APPENDIX I

European Frame Builders Additional information about products offered by the frame builders in this book can be obtained by writing directly to the builder. However, to expedite your inquiries the following U.S. importers can be of assistance.

Condor Georgetown Cycle Sport Wildwood Manor Shop ping Center Bethesda, MD 20014 301-530-9011 Paris Sport Cycle 186 Main Street Ridgefield Park, NJ 07660 201-641-0087 Bob Jackson, Mercian Bikecology Bike Shops 3910 Nebraska Avenue PO Box 1880 Santa Monica, CA 90406 213-829-7681 Jack Taylor Fulton Street Cyclery 3038 Fulton Street San Francisco, CA 94118 415-387-4978 Bud's Bike Shop 217 West First Street Claremont, CA 91711 714-626-3285 Roberts Cycle Company 7053 North Clark Street Chicago, IL 60626 312-274-9281 Raleigh

Raleigh Industries of America, Inc.

1170 Commonwealth Avenue Boston, MA 02134 617-734-0240 Guerciotti, Pogliaghi, Woodrup Ten Speed Drive Imports, Inc.

PO Box 2152 1403 South Patrick Drive Indian Harbor Beach, FL 32937 305-773-8654

Gitane Gitane Pacific 4925 West 147th Street Hawthorne, CA 90250 213-644-8651

Peugeot Cycles Peugeot U.S.A., Inc.

540 East Alondra Boulevard

Gardena, CA 90247 213-774-5454 or 213-537-3600

Cinelli

Ultima

PO Box 37426

Houston, TX 77036

713-661-9132

APPENDIX II

American Frame Builders

The following is a list of some of the experienced American frame builders who have acquired, or are developing, good reputations through the quality of their frame building. We apologize for any omissions; we assembled the list from our personal experience or recommendations from persons whose opinions we respect.

Francisco Cuevas c/o Paris Sport Cycle 186 Main Street Ridgefield Park, NJ 07660 Bruce Gordon Cycles 27729 Clear Lake Road Eugene, OR 97402 Custom Cycles by Wm.

Sampson 5052 Corbin Avenue San Jose, CA 95118 Jim Redcay PO Box 62 Washington Street Lambertville, NJ 08530 Colin Laing Racing Cycles 917 East Fort Lowell Tucson, AZ 85719 TREK Bicycle Corporation 268 Jackson Street Waterloo, WI 53594 Bill Boston Cycles 38 Franklin Street PO Box 114 Swedesboro, NJ 08085 Strawberry Racing Cycles, Inc.

510 NW Third Avenue Portland, OR 97209 F. M. Assenmacher Light weight Cycles 104 East May Street Mount Pleasant, MI 48858 Proteus Design 9225 Baltimore Boulevard College Park, MD 20740 Caylor Frames 519 Kansas Avenue Modesto, CA 95350

APPENDIX III

Recommended Brazing Procedures

1. Before the tubes are assembled the ends should be degreased and cleaned with emery over the area which is inserted into the lug. This ensures that the brazing material makes good contact with the parent metal. (Reynolds 531 cycle tubes are sent out free from scale and rust, and protected with an anticorrosive oil, but if by some mischance during transport or storage some rust should form, this must be completely removed.)

2. When the tubes are fitted into the lugs and pegged, care should be taken that the assembly is not in a state of stress.

3. Brazing should be carried out in the following clockwise sequence:

a. Bottom bracket

b. Down tube and head tube joint

c. Head tube and top tube joint

d. Top tube and seat tube joint.

This sequence obviates the danger of a stress raiser being created at a major shock point.

4. When brazing frames made from Reynolds 531 tubing, the joints should be preheated, and after brazing the cooling should be controlled. Brazing must be carried out in a shop free from drafts.

5. We prefer the torch brazing method as this reduces the risk of overheating the material and causes less distortion, thus reducing subsequent setting times. The hearth method of brazing can also be used, but whatever method is used, great care must be taken not to overheat the material, or to heat too large an area of the tube. Overheating will lead to burning or to brass inclusion (where the molten brass or bronze enters the grain of the steel), either of which will make the tube brittle.

6. Setting, when necessary, should always be done cold.

7. Most proprietary brazing materials can be used satisfactorily, but we recommend the use of brazing materials with a melting point of about 850°C. (1,562°F.).

•("Courtesy of TI Reynolds)

APPENDIX IV

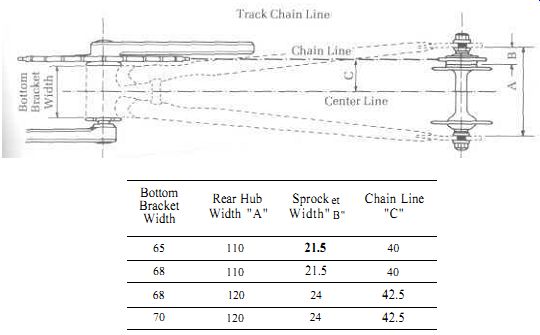

Chain Lines Bottom Bracket Width 65 68 68 70 Rear Hub Width "A" 110 110 120 120 Sprock Width" 21.5 21.5 24 24 et B" Chain Line "C" 40 40 42.5 42.5

----------

----------

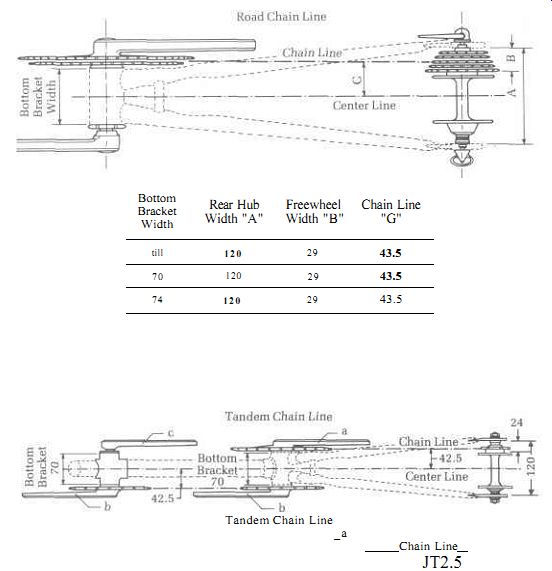

Bottom Bracket Width Rear Hub Freewheel Chain Line Width "A" Width "B" "G" till 70 74 120 120 120 29 29 29 43.5 43.5 43.5 Tandem Chain Line

_ a

Chain Line JT2.5

-b a

Track Right-hand Standard Crank b Track Right-hand Crank with Left-hand Thread c Track Left-hand Crank with Right-hand Thread