a touring triple crankset with 50/45 outer chainwheels and the smallest inner chainwheel. Both weights are for cranksets with 170mm cranks and they include the bottom bracket set.

3. 57—39 means that chainwheels are available in I-tooth steps from 57 to 39 teeth. 44-34 even” means that only chainwheels with even-numbered teeth between 44 and 34 are available.

4. Inclusive numbers indicate the availability of lengths in increments of 2.5mm. Thus, 165—180 means the following lengths are available 165, 167.5, 170, 172.5, 175, 177.5, and 180.

===

________ Crankarm Length ________

Before 1980, all stock bicycles came with 170mm cranks. Then Miyata began to offer crankarms and stems to match the frame size. This was a nifty sales feature and soon the rest of the industry caught up. In section 2, table 2, I correlated various crank lengths with leg lengths. The crank lengths listed there were chosen under the assumption that you pedal at a normal cadence. However, if you’re a lightweight spinner, you may want to choose a shorter crank. On the other hand, if you’re a heavyweight pedal masher, you may want to pick a longer crank. (Longer and shorter means, say, plus or minus 5mm.)

I use cranks 5mm longer than table 2-2 recommends. In theory, the bottom bracket should be raised to match the longer crank. In practice, bottom bracket heights are designed to allow racers to pedal around corners. Most of us don’t fit that category and we can use lower bottom brackets or longer cranks and never drag a pedal. If you buy a new crankset, by all means buy the right crank length.

Crankset Design:

Twenty years ago, there was a plethora of crankset designs. There were one-piece “ Ashtabula” cranksets, steel-cottered cranksets, and alloy cotterless cranksets. The outer chainwheel was bolted or swaged onto the right-hand crank or the crank had a three- or five-arm spider to hold the chainwheels. The best-quality cranksets were forged from aluminum alloy with a five-arm spider to hold the alloy chainwheels. They had “cotterless” cranks that bolted onto square tapers at the end of the spindles. Best quality was usually spelled Campagnolo Record.

In the late 1960s, Sugino introduced the inexpensive Maxy crankset with an alloy three-arm spider swaged onto an alloy cotterless crank. The swaged Maxy looked a bit like a top-quality crankset. It sold for the price of an inexpensive steel-cottered crankset and it weighed two pounds less. Soon every bicycle selling for more than $100 sported cotterless alloy cranksets. Three-arm swaged Maxys begat five-arm swaged Super Maxys that begat forged five-arm Mighty Tours. Sakae, Shimano, Stronglight, SunTour, and Takagi were soon making Maxy-style cranksets. They’ve become the standard for standard- quality bicycles and all other designs are passé.

At the 1982 New York Bike Show, Campagnolo showed a prototype of atop- of-the-line crankset, which was to become the C-Record. I had to elbow the Japanese photographers out of the way to look at it. Instead of the right-hand crank sitting on top of the spider, it was nearly flush with the spider and the spider arms went back to the outer chainwheel. The crank came out at a slight angle and its cross section was rounded and oblong instead of square. The design was more rigid and it offered more ankle clearance than earlier designs. It used a shorter, stiffer spindle and it looked simply elegant. The Swiss company, Edco, showed a similar design at the same show. It took Campagnolo three years to get the C-Record to market, but the clever Japanese were much faster. Virtually all of today’s cranksets show the influence of Campagnolo and Edco.

Bottom Bracket Spindles:

Spindles come in three basic lengths: for single, for double, and for triple cranksets. Double and triple spindles also often come in both long and short lengths. The spindle length is designed to put the chainline in the middle of the freewheel. On a double, this means that a line drawn from the midpoint of the two chainwheels should fall on the middle cog of a freewheel. However, I don’t think that this is the right way to set up a triple, because you never use the little chainwheel with the small sprockets. It’s better to set the chainline of a triple so that the inner chainwheel just barely clears the chainstay.

You can often use a double spindle with a triple crankset. A 1/16-inch-thick spacer under the right-hand cup will sometimes provide the necessary clearance. Usually there will be enough threads to secure the locknut on the left-hand cup. The newest Shimano and Specialized triple cranksets are designed to use double spindles.

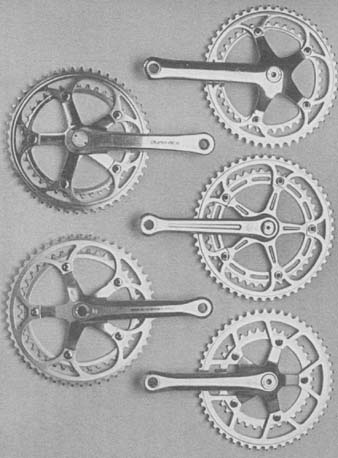

PHOTO 1 Racing cranksets: top left to right, Campagnolo C-Record, Campagnolo

Super Record, and Campagnolo Nuovo Victory; bottom left and right, Shimano

Dura-Ace and SunTour Superbe Pro.

The Sugino Maxy used a square-tapered spindle with nuts to attach the cranks. Sakae, Takagi, and the Taiwanese crankset makers copied the Maxy spindle and it became a de facto standard. However, nut-type Maxy spindles didn’t look as classy as bolt-type Campagnolo spindles, so before long Maxy quality cranksets came with bolt-type spindles; this has become the new de facto standard.

There’s an ISO Standard for the 2-degree taper found on the square end of bottom bracket spindles. Most manufacturers nominally comply with this standard, but a lot of variations exist, including the batch to batch variations that occur with low-priced Brand X spindles. Stronglight, TA, and the old swaged Maxy-style cranks are larger than standard so they’ll bottom out if fitted on a standard spindle. The best-quality spindles are hollow to save weight.

______ Bottom Bracket Bearings ______

It doesn’t cost very much to put a plastic seal inside the cups of the bottom bracket to keep water out of the bearings; in fact, most cranksets now come with semi-sealed bearings. This plastic seal removes one of the major advantages of bottom bracket sets that make use of sealed cartridge-type bearings. However, cartridge bearings have the additional advantage of allowing the chainline to be moved. Phil Wood makes the best quality bottom bracket set with sealed cartridge bearings. Specialized and SunTour also offer bottom bracket sets with sealed cartridge bearings. ( TABLE 2 shows which cranksets come with seals. “Part.” means “partial seal” and refers to the screw thread that Campagnolo provides in lieu of a seal on their cranksets to keep out road grit.)

I don’t think that the industrial ball bearings used in cartridge-type bottom bracket sets are necessary for crankset service. Such bearings are designed to handle a constant high-speed load, whereas, bicycle cranks turn very slowly and the load placed on them varies. I believe that the cup-and-cone bearings that use eleven ‘A-inch loose balls or nine caged balls are, in fact, ideal for crankset service. Incidentally, the load capacity increases directly with the number of balls, so eleven loose balls have 22 percent more capacity than nine caged balls.

_______ Chainwheel Hardness _______

Top-quality cranksets come with chainwheels made from hard aluminum alloys. They bend less than inexpensive chainwheels and their teeth wear much longer. TABLE 2 shows chainwheel hardness where I could find the information. Chainwheel hardness is measured on the Rockwell B scale. (B-90 is a very hard aluminum alloy; B-60 is the soft annealed condition.) Top-quality chainwheels are usually thicker and made to tighter tolerances than chainwheels of lesser quality, so they run truer.

— Spacing Between the Outer Chainwheel and the Crankarm —

The distance between the outer chainwheel and the crankarm may seem like a trivial little dimension, but it has a major effect on front shifting. The early Huret, Simplex, and Campagnolo front derailleurs had cage sides that were parallel and fairly close together. These narrow cages allowed about two shifts on the rear and then you had to adjust the front derailleur because the chain was rubbing on the cage. In the 1970s, Shimano and SunTour widened the rear of their front derailleur cages so that you could make four or five shifts on the rear before you had to fine-tune the front derailleur. Now, just about everybody makes front derailleurs with wide cages. When these wide-cage front derailleurs are properly set up, the tail of the cage extends out beyond the outer chainwheel.

The gap between the outer chainwheel and the crank on 1970 cranksets was designed for the 1970 narrow-cage front derailleurs. Unfortunately, even though the old narrow-cage front derailleurs are obsolete, many cranksets still have narrow gaps between the crank and outer chainwheel. The TA Cyclotourist is the worst offender. If you have a crankset with a narrow gap, you have two options. You can either set up the front derailleur incorrectly so the cage just misses the crank and put up with poor shifting, or you can buy a properly designed crankset with a wide gap.

In theory, the narrow gap prevents the chain from wedging between the crank and the chainwheel if you overshift. In practice, a small stud on the outer chainwheel or on the crank works much better to prevent wedging, even with narrow chains. TABLE 2 shows chainwheel to crank spacing. Anything over 0.375 inch is adequate for a double. A triple should have 0.425 or so.

_______ Chainwheel Spacing _______

The spacing between chainwheels is rarely a problem on double cranksets. The front derailleur is simply adjusted to push the chain firmly from one chainwheel to the next. But triples are different. On a triple you have to feel your way from the outer chainwheel to the middle chainwheel, and it’s possible for the chain to “freewheel” on top of the middle chainwheel until you “kick” it over with the front derailleur. This problem is worse with narrow chains and with half-step gearing. With crossover gearing, the chain has farther to drop down to the middle chainwheel, so the problem is less likely to arise.

The solution to this problem is slightly narrower spacing between the two outer chainwheels on half-step setups. The magic spacing for trouble-free half-step shifting is about 0.275 inch. The crankset makers have trouble providing this because they have to design their chainwheels to please us gear freaks who often mix and match outer and middle chainwheels.

The spacing on many Stronglight cranksets is on the wide side. On the other hand, spacing is not terribly critical on cranksets that use Shimano Biopace chainwheels, because these elliptical chainwheels are free from the chain freewheeling problem. Variations exist between brands in spider thickness, chainwheel thickness, and where the teeth are centered in the chainwheel cross section. You may encounter spacing problems if you mix and match different brands of chainwheels. Sorry about that!

__________ Crankset Standardization __________

You would do well to consider the standardization issue before you buy a new crankset, because cranksets spotlight the worst features of the bicycle’s lack of standardization. There are two different bottom bracket widths: 68mm and 70mm. There are five different threads: English, Italian, French, and two kinds of Swiss. Each crankset comes with six to ten different spindle lengths to accommodate the two bottom bracket widths as well as single, double, and triple cranksets. The spacing between the bearing races on the spindles varies depending on the thickness of the cups. The taper of the spindles varies from maker to maker. There are even three different dust cap thread sizes, so bike shops have to have three different crank removers. The ISO thread standard is 22mm dia. X I pitch. The old Stronglight size was 23.5mm dia. x 1 pitch. TA is 23mm dia. x I pitch.

To complete the frustration, there’s just a smidgeon of commonality Al most everyone uses eleven ¼-inch ball bearings. On a good day, Shimano cranks might fit onto a Campagnolo spindle, which might fit into Sugino cups, and the chainwheels might fall on the proper chainline. But on most average days, nothing interchanges properly. Even if you buy an all-Shimano bottom bracket set, you’ve got to properly specify the bottom bracket width and threading and pick the right spindle length. Sutherland’s Handbook for Bicycle Mechanics (4th ed.) devotes roughly 20 pages to the subject of bottom bracket inter changeability. (When it takes 20 pages, it’s really non-interchangeability.)

Where does all of this leave you if you want to replace your crankset with minimum hassle? First, buy your crankset complete with bottom bracket set. Second, buy your crankset from a pro bike shop and have them do the installation. Third, buy an English-threaded frame, if you can, to avoid about half of the frustration. If you want to keep your costs down and reuse your existing bottom bracket, just accept the fact that you won’t know if your new crankset will fit until you try it.

________ Bolt Circle Standardization _______

Here comes the second verse of the crankset standardization song. The bolt circle diameter determines which chainwheels fit on which cranks. Over the last decade, six bolt circles have gained wide acceptance and have become de facto standards. With the exception of the Campagnolo C-Record, Victory, and Triomphe cranksets, all of the racing and touring cranksets shown in TABLE 2 use the six standard bolt circles listed in TABLE 3.

All of the standard bolt circles have more than one maker and they’re widely distributed. Everything else is bastard. If you buy a bastard bolt circle, you’re at the mercy of the maker and the importer for replacement chainwheels. If your crankset uses a bastard bolt circle and the maker goes out of business, as Takagi recently did, you may have no source of replacement chainwheels. To help you make your decision about a new crankset, let’s talk about the six standard bolt circles.

TABLE 3. Standard Bolt Circles

Campagnolo Record (144mm)

In 1968, Campagnolo reduced the size of the bolt circle on their Record crankset from 151mm to 144mm to allow the use of 42- instead of 45-tooth inner chainwheels. Such was Campagnolo’s power in those days that 144mm promptly became the new racing standard. More than a dozen makers now use the 144mm bolt circle. It’s an excellent choice if you race and if a 42-tooth inner chainwheel isn’t too big for you.

Shimano Dura-Ace (130mm)

About five years ago, it became apparent that 42 teeth was a bit big for a racing inner chainwheel. The widespread use of 12-tooth sprockets allowed racers to produce their desired High gear with smaller outer chainwheels, so proportionately smaller inner chainwheels and freewheel sprockets could be used to produce the desired Low. A smaller bolt circle was thus needed to permit the use of a smaller inner chainwheel. To meet this new demand, Sakae, Stronglight, Sugino, SunTour, and Takagi have all adopted the 130mm bolt circle, which Shimano has used on their racing cranksets since the early 1970s. When Campagnolo developed two new cranksets to meet the same need they assumed that it was still 1968. They chose to introduce two new bastard bolt circles, 135mm and 116mm. Reducing the size of chainwheels and sprockets saves weight, but more importantly, it pro vides more 1-tooth jumps on the freewheel.

Sugino Maxy (110mm)

The Sugino Maxy 110mm bolt circle, which takes a 34-tooth minimum chainwheel, is the only intermediate bolt circle that makes any sense. Five years ago, when it was used on Sugino’s five-arm Maxy and Mighty Tour cranksets, it was just one of three fairly common intermediate bolt circles competing in the low-price sport touring market. Then in 1982, Sugino introduced the Aero Tour triple crankset, which used 110mm for the outer and middle chainwheels and 74mm for the inner chainwheel. It became the favorite of the mountain bikers. I waxed enthusiastic about this combination in the May 1983 issue of Bicycling. Soon Sakae, Takagi, and Specialized were making Aero Tour clones. The real breakthrough came in 1984 when Shimano adopted 110- and 74-mm bolt circles for their triple cranksets. Now there’s de facto standardization with five different makers.

Stronglight 99/100 (86mm)

Stronglight and Sakae make cranksets using the 86mm bolt circle, which takes 28-tooth minimum chainwheels. It makes a nice triple that has all three chainwheels attached with long bolts. It also makes doubles for gear freaks who like wide-range combinations like 44/28. Stronglight is maintaining this bolt circle in production. Sakae is now emphasizing the 110mm and 74mm combination.

TA Cyclotourist (80mm)

The 80mm bolt circle is a link with the past. I include it as one of the six standards for sentimental reasons and because there are so many in use it’s a six-hole bolt circle that has been around since the 1930s. It goes with a five-pin bolt circle that attaches the outer chainwheel to the crank. There used to be a dozen manufacturers making five-pin cranksets. Now only TA survives with their Cyclotourist touring triple crankset.

Sugino Aero Tour (74mm)

I first saw 74mm bolt circles on Avocet and Ofmega triple cranksets in 1981. Five holes were drilled and tapped in the spider arms and inner chainwheels as small as 24 teeth could be bolted onto studs. I immediately made up a 50/45/24 triple and dropped my low to 19 inches. The problem with these two cranksets was the 144mm outer bolt circle. Few mountain bikes would accept a 42-tooth middle chainwheel. When Sugino picked the 74mm bolt circle for the Aero Tour crankset, its future was assured.

________ Crankset Makers ________

We will complete our discussion of cranksets with a look at the major crankset manufacturers.

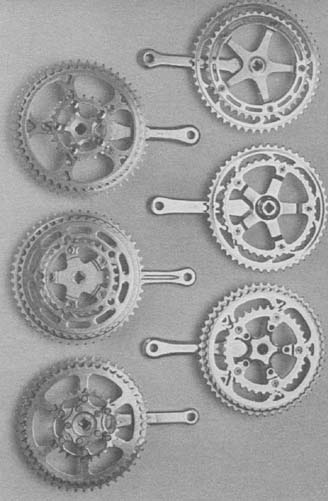

PHOTO 2 Six standard bolt circles shown on cranksets fitted with the smallest

us able inner chainwheel: top left to right, Campagnolo Record with 52/42

chainwheels (144mm), Shimano Dura-Ace with 50/39 chainwheels (130mm), and

Sugino Aero Tour with 52/47/34 chainwheels (110mm); bottom left to right,

Sugino Aero Tour with 52/47/24 chainwheels (74mm), Stronglight 100 with 50/45/28

chainwheels (86mm), and TA Cyclotourist with 50/45/26 chainwheels (80mm).

Campagnolo

Campagnolo’s crankset terminology is tricky. It isn’t easy to master all of the subtleties and impress your bike freak friends. Campagnolo is determined to call their top crankset “Record” regardless of the confusion. Virtually every one else calls it “C-Record.”

Prior to 1985, Campagnolo used different model names for cranks, chainwheels, and bottom bracket sets. The old cranks were called “Record” in all models, until Campagnolo renamed them “Nuovo Record” in 1986. Nuovo Record (née Record) chainwheels have an inner ring of metal. Super Record chainwheels have the ring removed to save weight.

There were three bottom bracket sets for Nuovo Record cranksets: Record, Nuovo Record, and Super Record. (You can feel for Campy’s renaming problems here—Nuovo Record and Nuovo-Nuovo Record I remember when Chevron introduced a super premium gasoline and the old premium was called “Supreme.” Same kind of problem.)

The old Record bottom bracket uses plain cups. The Nuovo Record cups have spiral grooves to keep out water, which requires different spindles, since the cups are thicker. Super Record uses a titanium spindle and special cups with small-diameter ball bearings. Nothing interchanges between the three versions. If I read the catalogs correctly, there are two new bottom bracket sets for C-Record and Triomphe/ Victory.

Campagnolo Nuovo

Record cranks with Nuovo Record or Super Record chainrings make a splendid racing crankset. It’s used by more than half of today’s professional riders. It has been copied by a dozen makers, the sincerest form of flattery. If you’re buying a new Campagnolo crankset, I recommend Nouvo Record.

The C-Record is an absolutely gorgeous crankset and it’s very rigid. Just realize that when you purchase it you’re buying a bastard 135mm bolt circle. The new Triomphe and Victory cranksets have a different bastard 116mm bolt circle. (Actually, Campagnolo perpetrated the foul deed a few years earlier with the Gran Sport crankset.) If you buy a C-Record, Victory, or Triomphe, you’ll be forced to buy your chainwheels from Campagnolo. I’m not paranoid about this. If the super bike of your dreams needs C-Record, go for it. (At $400 a copy, who needs a second source of chainrings?) Victory and Triomphe are another matter. With their 35-tooth minimum chainwheels, they’re not suitable for loaded touring. The sport tourer can get more for his money elsewhere.

Sakae

Sakae is the volume supplier of standard-quality cranksets. They make a vast range of cranksets for bicycles in the $150 to $300 price range. Sakae was the first major user of melt-forging. They make top-quality racing cranksets in both of the standard racing bolt circles, but they haven’t been too successful competing with Campagnolo and Shimano for the premium market. Sakae makes touring triple cranksets in both the Stronglight 99/100 and the Sugino Aero Tour bolt circles, with the emphasis on the latter. They’ve concentrated on the OEM bicycle makers rather than the mail-order houses or the bike shops. They’re making a major effort to sell their FXC series in the aftermarket. The FXC-200 double uses the 130mm bolt circle. The FXC-T310 triple uses the 1 lOmm/74mm bolt circles. Both are available with oval chainrings.

Specialized

The Specialized racing crankset is made by Sugino. It uses the latest recessed crank design, which allows a shorter, stiffer spindle. It has very hard chainwheels for longer wear. The Specialized touring crankset is a Sugino Aero Tour clone. The bottom bracket sets include 0-ring seals.

Shimano

Until about ten years ago, Shimano made only top-of-the-line Dura-Ace cranksets to compete with Campagnolo. They left the lower-priced market to Takagi. As derailleurs and chains became more sophisticated, Shimano felt they had to make the entire drivetrain. They now have a complete line of cranksets. Shimano concentrates on innovation. Five years ago they introduced a whole range of aerodynamic AX cranksets featuring “dropped” Dyna-Drive pedals. This enjoyed a brief spurt of popularity and then Shimano moved on to other designs.

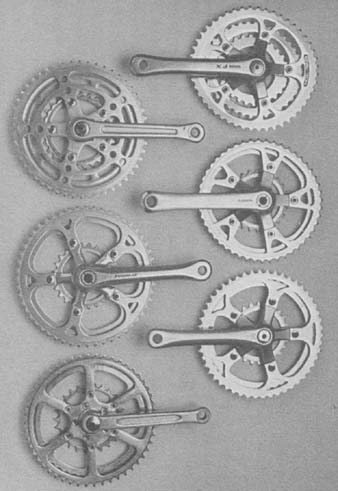

PHOTO 3: Touring cranksets: top left to right, Sakae FX with 48/38/28 chainwheels,

Shimano Biopace with 48/44/26 chainwheels, and Specialized Touring with 50/45/24

chainwheels; bottom left to right, Stronglight 100 with 50/45/28 chainwheels,

Sugino Aero Tour with 52/47/24 chainwheels, and TA Cyclotourist with 50/45/26

chainwheels.

There are six Shimano lines in the replacement market: Dura-Ace, Sante, 600 Ultegra, and 105 for the racers and Deore XT and Biopace for the tourists and mountain bikers. Shimano has decided that racers want conventional equipment, so Dura-Ace is a conventional crankset with all of the current features. The Sante and 600 Ultegra cranksets are nearly identical to Dura-Ace, but with a bit less polish. The 105 is Shimano’s economy melt-forged crankset.

Shimano’s two touring triples, Deore XT and Biopace are built around Biopace chainwheels. There are now two versions of Biopace. The newer Biopace II is a bit closer to round than the original Biopace. I’ve pedaled Biopace chainwheels for three years or so. They make a small, positive difference, especially if you pedal in the saddle all of the time and at a fairly low cadence. If you stand up to pedal an old Biopace, it feels a bit like walking down a staircase. I’ve got round chainwheels on three bicycles and the two versions of Biopace on the other two. There’s not a great difference among them.

The elliptical shape of the Biopace chainwheels does have a positive effect on shifting. Biopace triple cranksets shift beautifully. The chain never rides on the middle chainwheel.

Stronglight

Five years ago, Stronglight was another sleepy French company resting quietly in the sun, waiting for the Japanese to eat their lunch. They printed a new catalog every few years even if it was the same as the old one. Then Stronglight woke up and reacted to the competition. They restyled their entire line and introduced handsome new models with new model numbers. Models 106 and 107 use the 144mm bolt circle. Models 103 and 200 use the 130mm bolt circle. Models 106 and 103 are cast; models 107 and 200 are forged. Model 100 is the updated version of the old model 99 triple crankset. It uses the 86mm bolt circle, which is the smallest that mounts all of the chainwheels on one bolt circle.

Sugino

Sugino and Sakae are similar Japanese companies. They make a complete line of cranksets with the major emphasis on the lower-priced OEM market. Over the years, Sugino has made excellent copies of virtually all of the popular premium cranksets: Campagnolo Record, Shimano Dura-Ace, Stronglight 99, and TA Cyclotourist. This is a good thing because it provides a reasonably priced second source. The Maxy was Sugino’s first breakthrough and the Aero Tour was their second. The Sugino 75 is a special top-of-the-line model to celebrate their 75th anniversary. Sugino cranksets are available with a nice feature called “Autex,” which is a combination attaching bolt, dust cap, and F crank remover. All you need is a 6mm Allen wrench to remove your cranks. Shimano has a similar feature that they call “One-Key Release.”

____ SunTour ____

SunTour decided that they had to market a complete gruppo to compete with Shimano. SunTour’s cranksets are made by Sugino. SunTour makes a top- quality sealed-cartridge bottom bracket set. The Superbe Pro, Sprint, and the clone are all excellent values.

___ TA ____

TA stands for Specialities TA. They’re the sleepy French company that hasn’t yet reacted to the Japanese competition. TA makes a range of cranksets but the Cyclotourist is the only model that is widely distributed in the USA. Twenty years ago, if you wanted a wide-range triple crankset, you bought a Cyclotourist. Today, you’ll get exactly the same crankset, complete with the softest chainwheels available, the narrowest gap between the crank and the outer chainwheel, and 11 bolts to hold the whole assembly together. In TA’s favor, they have the widest range of crankarm lengths (from 150mm all the way to 185mm) and chainwheel sizes (from 69 to 26 teeth). The Cyclotourist bolt circle is unique, but Nervar, Shimano, Stronglight, Sugino, and many other companies make (or made) chainwheels that bolt onto the five-pin TA crank.

__________ Everybody Else __________

Edco, Galli, Gipiemme, Mavic, Nervar, Ofmega, Omas, and Zeus all make good-quality racing cranksets. All, except Zeus, use the Campagnolo 144mm bolt circle. They all also face a Catch-22 situation. The bicycle makers and bike stores won’t handle their products until they are widely used and they can’t become widely used until they are fitted by the OEMs and are carried in the stores.

__________Favorite Cranksets __________

This one is close. My favorite racing crankset is the new Shimano Dura Ace. It’s got the right bolt circle, a sealed bottom bracket set, and it’s beautifully finished. My favorite touring triple crankset is the Sugino Aero Tour, however, the copies from Shimano and Specialized are so close that you can buy the one that catches your eye.