Although the bicycle is the most efficient means of transportation known to man, that efficiency depends on the rider’s wise and correct use of the ma chine. The bicycle has the potential; man provides the energy and the intelligence to make it work.

When you are out there with your loaded touring bike facing 50 miles or more of rolling terrain, you need to be cycling as efficiently as possible. This is especially true on an extended tour where you are putting on high mileage over a varied countryside day after day. The ability to make full use of your energy resources without waste is what separates the apparently effortless cyclist from those who seem always on the edge of exhaustion.

Two factors directly affect the efficiency of the rider/bicycle combination: gearing and cadence. First, let’s dispel a myth. Gears don’t lessen the amount of work necessary to move a bicycle. They do make that work easier, or sometimes harder, depending on the degree of understanding the rider has about the gears.

-Single-Speed Gearing-

On a single-speed bicycle the gear consists of a front chainwheel and a rear cog connected by a chain. As the rider turns the pedals attached to the crankarms, the chainwheel revolves. That motion is transferred through the chain to the rear cog, which then turns the rear wheel. This propels the entire machine and rider. The amount of force the rider must apply depends on such things as his weight, the weight of the bicycle and its load, wind resistance (the major factor at speeds over ten miles per hour, the rolling resistance of the tires on the road, the frictional resistance of the various moving parts on the bicycle, the road surface and the type of terrain. The steeper the incline the more energy (work) is needed to move the bike and rider up the hill.

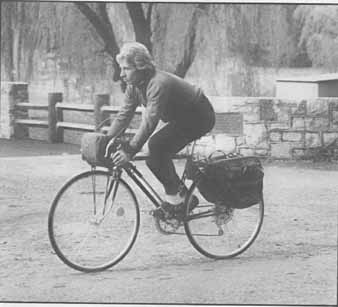

With a touring load it’s even more important that the rider learn the

techniques which encourage efficient cycling.

On the single-speed bicycle, the front chainwheel is much larger than the rear cog, having many more individual teeth. Since the rear is smaller, it turns several times for every revolution of the chainwheel, an immediate savings in energy output by the rider. The rider can vary his pedaling according to the speed desired and the conditions under which he is traveling. On a flat section of road, turning the chainwheel at 75 revolutions per minute (rpm), the bicycle will move along at a constant speed of about 15 mph. As the rider approaches a hill things change rapidly. Either the pedaling (chainwheel) slows or the speed reduces, usually both. As the hill is climbed, chainwheel revolutions might slow to about 40 and the speed to about 7 mph. At the same time the rider is putting out a great deal more energy with each revolution of the chainwheel.

At the top of the hill things change once again. Suddenly the chainwheel revolutions are increasing dramatically, requiring less energy on the pedals as speed increases proportionately. Some where around 25 mph the rider’s legs are flailing away at an attempted 120 rpm and there is no longer any force being applied to the pedals at all. The rider then finds it easier to coast until the next level terrain where the pedaling begins again.

As long as the hills are not too steep, the rider is in good physical condition and is happy to coast downhill, the 1-speed bicycle is satisfactory. However, given increasing steepness of terrain, there comes a point where the rider becomes physically incapable of propelling the bicycle up grades at a pace faster than he can walk. Considering the amount of energy poured into the effort, walking in fact becomes easier than riding.

-Multi-Speed Gearing-

This is where the multi-speed (gear) bicycle comes in, be it anywhere from 3 speeds to 18 speeds. The actual amount of energy required to propel the bicycle does not change (all other factors remaining constant), but through the proper use of the gears the production of that energy becomes easier for the rider of the multi-speed.

Instead of only one rear cog as on the single-speed, the multi-speed derailleur bicycle has several differing sizes of rear cogs. On 10 or more speeds there is more than one chain- wheel, also with differing sizes. The rider has the ability to change the gear ratio of the bicycle by switching the chain among various-size cogs and chainwheels with the derailleurs. The rider can change the speed of the chainwheel in relation to the speed of the rear wheel without changing the number of revolutions his legs must perform. In effect, the rider has instantaneous choice of a number of gear situations to meet the variety of riding conditions encountered.

Consider how a 10-speed would take the same section of road as a single-speed. On the flat stretch the rider still feels comfortable turning the chain- wheel at 75 rpm at a speed of about 15 mph. Being on a 10-speed makes no difference at this point. However, as a hill is approached the speed begins to drop but the rider does not have to accept an increasingly hard-to-push, decreasing rpm of the chainwheel. He simply shifts to a lower gear to maintain a comfort able, less exhausting (more efficient), 75-rpm chainwheel speed.

There is no change in speed going up the hill between the 10-speed and the single-speed, rather the change is in the condition of the rider. As the hill becomes steeper, the rider continues to shift to lower gears (providing there are enough) while maintaining a comfort able chainwheel rpm of 75 or so.

When the rider crests the hill and begins to descend, he shifts to higher gears as downhill speed increases, maintaining pressure on the pedals with an efficient chainwheel speed. The higher the gear, the less likely it’s that the rider will have to coast. The important thing to remember is that it takes the exact same amount of energy to propel either the single-speed or the multi-speed bicycle up a hill, all else being equal. What changes is the pro portion of work done by the machine and the rider. The multi-speed can be shifted according to the conditions rather than having to change the speed of the motor (the rider). Using proper shifting technique, the multi-speed is simply easier to ride because the rider can maintain smooth, easy revolutions without wasting motion, expending huge outputs of energy on the uphill, and wasteful out-of-control flailing or coasting on the downhill. The hill is no less steep, it just feels that way to the rider. Such efficiency is especially important on long tours where your energy and enthusiasm must remain constant over a long period of time.

-The Importance of cadence-

The primary function of gears on a bicycle is to allow the rider to maintain a good cadence (a smooth, comfortable chainwheel rpm). To better understand the importance of cadence, consider the motion of a fast-running animal. It’s all grace and flow, no wasted motion at all, nothing to detract from the on-going energy of the action. Wasted, irregular motion is rare. When a cheetah is ob served in slow motion, it seems hardly to be working at all. For comparison, go down to your neighborhood bicycle trail on a warm, sunny Sunday afternoon and observe. You will see a wide variety of style and rhythm, the sad majority of which is rough and irregular. You can almost see the energy falling by the wayside. Granted, if people are having fun and getting some exercise, so what?

But the point is to develop your touring efficiency through awareness and practice. So look once more at the normal recreational rider.

Two things contribute to a rough and irregular riding style. One, as we covered in section three, is a saddle that is too low. This causes a jabbing leg action where the rider is first pushing with one leg, then the next, rather than making a smooth, continuous circular motion. It almost seems like the pedal is pushing the leg back up for the next assault instead of the leg doing the work all the way around. Adjusting the saddle helps.

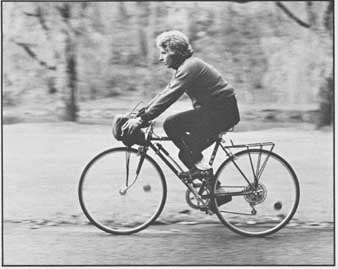

In this instance, the saddle is too low, which will cause the rider

to “jab” at the pedals rather than follow through the pedals with continuous

rhythmic motions.

Cadence is another factor that influences riding style. Most of those recreational riders are pushing a very high gear, which requires them to turn the pedals at a slow and painful rpm. In stead of flowing along like fast-running animals, they are powering each stroke using legs like pistons instead of fly wheels. There is frequently a pause after each downstroke to recover for the next. For the occasional, short-distance weekend rider; fine (although that may be partly why he or she is only a short- distance rider). But for you — the serious touring cyclist — a rough riding style can not only shorten your day on the road, but it can also lead to serious muscular and joint difficulties, especially in the knees.

Developing Cadence

How do you arrive at a proper, efficient, comfortable riding cadence? An easy method is to first make sure your bicycle is in proper adjustment (see section three). Then find a good route that includes a section of road about a mile long that is relatively flat and wind-free if possible. Now, put some miles on your bike over this route until you feel comfortable and relaxed as you ride it. Fasten a watch with a second hand to your handlebars or wrist. Once you feel you are riding in a normal, comfortable manner on the flat section, count the number of times your right pedal reaches the bottom of its stroke for one full minute. Do this several times to arrive at an average count. This figure represents your chainwheel rpm, which is also your own individual cadence.

You are exhibiting good, efficient cycling form if your cadence is in the range of 60-80 rpm. If you are under 60 rpm you have some work to do to develop your best touring potential. Above 80 you are doing something called “spinning”; it’s a good training technique that helps to develop elongated muscles and loose joints, but is not too comfortable as a normal riding style. If you are spinning you are probably not just an occasional bike rider, either.

Try doing some spinning if your cadence is below 60 rpm to help you get the feel of pedaling faster. As your legs lose the feeling that they are flying out of control, you can begin to drop your cadence to within the 60-80 rpm range and exert more pressure on the cranks. Then it will feel more normal to you and your legs will have had some beneficial exercise. You will also find yourself pedaling more efficiently.

There is no one best cadence for which to strive; each rider must find his or her best individual pace. The majority of noncompetitive riders level out at between 60-80 rpm, but if you are a little below or above yet and feel that you have a smooth, comfortable riding style then don’t worry about it. If, however, you are below about 55 or so, try some corrective action to pick up your pace.

As you develop and regulate your cadence on flat terrain, begin to consider the hills. On a single-speed bicycle you simply have to muscle your way up as the incline increases, trying to maintain your cadence with sheer will and muscle power. But on your 10-speed (or more) you have the option of maintaining your cadence through the use of gears rather than muscle. This is where gearing and cadence come together. The one simply facilitates the other; gears seem to flatten mountains and reduce head winds because they al low you to maintain your own comfort able cadence no matter the changing conditions.

-Know Your Gears-

In order for gears to perform this al most magical function, the rider must be able to shift the gears properly and at the right time. To do that the rider must first understand what gearing is all about. It doesn’t do any good to have a 10-speed if you are using only three or four of your gears. If, in addition, you are selecting those gears in a hit-or- miss fashion with no specific progression from gear to gear, you are losing much of the advantage of a multi-speed bike and you are most likely losing cadence as you make your shifts. It doesn’t make any sense to invest $250- $1,000 in a fine touring machine only to ride it as though it were a single-speed or 3-speed. Taking the time now to learn proper gearing can mean that your hours on the road will be longer, more pleasant and less tiring.

A common misconception among owners of multi-speed bicycles is that there are 10 usable gears on, a 10- speed, or 15 on a 15-speed, etc. The assumption is immediately made that you simply shift the rear derailleur five times in one direction, change the front chainwheel with the derailleur, and shift the rear five times in the opposite direction. Not so.

The best way to understand the shifting process is to chart the gears on your own bicycle. This will take a little time, but once done you will have a clearer picture of gearing. First, get a pencil and paper, a rag for cleaning your hands, and some sort of marking device such as a crayon. Start by looking closely at your chainwheel. On most models there is an engraved number on one side of each chainwheel that tells the number of teeth (the size). Check for that number. If you can’t find it, or you just want to check it out for your self, make a mark where you begin and count the total number of teeth on each chainwheel. Write those numbers on your sheet of paper , for example, 42 and 52. Next (this can get messy) count the number of teeth on each of your five rear cogs attached to the freewheel on the rear wheel. You will arrive at a series of numbers such as; 14-17-20-24-28. These are the sizes of your rear cogs. After cleaning your hands, sit down and get out your calculator unless you have a head for math; we are going to do some figuring to make up your gear chart.

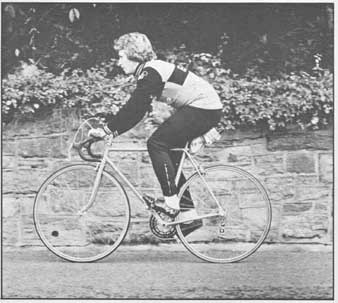

A common mistake by a beginning cyclist is to push too high a gear,

which results in rapidly tiring the leg muscles. Usually a rider demonstrates

that the gear is too high by pushing through the pedal motions. Sometimes he

will lean from side to side as he gives disproportionate emphasis to a particular

pedal cycle.

When you shift your 10-speed bike, you move the chain into a variety of combinations of chainwheel and cog, thus changing the specific gear ratio. The mystical derailleur is simply a piece of metal attached by cables to your shifting lever, in order to move the chain physically from one chainwheel to the next or from one cog to the next, depending on whether it’s a front or rear derailleur. These various combinations are easier to deal with if we give them individual numbers rather than at tempting to classify them with left-front chainwheel to second-from-the-inside or second-largest cog, and so on. So we will determine their numerical value (the size of the gear) by using a formula that breaks down the gear ratios into gear inches. The formula is as follows:

The number of teeth on the chainwheel times the bike wheel size divided by the number of teeth on the rear cog equals the gear in inches. For example, given a front chainwheel of 42 teeth and a rear cog of 28 teeth on a bicycle that has 27- inch wheels (look on the tire if you are not sure of your wheel size), you will arrive at a gear of 40.5 inches.

42x27= 40.5 inches

This gear inch is relative, allowing us to make comparisons among the various combinations of gears possible on a multi-speed bicycle. It’s not the distance your wheel travels in that particular gear. It originates from the old high- wheeler, penny farthing-type bicycle where the pedals were attached directly to the large drive wheel; a comparison of gearing between bicycles could be made by determining the diameter of the large wheel. If you want to know how far your bicycle will travel with one complete turn of the chainwheel in any one specific gear combination, just multiply the gear inch by pi (3.1416). In our sample gear of 40.5 inches the bicycle would travel 127 inches along the road for every complete turn of the pedals.

Figure the formula for a 52-tooth chainwheel and a 14-tooth cog, just for practice. Your figures should look like this:

52 x 27= 100.2 inches 14

100.2 x 3.1416 = 314 inches of ground travel

Looking at these two sample gears, it’s apparent that the 40.5-inch gear is relatively low with only 127 inches of ground travel, while the 100.2-inch gear is higher with 314 inches of ground travel. That is what gears are all about; the actual distance you can travel per one revolution of the chainwheel or pedals.

On steep inclines you would gear down to your 40.5-inch gear to compensate for gaining less ground per revolution due to the resistance of going uphill. Your chainwheel would be turning faster in relation to your rear wheel than in a higher gear, making for an easier ascent. Going down, you switch to your 100.2-inch gear so you can turn the chainwheel a smaller number of times in relation to your rear wheel; this allows you to keep pedaling as your speed increases, rather than having to coast.

Now back to your individual gear chart. Determine your own gear inches by using the formula with the figures you wrote down for your chainwheels and cogs. It might look something like the following:

Cogs— 28 24 20 17 14

Chainwheel< 42 40 47 57 67 81 >Gear

Teeth 52 50 59 70 83 100 Inches

Incorporating these into a straight-line gear progression you come up with:

40-47-50—57-59-67-70—81 -83-100.

So now you have ten gears, right? Yes. But ten useful gears? No. When you use the smallest chainwheel in front and the smallest cog in the rear, the chain is at an extreme angle (from the inside to the outside). On our sample bike that would be 42/14, the 81-inch gear. This angle is so extreme that it will wear components (chainwheel, chain and cog) at a fast pace if used often. You can sometimes hear the friction as you ride in this combination. Try it briefly on your own bike to see for your self. The same is true for the opposite extreme, the largest chainwheel and the largest cog; 52/28 on our sample bike, gear 50. These two acute chain angles are not recommended due to wear, noise and shifting difficulties.

The straight-line progression now looks like this with eight gears remaining: 40-47— 100.

There is additional problem. The 57-inch and the 59-inch gears are very close together, a difference of only 6 inches in actual ground travel. Also, when shifting properly from lower to higher, the 59-inch gear requires that both front and rear derailleurs be shifted (double-shift). To gain only 6 inches on the ground you must shift both derailleurs, a difference you would hardly feel. The logical thing would be to skip that gear, going on to the 67- inch gear while remaining on the 42- tooth chainwheel. That now leaves a total of seven useful gear combinations:

40-47-50-57- 100.

One more double-shift occurs be tween 67 and 70. If we are dropping the 59-inch gear because it’s so close to the 57 and requires a double-shift, why not do the same with 70? There are only 10 inches of ground travel difference between 67 and 70, but skipping 70 means quite a jump to 83. It really depends on you and the conditions of your ride. You have the option of skip ping it or working the double-shift. These midrange gears are used extensively in touring; sometimes when conditions are right the double-shift is no problem and well worth the gain. The option is yours, but notice that your 10- speed is now somewhere between a 6- and 7-speed. The chainwheel/cog combinations for usable gears in our sample bike look like this:

42/28 42/24 42/20 42/17 52/20 52/17 52/14 |

= 40 = 47 = 57 = 67 = 70 = 83 = 100 |

Do this with your own gear progression, noticing where there are double- shifts and which are the two extreme- angle gears you want to ignore. Don’t be surprised if you end up with six or seven gears as we did above. The main thing is that you now have a clear idea of your gear capacity, progression, limitations and options.

You may want to make up a permanent gear chart to attach to your bike for reference while touring. We have done it for years; it’s especially helpful if you have more than one bicycle. The easiest way to do this is to type or print the chart on a gummed label, then at tach it to the handlebar stem or to the top tube near the headset. Use indelible ink or cover it with transparent tape to keep it from getting wet.

The trick is learning to distinguish, as you ride, exactly which cog and chainwheel you are using. Then you can quickly determine which gear combination you are in and what the next one is in progression. Susan has always had difficulty using the gear chart as she is more receptive to size comparisons — largest, middle, smallest — than to what she considers an arbitrary number for each cog and chainwheel. The problem was even more complex on the 15-speed she frequently rode until she took a set of color Highlighter pens to her chart. Using red for the largest, yellow for the middle, and blue for the smallest, she reports that her chart had instant visual meaning to her as she rode.

Run through your gears several times to become acquainted with your shifting progression before you actually get out on the road. To do this at home, put your bike in a stand or raise the rear wheel by tying a rope to a rafter or tree and attach it to your bicycle seat. With the rear wheel oft the ground you can shift through the gears as the crank is turned by hand. ( You might need a friend to help with this procedure.) After a little practice you will be ready for the road.

Once your gears are familiar to you, you can be o the proper gear combination with your cadence to develop a smooth cycling style. Practice on a relatively flat roadway until you know automatically when your cadence is right. Then begin to tackle small in clines, gradually increasing the variety of terrain until your shifting becomes so automatic that you can maintain your cadence no matter what the hills and wind are doing. When you reach that point, you are riding at your maximum efficiency. Touring long distances daily will then feel as normal and comfortable to you as riding to the store for a bottle of milk. Well, almost.

Riding into a strong head wind can be more depressing and demoralizing than climbing an endless hill. A good, steady cadence along with gear shifting to match the force of the wind can re duce the devastating effect of a head wind.

- Gearing Range-

After all of this, if you are still having trouble developing a smooth riding and shifting style, the fault may be with your machine rather than with you. Now might be the time to examine the gearing range on your bicycle. Gear range is a highly individualistic matter; no one should be pressured into someone else’s idea of the “ultimate.” Here are some things to consider when looking at your own gear range.

Double-shifting is a pain (having to change both front and rear derailleurs to obtain a desired gear). It’s not too bad in the middle and upper gears when you are pedaling along with a good deal of inertia going for you, but a double-shift in the lower gears can be your undoing while struggling up a steep hill. Check to see if you have a simple, straightforward shifting pattern with few double-shifts, especially in the lower gears. Halfway up the Rocky Mountains you will really appreciate it.

Another aspect to check out is the number of gear inches between shifts. You needn’t translate them into ground travel inches; it’s best to get used to thinking only in gear inches. The general practice is to keep about 10 or 12 inches between the various gears with wider gaps in the very low and very high ends. When using a fairly tight range like the one in our sample — 40 to 100 — you can have gears closer together through the midrange where most of the riding takes place. In the more widely spaced gear ranges, such as from the high 20s to over 100, difficulties arise that require decisions based on personal preference and experience. If you have not toured extensively with a heavy load, you will have to rely on others’ advice and experience. Presumably that is one of the reasons you are reading this guide.

We prefer low gears in the mid- to upper 20s with 5- to 10-inch jumps be tween gears, especially when touring with heavy loads in mountainous terrain. We like 10- or 12-inch jumps in the middle gears and 15 or more inches be tween the higher gears. In our experience, a steep grade is the toughest thing out there in the touring world. We need all the help we can get to maintain a smooth, non-exhausting pace to get up one.

Our preference for closely spaced lower gears and average jumps in the midrange necessitates -either super jumps in the high gears or lower high gears to begin with. The latter has been our choice; we find it well suited to our needs. Our highest gear is in the mid 90s because we feel we have no business going faster than that downhill with a loaded bike. When we have toured with high gears in the 100s, we tended to use them; frequently arriving at the bottom with trembling arm muscles, weak knees and overheated rims.

The most controversial gearing subject is usually how low the lowest gear should be. Some cyclists spend hours debating this point, becoming very emotional in the process. What is frequently lost sight of is the element of personal need. The bike club president may well prefer a bottom gear no lower than 42 because the bulk of his riding is done in the suburbs with nothing heavier than a lunch in his or her panniers. He may also stand up off the saddle to “honk” up every hill on the Sunday ride. You have to decide if that is practical for you on your fully loaded touring bike when camp is 20 miles farther and 2,000 feet higher than you are right then. Honking on a loaded bike ruins your cadence, wastes energy through sideways motion and can do in your lungs. About the only thing going for it’s the wonderful alleviation of that persistent pain in your bottom as you slide free of the saddle for awhile.

Gear your bike as low as you need to maintain your own comfortable pace carrying the load you expect to carry on tour. If necessary, pack up with five- pound bags of flour and go out to some hills for a trial run. You will find out quickly if your low gear is low enough. How will you know? By how soon you have to start walking. If you would rather use our experience for what it’s worth, here are our recommendations:

Stick to a low gear in the mid- to upper 20s for serious mountain travel with a heavy load (anything over 35 pounds); the lower to mid-30s for most standard touring with a moderate load. But it’s best to find out for yourself before you set out cross-country or around the world.

It’s not difficult to change your gear range if you decide it’s not suited to your needs, but don’t rush into it. Change only for the sake of change rarely brings improvement. Carefully analyze your gear chart and riding style for the gears you find most useful, those you seldom use and for convenience in shifting. Once you have these elements clearly in mind you can sit down to determine what changes are necessary and which is the easiest way to do it. Use the chart for finding the various gear possibilities -- you won’t have to work the formula each time.

In order to make changes in your existing gear pattern, you will either have to change one or more of the rear cogs, or one or both of the chain- wheels. The changes are not difficult to make, providing you have the proper tools and know-how, but there are secondary problems associated with any gear change. These usually involve derailleur capacity.

Front and rear derailleurs have built-in limitations as to the size of cog or chainwheel combinations that can be handled. Before you decide on a specific desirable gear combination, check to make sure that your present derailleur can handle it. In other words, if you now have a 28-tooth large cog in the rear and you want to change to a 32- tooth cog, be sure your rear derailleur has the capacity for the increase. You must either talk with a competent bike mechanic about it, search YouTube or the Internet, or look at an issue of Bicycling magazine. Find an excellent article entitled “All About Derailleurs” in which is listed over 100 front and rear derailleurs and their various capacities. You might want to keep that article beside you for reference as you are planning out your gear changes.

Most people find it easier to replace some or all of their rear cogs than to replace their chainwheels. Even with the common 42/52 chainwheels, how ever, you can gear down to a 33-inch low gear with a 34-tooth large cog. That would require a large-capacity derailleur (G.S. or G.T. model); if your bike doesn’t have one you will have to purchase it to make the change. Anything over 30 teeth will probably require the wide-range rear derailleur, meaning an investment of $12-$45.

Our own choices among the many excellent rear derailleurs are, in order of preference, the Sun Tour VGT, Shimano Crane GS and Campagnolo Rally.

The VGT is the lowest priced, the Campagnolo Rally the highest. In wide- range front derailleurs we have had success with the Sun Tour Cyclone, Shimano Titlist and Campagnolo Record. These are not the only high-quality, wide-range derailleurs, but they are widely available and have proven them selves to us through the gamut of touring conditions and gear ranges.

When changing your rear cogs you must also consider the make of free- wheel on your bicycle. Since some have limited capacities and are difficult to find replacement cogs for, you might have to obtain a whole new freewheel and-cog assembly (cluster) to get what you want.

We have limited our freewheel se lection to the Sun Tour (Maeda) Pro Compe and the Perfect in order to suit our low-gear preferences and keep things as simple as possible. The only difference between them seems to be in the color. Each is readily available so cogs are easily replaced (an important consideration while touring), low in price, simple in design and highly reliable. For those especially strong riders who expect to be carrying very large loads, Sun Tour also makes a Tandem freewheel which uses the standard Pro Compe or Perfect cogs. There are over a dozen types of freewheels, so make sure you know what you want and what you are getting. A competent, knowledgeable bike-shop crew can easily make all the necessary changes for you, but be sure to tell them what sort of gearing you want to begin with so there are no surprises.

TABLE: Gear Chart for 27-inch Wheel

Number of Teeth on Chainring vs. Number of Teeth on Sprocket

Gear ratios not shown above may be calculated as follows:

Gear = number of teeth on chainring / number of teeth on Sprocket x diameter of rear wheel in inches

We will assume now that you have a gearing system suited to your personal requirements and that you have developed your cadence and shifting to a smooth degree. Let’s look into a few of the finer points of efficient cycling that will be of help to your touring.

Riding as smoothly as possible is the major factor associated with efficiency in cycling. By learning and concentrating on the proper shifting sequence along with developing a steady, 60-80 rpm cadence, you have already done most of the work. This isn’t to say there will never be any variation in your cadence; rather as you become more skilled and experienced you will find you rarely vary from your norm by more than a plus or minus 5 revolutions no matter the cycling conditions.

Cyclists frequently interrupt their cadence when they shift. It pays to learn to anticipate your shifts before they be come necessary or even impossible without breaking into your rhythm. You have probably seen two riders closely paced going up a hill, only to see one suddenly drop behind dramatically, never to catch up. It isn’t that one was stronger; more likely one was anticipating the shifts while the other waited too long only to lose all upward momentum while trying to get into a lower gear. The opposite extreme is when a rider shifts down too soon on approaching a hill, sometimes going into the lowest gear because he knows it will be needed be fore getting to the top. Then you see a wild spinning of pedals with dramatic drop in momentum until finally the hill matches the low gear; you will slow down much sooner than would have been the case had the shifting been done properly.

As you approach a hill, wait to shift just until you begin to feel increasing resistance to your stroke, then drop down only one gear at a time while maintaining your normal cadence. It takes practice. As you shift the gear, momentarily ease up on the pedal. You can’t expect the derailleurs to move the chain while you are applying full pressure to it. The trick that comes with practice and experience is to learn just how much to let up pressure to quickly make the shift without breaking your cadence or losing momentum.

There is sometimes a tendency to overshift, that is to move the derailleur (the chain), a little too far on the cogs. With experience you will learn to automatically adjust the derailleur to center it on the cog when you overshoot. A sudden noise in the area of a derailleur made by the chain rubbing against the adjoining cog indicates an improper alignment that can be quickly cured by moving your shift lever slightly in one direction or the other. It doesn’t take much, just a slight adjustment will do.

As you are progressing up a hill, dropping into lower gears one at a time, you will eventually reach the point — if the hill is long and steep enough — where you arrive at your last, lowest “granny” gear. From there on you will be exerting steadily increasing pressure on the pedals and your cadence will necessarily begin to slow down. Things are getting tough. By this time you should have your hands in the full drop position on your handlebars and be leaning forward. This lets you bring your strong back and arm muscles into play and to literally pull your way up the hill. One thing to watch for here is to guard against shifting your weight from side to side as you pull. Such swaying back and forth is a great waste of energy and tends to make your course erratic. Try to maintain a stable body position and a straight line of travel.

A good way to check on your upper body stability is to suspend a small object from a string around your neck (a simple pendant necklace would work fine). Glance at it as you cycle up hills; it should remain hanging straight down, not swinging from side to side.

When the going gets tough, some of the toughs start “honking,” standing up off the saddle to pressure their way up. Try to resist the temptation. Honking is a real strain on your legs, arms and body in general. With good gearing you can conquer almost any hill sitting down. When all is lost and you are al most at a standstill, swallow hard, ignore your pride, step off your bike and walk. You will be amazed at how good it feels to use different muscles for awhile, not to mention how nice it’s to really look at the view. If you are worried about what your better-conditioned (or more stubborn) cycling companions will say, whip out your camera and take a picture. They’ll never know the difference.

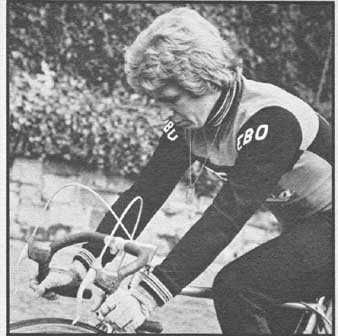

To check on your upper body stability, suspend a small object (a pendant

necklace would work). Glance at it as you cycle up hills. If your body position

is correct, it should remain hanging straight down, not swinging from side

to side.

One final technique in efficient cycling is called ankling. It’s a difficult maneuver to learn only by reading about it; it’s even harder to teach by writing about it. Basically, ankling is the maintenance of constant pressure on both pedals throughout the entire 360-degree rotation using a maximum number of muscles in your legs, ankles and feet.

In order to do it successfully, your bicycle must be adjusted to you exactly (see section three) and you must be using toe clips and straps.

Beginning at the top of the pedal cycle, the 12 o’clock position, the foot is flat or horizontal. As the pedal passes the 3 o’clock and approaches the 6 o’clock position, there is a digging into the toe clips. As the pedal passes the 6 o’clock position the foot is definitely tilted downward and there is a feeling of pulling, or clawing, of the foot backward on the pedal. As the 9 o’clock position is reached the foot is beginning to flat ten out again until at the 12 o’clock position it’s again horizontal and ready to start downward once more. This continual digging and clawing, done in a smooth, steady manner for the entire rotation, should employ all the muscles possible in the lower leg, ankle and even the foot. Don’t be surprised if you develop sore ankle joints, calves and in- steps as you are learning and practicing the process. Persevere, your body will soon adjust to this new development.

Proper ankling will add greatly to your overall efficiency because you are applying power throughout the entire rotation of the chainwheel, spreading the effort over a greater number of muscles, and sharing the load, thereby in creasing the energy output as well.

After writing this section, Tim went out for his usual daily ride to put ankling into practice as though for the first time. He reaffirmed that it’s definitely much easier to do than to write about. Simply concentrate on maintaining pressure throughout the entire chainwheel revolution by digging down and clawing back up. Chances are, if your bike was properly adjusted in the first place, you have been ankling all along and were not even aware of it.