The primary problem in describing bicycle tubing is that the differences between the available types of tubing are extremely subtle. They are primarily compositional. For instance, Reynolds, a major manufacturer of bicycle tubing, has decided to use a small amount of manganese in their tubing which subtly alters its characteristics. The primary change in the tubing as a result of the addition of manganese is realized in the actual frame-brazing process rather than a difference in the ride characteristics of the frame. Columbus, another major manufacturer of bicycle tubing, adds chrome to their tubing. Again, this slightly varied tubing composition does not result in noticeably different ride characteristics as much as it changes the type of brazing methods that should be used on the frame.

If the average bicycle rider cannot readily tell the difference in tubing, then why is bicycle tubing such an important factor in the choice of a top-quality bicycle? There are two primary answers.

One, to make a butted bicycle tube (the "butting" process is explained in detail in this section) is extremely difficult and requires far greater production costs than a standard drawn (or plain gauge) tube. Although the butted tube only provides marginally different specifications from the standard tube, the strength characteristics for the weight of the tube are important enough to the serious cyclist to justify the greatly increased cost. It is important, therefore, for the consumer to be able to identify the type of tubing in a bicycle to insure that he or she is getting the proper tubing for the price.

Two, a high-quality double-butted tube that has been properly brazed has a considerably longer life and will retain its strength for a far greater period of time than an inexpensive tube that has been improperly brazed. This is one important reason why so many people are interested in custom frames. The key to understanding tubing is to understand the processes that the builder uses when he is actually building a frame. One of the most important aspects of frame design is matching the proper brazing techniques and design with the appropriate bicycle tubing.

Are there any real differences between the varying brands of bicycle tubes? One very obvious difference is the design variance that exists between individual tubing manufacturers. For in stance, Columbus pioneered the Italian section fork blade which provided vastly improved handling characteristics of the bicycle.

Other than specific design variations like fork blades and availability in certain gauges, the basic frame tubes are very similar in their ability to perform.

Why are only two tubing manufacturers, Reynolds and Columbus, included in the following pages? The decision had been based on the fact that the vast majority of all highly respected master frame builders use either Reynolds or Columbus tubing.

Although there are other tubes made in France, Japan, and in the United States, for several reasons Columbus and Reynolds remain the two top choices of the master frame builders.

First, there is a great deal of history that supports the popularity of the two large tubing manufacturers. Both were pioneers in the research and development of the modern-day bicycle tube. Simply, they started before anyone else did and they came up with lasting and successful designs. It should also be obvious that the majority of the most famous frame builders in the world are located in close proximity to the major tubing manufacturers. As the reputations of the builders grew, so did the reputations of the tubing manufacturers. Another factor that greatly contributed to the continued popularity of the two tubing manufacturers, is the tendency for builders to have little desire to try alternative brands of tubing. The two popular tubings are of sufficiently high quality to virtually eliminate the desire of any builder to try other products.

Only recently, as a result of the bicycle boom, has any experimentation in using other tubing occurred. This resulted from the inability of the tubing manufacturers to increase production as fast as sales demanded. Why haven't other tubing manufacturers become involved in the marketing of high-quality bicycle tubing? The reason is primarily due to the incredibly large investment in heavy machinery that is required. The world's bicycle market is very small when compared to the potential steel use for other industries such as the automobile or the construction industry. Without the large market potential and subsequent large sales volume, it simply isn't worth the manufacturers' investment in the heavy machinery and development costs that would be required.

Because of the nature of this section with its highly technical content, the casual reader is advised to skip to section 3 describing Campagnolo bicycle components and the use of their special tools. For those persons interested in the technical side of bicycle frames, the rest of the section provides both a history of the two major companies and technical information regarding the composition and working requirements of the bicycle tubes.

TI Reynolds In the 1880s, Mr. Alfred Milward Reynolds was obsessed with making lightweight bicycle tubing, but met failure after failure when the tube continually buckled at the ends. In an effort to obtain the necessary strength, he fitted slightly smaller size tubes at the ends of the tubing to serve as reinforcing liners.

Although the liners provided the necessary strength, Reynolds felt that additional tubing was an unnecessary additional weight.

In 1887 he invented the process he called butting, patented the process and founded the Patented Butted Tube Company in 1898. At that time, only bicycle tubing was manufactured.

Everyone recognized the benefits of the butted process and, after the patent expired, other tubing companies started to use the process. The following is an explanation of the butting process provided by TI Reynolds:

For lightweight machines, whether for touring or racing, a "cold drawn seamless" tube is required-one which starts life as a solid ingot which is pierced hot, either in a hydraulic press, or by running it between inclined rollers which force it over a pointed mandrel, thus "pushing the hole through the bar." Further hot-rolling results in a "hollow" or "bloom," already looking like a tube, which goes to the seamless tube manufacturer to be cold drawn down to the diameter and gauge required for our cycle frames.

At every stage, each bloom is annealed (i.e., softened by heating), and pickled in acid to remove scale.

Then one end is reduced to a smaller diameter, known as the "tag," to enable it to pass through the drawing die. After lubricating with a special compound of oil, soft soap, and other ingredients, it is ready for drawing.

Draw-benches come in a variety of sizes, some being mighty monsters over a hundred feet long, with the die-plate nearly halfway along.

The bloom is slipped over a shaped plug on a long mandrel bar, fixed to the end of the draw-bench, the tag is pushed through the die and gripped relentlessly by serrated steel jaws, known in the tube trade as "dogs." These are mounted on a "wagon," running on a track containing a large continuous multiple roller chain, to which the wagon is automatically locked when the dogs have gripped the tag, thus drawing the tube through the die, and over the plug on the end of its mandrel. As this has moved to a position within the die, the metal is in effect squeezed between the die and the plug, thus reducing both diameter and thickness, and at the same time increasing the length. Several such "passes," interspersed with annealing and pick ling operations, are necessary before the tube is the right diameter and gauge, accurate to within three thousandths of an inch, for the manufacture of frame tubes, forks, and stays for your new bicycle.

In 1923, the name of the company was changed to the Reynolds Tube Company, Limited. The cycling tubing at this time had been called "HM" and was of high manganese content and low molybdenum content. A major change occurred in 1935 when 531DB tubing was developed. Reynolds always points out that 531 is said as "five-three-one" not five hundred thirty-one or five thirty-one.

Figure 2-2: The machine that "butts" the tube.

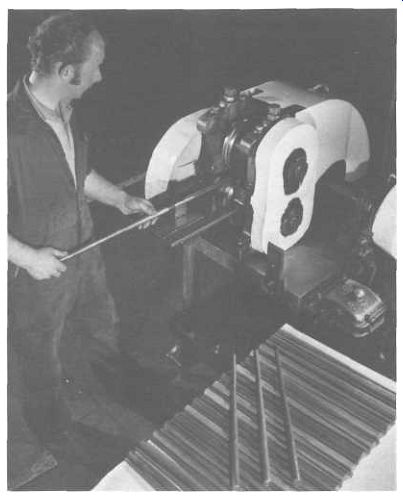

Figure 2-1: The machine at TI Reynolds that actually makes the tubes. Three tubes are drawn simultaneously (at the top). One end is reduced to a smaller diameter and pulled through the drawing die and over the shaped mandrel. The tube is pressed through this process several times before the final diameter and gauge are reached. The three tubes visible at the bottom are in an inter mediate stage of completion.

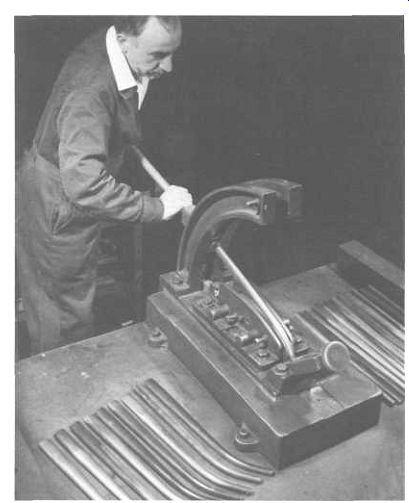

Figure 2-3: This method of tapering stays and fork blades is seldom used

now. TI Reynolds found it difficult to locate and train persons with the

necessary "touch" to feed the tubing to the machine by hand.

Consequently, the process is now handled entirely by machine.

Figure 2-4: No machine has been developed to bend fork blades with more

accuracy and care than this workman. All fork blades are raked by hand!

Reynolds 531 is a manganese-molybdenum tubing--the 531 refers to the ratio of the major elements it contains. The people at Reynolds are also quick to point out that unlike the advertisements of some bicycle companies, Reynolds 531 is not chrome molybdenum. Reynolds believe that their manganese molybdenum tubes have greater ductility than chrome molybdenum tubes and, consequently, they will retain a greater percentage of their strength after brazing. While there is some chrome in the tubing to effect the proper physical properties, it is in substantially smaller quantities than would qualify it to be called chrome molybdenum tubing.

As road surfaces continued to improve, and the reliability of the tubing remained unchallenged, Reynolds developed a new lighter gauge called Reynolds 531SL (Special Lightweight).

A major change occurred in 1975, when the new 753 tubing was introduced. In spite of reduced wall thickness (it's only .3 mm.) and lighter weight, the new tubing is 50 percent stronger than 531! The 753 tubing is very special tubing that has not been made generally available yet. Because of the special nature of the tubing, only pre-evaluated builders will be able to buy 753.

Reynolds has distributed two sets of the tubing to some "master" builders for assembly in a test frame. The frame must be sent to Reynolds for destruction testing. If , and only if , the frame has been correctly brazed, 753 will be available to those builders. The tubing requires extremely close tolerances since the only ap1proved method of brazing is with silver.

In the United Kingdom, only Bob Jackson, Harry Quinn, and TI Raleigh have received approval to build with 753. In the United States, Proteus Design (the only U.S. Reynolds agent) had built a 753 frame and sent it to England for evaluation. In turn, Proteus Design has been approved to build with Reynolds 753. To give you an idea how light the tubing is, let's look at the approximate frameset weight of bicycles built with 531DB, 531SL, and 753.

Weights of frame with fork, seatstays, and chainstays:

531DB-5.5 lbs. (2.5 kg.)

531SL-5 lbs. (2.3 kg.)

753-4 lbs. (1.8 kg.)

In 1977, the Reynolds Tube Company, Limited changed their name to TI Reynolds because they make more than just bicycle tubes. The bicycle tubing division is only one of the three divisions in the continually growing company. One division manufactures the flash welded rims for the Rolls Royce Olympic engine used in the Concorde and another division manufactures hydraulic cylinders. The tubing division provided frame tubing for the now-defunct Jaguar XKE and they still make tubing for wheelchairs.

For the technically inclined, we have included the following information, provided by Reynolds, that details their unique fork blade construction. Recommended brazing procedures are found in Appendix III.

Figure 2-5: Any of these Reynolds 531 transfers signify that the bicycle

has been built with Reynolds tubing but the differences should be noted.

The first three indicate that the frame has butted frame tubes, seatstays,

and chainstays, and taper gauge fork blades. The following two indicate

that the frame has been built with Reynolds 531 butted frame tubes but

that the chainstays and fork blades used are from another manufacturer.

The last decal denotes that the frame has been built with plain gauge Reynolds

531 frame tubes plus 531 fork blades and chainstays.

Fork Blade Construction

Tapering a tube for a fork blade, chainstay, or seatstay, is a highly skilled task. Two steel rollers, one above the other, rotate so that the faces in contact with each other are moving towards the operator. In those faces are semi-circular grooves, matched to present a round hole, which progressively diminishes as the rollers rotate, then suddenly opens out to full diameter again. The full diameter is that of the tube to be tapered, and the length of the tapered groove in the rollers coincides with the required length of tapered tube.

As the full diameter faces the operator, he quickly pushes in the tube as far as he can. The rollers push it out again, but squeeze a little into the tapered groove.

As the full diameter comes round, so the tube is pushed in again, going in a little further on account of the small length already reduced in diameter. This is further reduced as the tube is pushed out again. The operation is repeated at the rate of about sixty strokes a minute until the tube reaches a pre-set stop behind the rollers.

All the time, while the tube is being pushed in and out, the operator is rotating it, to ensure that its soundness is maintained. A stay takes between a quarter and half a minute, according to length, and is afterwards trued up for straightness.

Fork blades are made this way, from round tubing, which is afterwards shaped to oval or D at the larger end if required. They are then bent round a former in a simple hand-operated bender. The tool looks almost primitive, but is very effective and accurate.

Modern road surfaces are generally good-but even so, if our front forks were rigid we would have a very uncomfortable ride, and use up so much energy absorbing the vibration in our arms that mileages would tumble and times would stretch alarmingly. So the front fork blades are curved to a carefully planned "rake" to provide resilience and so smooth out some of the road-roughness.

This is where Problem No. 1 crops up. The weakest point in a cycle tube is adjacent to the brazed joint, so we need the top of the fork blade to be rigid.

Now Problem No. 2.

When a tube is tapered, quite naturally its walls tend to thicken up as the diameter decreases.

So now we have a typical fork blade, where the top is of adequate thickness for rigidity, but the bottom is thicker than the top, thus partially defeating the effect of the rake, and killing some of the resilience! What can be done about this? Some cycle manufacturers use a lighter gauge fork blade to get the resilience, and put a liner in the top for rigidity, but by far the best solution is the taper gauge fork. You will remember how Mr. Reynolds invented the Butting process, whereby the wall thickness of a tube could be increased at one or both ends without affecting the outside diameter. You will also probably remember that a fork blade starts life as a straight parallel tube. We take a light gauge tube of the right diameter, put in a single butt with a long gradual change of gauge, and then taper the end with the thinner gauge. Bent to shape, we have the Reynolds Taper Gauge fork blade, with a wall thickness less at the resilient end than at the rigid end. The result is that road shocks are smoothed, and more energy can be devoted to making the wheels go round, farther, faster, or with less fatigue.

A. L. Colombo

Angelo Luigi Colombo started manufacturing tubing in 1924 for the aircraft industry. The production of double butted bicycle tubing began in 1930. Signore Colombo is now 86 years old but still comes to work two or three times each week. His son, Antonio, is the director of the company which has become, with TI Reynolds, one of the most sought-after tubes for light weight bicycles.

It is interesting that the engineers at Columbus feel very differently about chrome vs. manganese than those at Reynolds.

For instance, the only tube in the Columbus line that is carbon manganese is the "inexpensive" set. All of the top-of-the-line tubing is chrome molybdenum. The design intent at Columbus is high strength and high elongation since low elongation tends toward brittleness. Furthermore, they will not build tubes with less than .5-mm. wall thickness. They believe that oxidation during the brazing process can reduce the effective thickness of the tube by as much as .1 mm. They seem consistent in their beliefs, since even their "record" extra-light tubing is .5 mm. thick.

The specialties at Columbus are their fork blades and fork columns. Unlike TI Reynolds, they do not believe that a taper gauge fork is desirable. The Columbus fork is identified by its smooth curve and large section. This design responds to the

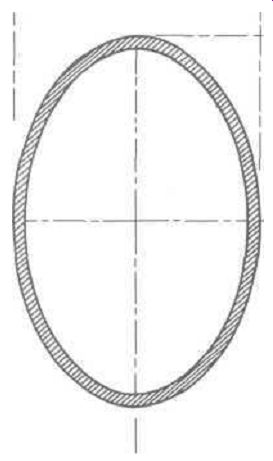

Figure 2-6: Cross-section outline, fork blade

made of Columbus tubing. The diameter and wall thickness are kept proportionate

to the bending stress throughout its length. Note that the ellipse of

the fork blade has an equal thickness.

Figure 2-7: Cutaway, Columbus fork column section.

... cyclist's need for strength while cornering without adverse amounts of road shock over bumps. The fork column is also unique with its two thicknesses and five helical ribs (similar to rifling in a gun barrel) designed to withstand enormous torsional forces without excessive weight (figure 2-7) .

As a result of the enormous popularity of the Columbus blades (they became known as Italian section forks), TI Reynolds has recently marketed blades of similar design. Since many of the English builders used Reynolds tubing on their frames, they had been unable to offer the Italian section forks. They now report that a very high percentage of their frames are built using the Reynolds Italian section forks. Many riders suggest that the Italian section forks do provide a considerably more comfortable ride and, at the same time, improved cornering power.

A new seatstay is offered by Columbus, and although it has not gained any popularity in this country, some Italian builders claim that it is extremely popular on the Continent. This stay has its largest outside diameter in the center of the tube. That is, the tube has a narrow section near the seat lug, increases to its maximum halfway down the stay, and then decreases to the same size section as the top where it is brazed to the fork end.

There are no additional advantages to the stay; it is produced for "aesthetic" appeal.

Now that we have reviewed the properties of the two major brands of bicycle tubes, the components that hold them together, and the elements of design that contribute to a good handling and strong bicycle, let's take a look at the steps that must be completed before the frame is ready for assembly. Since these steps require special tools, we have included a step-by-step guide to explain their use. The next section covers the history of the manufacturer of these tools--S.P.A. Brevetti Internazionali Campagnolo-the world's most famous name in bicycle components.