If your present rear derailleur is more than five years old, you have a treat in store for you. Today’s rear derailleurs are so much better behaved than their parents that they make shifting almost second nature; in addition, they’re rugged and reliable. If you install one of the new indexed shifting packages, you’ll find that you can shift on the rear just by pushing the shift lever to the next indexed setting. You can also downshift to a lower gear on a hill with a lot more certainty.

In the past decade, I’ve tested more than 100 rear derailleurs and written seven articles about them. During that period, derailleurs multiplied like amoebas. There are now a dozen derailleur companies and some of them make more than a dozen different models. Two recent developments, mountain bikes and indexed shifting, have dramatically changed the derailleur market.

Mountain bikers demand bulletproof, wide-range equipment. The old touring components weren’t good enough and Shimano and SunTour rushed in to fill the demand. If you’re touring with an old wide-range rear derailleur, you’ll be impressed with the superior performance of the new mountain bike models.

===

TABLE 1-- Racing Rear Derailleurs

1. I weighed rear derailleurs without hangers.

2. See the text under Maximum Freewheel Sprocket. The maximum sprocket is different depending on the drop of the derailleur hanger. I measured the racing rear derailleur using a hanger with a 1-inch drop. Swil catalog shows two maximum sprocket ratings a larger sprocket for normal shifting, and a smaller sprocket for Indexed shifting. I show the normal-shifting sprocket in parentheses.

3. I tested the racing rear derailleurs with a narrow-spaced seven-sprocket freewheel. The cable travel shown is the amount required to shift the derailleur from the smallest sprocket to the largest.

4. Huret, Shimano, and SurWour make complete indexed systems. The models shown as “yes” are those that they say are suit able. Campagnolo says that their Syncro indexed shift lever works with the C-Record, Super Record, Nuovo and Nuovo Triomphe rear derailleurs. It does, after a fashion. I show a “maybe” in these cases.

5. Cnt means that the cage pivot and the jockey pulley are on the same axis. Frw means that the cage pivot is located forward of the centerline of the two pulleys

6. The Nuovo Victory uses a three-position bushing instead of a screw for adjusting the mounting angle.

===

_______ Indexed Shifting Rear Derailleurs _______

Indexed shifting is a litmus test for rear derailleur quality. A rear derailleur that works well with indexed shift levers will shift splendidly with friction levers.

Indexed shifting has caused a major shakeout in the derailleur business. In 1987, Shimano and SunTour dropped about 30 derailleurs from their catalogs because they weren’t suitable for indexed shifting. Huret and the other small makers still make their old models, but the market is drying up. Campagnolo’s Syncro indexed shift levers work adequately with the newest Campy rear derailleurs, but the company is betting that serious bikers will continue to use friction levers.

Today, there are two kinds of rear derailleurs: current models that are suitable for indexed shifting and obsolete models that may or may not shift precisely enough for indexed shift levers. As I explained in section 4, indexed shifting works best with a completely coordinated gear train: rear derailleur, freewheel, chain, and shift levers. Thus, if you plan to buy a new rear derailleur, it makes sense to buy a model that’s suitable for indexed shifting, in case you decide to complete the conversion later.

= = =

TABLE 2. Touring Rear Derailleurs

1. I weighed rear derailleurs without hangers.

2. See the text under Maximum Freewheel Sprocket. The maximum sprocket is different depending on the drop of the derailleur hanger. I measured the touring rear derailleurs using a hanger with a 1.3-inch drop. SunTour’s catalog shows two maximum sprocket ratings a larger sprocket for normal shifting, and a smaller sprocket for indexed shifting. I show the normal- shifting sprocket in parentheses.

3. I tested the touring rear derailleurs with a wide-spaced six-sprocket freewheel. The cable travel shown is the amount required to shift the derailleur from the smallest sprocket to the largest.

4. Huret, Shimano, and SunTour make complete indexed systems. The models shown as “yes” are those that they say are suitable. Campagnolo says that their Syncro indexed shift lever works with the Victory LX rear derailleur. It does, after a fashion show a “maybe” in this case.

5. Cnt means that the cage pivot and the jockey pulley are on the same axis. Frw means that the cage pivot is located forward of the centerline of the two pulleys.

6. The Victory LX uses a three-position bushing instead of a screw for adjusting the mounting angle.

= = =

_____ Derailleur Testing ____

In 1979, I built a derailleur testing machine. It’s simply a gear motor in stalled on an old bicycle frame to turn the crank at a steady 70 rpm. A pointer attached to the shift lever and a protractor let me read exactly where each shift takes place. I run each rear derailleur up and down the scale on each chainwheel. After each shift, I adjust the shift lever until the chain is exactly centered on the freewheel sprocket. This is just what you do when you quiet the “coffee grinding” at the rear. The difference between the shift point and the re-centered point measures the derailleur’s shifting precision.

A precise-shifting rear derailleur requires minimum lever movement after each shift. A sloppy-shifting rear derailleur requires large adjustments after most shifts. I measure how much the derailleur shifts “early” or “late” on each gear and I use the measurements to calculate the “shifting performance.” ( Section 4 talks about the reasons that rear derailleurs shift early or late.) In the calculations, I score late shifting much more harshly than early shifting. The shifting performance score is included among the ratings in tables 1 and 2.

Over the years, I’ve also installed 50 or so different rear derailleurs on my bicycles to check their performance. The road tests have corroborated the machine’s results. Interestingly, when designers from Shimano and SunTour visited my home workshop, they knew exactly what I was doing because they use sophisticated versions of my testing machine to design better derailleurs.

Indexed shifting requires rear derailleurs that shift precisely, so that after the indexed shift the jockey pulley is centered under the sprocket. All of the new Shimano and SunTour rear derailleurs that are designed for indexed shifting are very precise. They would all have scored “excellent” or “very good” with my old tests. Indexed shifting also works best with early-shifting rear derailleurs.

TABLE 2. Touring Rear Derailleurs

PHOTO 1 Derailleur testing machine.

I still use the testing machine to test the new rear derailleurs designed for indexed shifting, but I run the tests differently. I used to test all rear derailleurs with a standard wide-spaced 5-speed freewheel and a standard chain. Now I use a narrow-spaced 7-speed, 12-13-14-15-16-17-18 freewheel for the racing rear derailleurs, and a wide-spaced 6-speed, 13-15-18-22-26-32 freewheel for the touring rear derailleurs.

I use the maker’s recommended freewheel and chain for each system so I’m testing the performance of the total system, not just the rear derailleur. I used the following freewheels and chains for the rear derailleur tests:

• Campagnolo: Regina America freewheel and Regina CX-S chain.

• Huret: Maillard freewheel and Sedisport chain.

• Shimano: Dura-Ace twist-tooth freewheel and Narrow Uniglide chain.

• SunTour: Winner Pro freewheel and SunTour Pro chain.

In my old tests of racing rear derailleurs, I used a freewheel with the maker’s maximum recommended sprocket. Shimano pointed out that the 1- tooth steps of a “straight block” freewheel are harder on rear derailleurs than 2- or even 3-tooth steps. I checked and they were right. That’s why I used a 12- to 18-tooth freewheel to test the racing rear derailleurs.

The tests take four steps. First, I confirm that the total package shifts precisely with its indexed lever. Second, I disconnect the derailleur from its indexed lever and measure exactly where the shifts take place with a calibrated friction lever. Third, I measure the indexed lever’s shift points. (The results of this test are shown.) Finally, I compare the fit between the rear derailleur’s shift points and the indexed lever’s shift points. This measures how much wear and mis-adjustment the system can tolerate. This new rating, indexed shifting performance, is shown in tables 1 and 2.

____ Major Rear Derailleur Design Features ____

Section 4 lists a number of factors that affect rear shifting performance. Most of them involve freewheels, chains, cables and casings, and rear hangers. These factors interact in various perverse and barely predictable ways. No wonder it took so long to invent better rear derailleurs! (The principal parts of a rear derailleur are identified in FIG. 1.)

The ideal rear derailleur moves the jockey pulley in a precise path just in front of the sprockets, regardless of the size of the sprockets or the chainwheels. The designer has four main options available to accomplish this objective.

____ Number of Pivots ______

Rear derailleurs can have one or two spring-loaded pivots. Most of today’s single-pivot derailleurs are based on Thllio Campagnolo’s classic, simple, rugged Gran Sport, which was introduced in 1950. The top pivot doesn’t have a spring. It just allows you to pull the derailleur back to remove the back wheel. The lower spring-loaded pivot rotates the cage and wraps up chain. Campagnolo’s single-pivot design was copied by SunTour, Huret, Galli, Mavic, Ofmega, Zeus, and many other manufacturers, It’s basically a narrow-range design and it has serious limitations for wide-range shifting.

The double-pivot design is based on the Simplex U model invented by Lucien Juy 50 years ago. Two spring-loaded pivots are used. The spring in the top pivot pulls the derailleur backwards. The spring in the bottom pivot rotates the cage, winding up chain and pulling the derailleur forward. The two springs and the geometry of the cage keep the jockey pulley close to the sprockets. When Shimano copied the Simplex design, they improved performance by dropping the parallelogram under the top pivot, making it more nearly horizontal. Shimano calls this the “Servo-Panta” mechanism. Most Simplex rear derailleurs now have a horizontal parallelogram. The new SunTour and Huret indexed shifting rear derailleurs incorporate double pivots and dropped parallelograms.

Shimano seems to understand the spring interactions of double-pivot derailleurs better than anyone. Shimano SIS rear derailleurs have more tension in the top springs than Huret, Simplex, or SunTour double-pivot models.

____ Cage Pivot Location ____

The pivot for the derailleur cage can be located on the centerline between the two pulleys, or in front of the pulley centerline, or right at the jockey pulley. The original Campagnolo Gran Sport rear derailleur had the cage pivot halfway between the two pulleys. The first Campagnolo Record rear derailleur, introduced in the early 1960s, moved the pivot in front of the jockey pulley. This allows the jockey pulley to swing in an arc back and down as it climbs onto larger sprockets. Almost all current rear derailleurs use this design. The location of the pivot significantly affects the shifting character of the derailleur.

The Huret Jubilee and the Campagnolo Victory touring derailleurs mount the cage pivot on the same axis as the jockey pulley. The jockey pulley moves straight in and out, so it has to be positioned well forward and just low enough to clear the largest freewheel sprockets. The advantage is that rear shifting isn’t affected by front shifts. The disadvantage is that the jockey pulley is mounted too low for the small sprockets. The old SunTour VGT was a fixed jockey pulley derailleur. It shifted as well as it did because of the slant parallelogram. Because the jockey pulley has to be mounted so low (to clear the large sprockets), this class of derailleur tends to shift late on the small sprockets.

_______ Slant Parallelograms ______

SunTour patented the slant parallelogram in the early 1950s. By mounting the parallelogram pivots at an angle, the jockey pulley moves down a ½ inch as it moves inward. All SunTour rear derailleurs have slant parallelograms. It’s the basic technical reason for their fine performance. Because of SunTour’s patent, the other makers had to use straight parallelograms. When the patent expired in the mid-1980s, Shimano quietly incorporated slant parallelograms into their new derailleurs. The 1988 Huret ARIS and Campagnolo Chorus derailleurs have slant parallelograms. (Tables 1 and 2 indicate which derailleurs have slant parallelograms.)

_________ Angle Adjustment Screw _______

When you bolt the rear derailleur onto the hanger, a tab on the derailleur engages the claw of the hanger. This sets the mounting angle, which in turn locates the jockey pulley. This angle is very important to single-pivot rear derailleurs and important to double-pivot rear derailleurs, because it deter mines the chain gap. If the derailleur has an angle adjustment screw, then you can raise or lower the jockey pulley to match the largest sprocket.

You can also compensate for variations in the claw angle of the hanger. Claw angles aren’t standardized. The other makers of rear dropouts kind of copy Campagnolo’s rear hangers, but they don’t do a very good job. Even Campagnolo doesn’t do a very good job of copying Campagnolo because the different Campagnolo rear dropouts and separate hangers have different claw angles.

Shimano provides an angle adjustment screw on all of their indexed shifting rear derailleurs. SunTour provides what looks like an angle adjustment screw on their new rear derailleurs, but it’s actually a stop rather than an angle adjuster. Huret provides an accessory adjuster for the Jubilee and the Duopar.

The Campagnolo Nuovo Victory and Victory LX rear derailleurs have a three-position bushing that lets you adjust the mounting angle. No other Campagnolo derailleur has an angle adjuster. If you want to change the angle, you have to file the claw on the hanger. Even if your bicycle has a proper Campagnolo hanger, the angle that’s right for a 28-tooth sprocket isn’t right for a 12- to 18-tooth straight block. (Table 1 and 2 show which rear derailleurs have an angle adjustment screw.)

FIG. 1 Rear derailleur nomenclature. Upper pivot (can be spring-loaded)

_______ Chain Gap _________

An ideal rear derailleur has a chain gap between 1 and 2 inches in every gear. Within this range the derailleur will shift precisely and predictably. Tables 1 and 2 show the minimum and maximum chain gap measured with the extreme combinations of chainwheels and freewheels. (I discussed chain gap at greater length in section 4 because it’s so important to indexed shifting.)

The indexed shifting rear derailleurs from Shimano, SunTour, and Huret are very similar. Either they read each other’s mail, or their design packages are giving the same answer. Their new rear derailleurs all have two spring-loaded pivots, slanted parallelograms, and cage pivots about an inch in front of the jockey pulley.

Minor Design Features:

In addition to the four major features, the designer has several other design options.

Cage Pusher Plate:

The early rear derailleurs depended entirely on the jockey pulley to lead the chain from sprocket to sprocket. Then, the makers discovered that a larger outer cage would help the chain to climb to the larger sprockets, much like a front derailleur cage. Notice how the outer cages of Campagnolo’s rear derailleurs have grown year by year from Nuovo Record to Super Record to C- Record.

Cable Length Adjuster

Some rear derailleurs provide a threaded sleeve where the casing enters the derailleur body. This allows you to set the angle of the shift lever. Other wise, you have to loosen the cable. Such an adjuster is required for indexed shifting. Campagnolo makes an accessory threaded sleeve that comes as part of the Syncro shift levers. Table 1 and 2 show which rear derailleurs have cable adjusters.

Lever Force

Every rear derailleur has a spring to pull the jockey pulley 6ack to the small sprocket. A strong spring requires more lever force to climb and more lever friction to prevent automatic shifting. It’s more pleasant to shift with a light lever pull. Shimano “Light Action” rear derailleurs have light springs.

To measure lever pull, I released the friction adjustment on the shift lever. Then I measured how much pull is needed at the end of the shift lever to climb onto the largest sprocket. This measures both the parallelogram spring force and the reluctance of the rear derailleur to shift onto the largest sprocket. Tables 1 and 2 show the required lever force.

Cable Travel

I used the calibrated shift lever as a caliper to measure the cable travel required to stroke the racing rear derailleurs over a narrow-spaced 7-speed freewheel and to stroke the touring derailleurs over a wide-spaced 6-speed freewheel. (Cable travel is shown.) There’s quite a variation. This gives you some idea of the problems involved in building your own indexed shifting system.

Jockey Pulley Travel

I used to measure the total travel of the jockey pulley with the limit stops all the way out. I don’t list this dimension anymore because all modern rear derailleurs have more than 1.65 inches of travel, which will handle a wide- spaced 7-speed freewheel.

Chain Wrap-Up

The derailleur design should position the jockey pulley high enough that the chain wraps around the sprocket for nearly 180 degrees. This is particularly important on the small sprockets. If there is less than, say, six teeth of wrap, the chain may jump forward when you stomp on the pedals, especially with worn chains or worn sprockets.

Moveable Jockey Pulley

The Huret Duopar provided the archetype for the moveable jockey pulley. In 1976, Huret invented and patented a rear derailleur with the jockey pulley mounted on a separate unsprung parallelogram. The jockey pulley on this derailleur floats freely up and down 1½ inches, which is the difference in radius between a 14-tooth and 34-tooth sprocket. The jockey pulley is just the right distance from the sprockets in every gear, so the Duopar shifts a bit early in every gear. SunTour and Shimano responded with their own moveable jockey pulley rear derailleurs, the MounTech and the Super Plate. They had to install a spring in the second parallelogram to get around Huret’s patent. Moveable jockey pulley derailleurs have extra pivots and extra parts so they’re inherently less rugged than conventional rear derailleurs. Mountain bikers want strong equipment, so the MounTech and the Super Plate were dropped. The Duopar is the only survivor of the genre.

Derailleur Capacity:

There are two rear derailleur capacity specifications: the largest freewheel sprocket that the derailleur can climb onto, and the total amount of chain that it can wind up. Tables 1 and 2 show these capacities.

Maximum Freewheel Sprocket:

Today’s derailleurs fall into two categories: racing and touring. The only mid-range derailleurs still available are low-end steel models. The top-of-the- line racing derailleurs can handle at least a 24-tooth maximum sprocket. The less expensive models can handle 28- or 30-tooth sprockets.

Today’s touring derailleurs can handle 32- or 34-tooth sprockets. However, most of today’s touring derailleurs need to be mounted on a touring hanger to handle a 34-tooth sprocket. If your bicycle has a racing dropout, you may have to restrict yourself to 30- or 32-tooth sprockets. The old wide-range touring derailleurs used to be able to handle 36- or 38-tooth sprockets.

There’s a sub-species of gear freaks who constantly seek lower Lows. (I don’t consider myself a member since I limit myself to a Low of 19 inches.) These people use SunTour’s 38-tooth alpine sprocket or they buy custom-made sprockets as large as 42-tooth. With the demise of Shimano’s Super Plate and SunTour’s AG, the Huret Duopar is the only surviving rear derailleur that can shift over these “buzz saw” sprockets.

Tables 1 and 2 show two maximum freewheel sprockets: the advertised size and the tested size. The makers underrate their capacities a little, partly in fear of the trial lawyers and partly to make sure that indexed shifting will work, even in the worst case. I tested the racing rear derailleurs with a narrow-spaced freewheel and a racing derailleur hanger with a 1-inch drop. I tested the touring rear derailleurs with a wide-spaced freewheel and a touring hanger with a 1.1- inch drop. They shifted well in both the friction and the indexed mode with the maximum sprocket shown.

Maximum Chain Wrap-Up Capacity

The wrap-up capacity is determined by the distance between the jockey pulley and the tension pulley. When the cage is fully extended, the chain must reach around the large chainwheel-large sprocket combination. When the cage is fully wound back, the chain shouldn’t hang loose in the small chainwheel small sprocket combination. Even if you never plan to use the large chainwheel-large sprocket gear, you must size your chain length to handle it. Otherwise, you could wreck your derailleur or worse with a missed shift.

You measure wrap-up capacity by adding the number of teeth on the largest chainwheel and the largest sprocket and subtracting the number of teeth on the smallest chainwheel and the smallest sprocket. Double-pivot derailleurs can often wrap up more chain than advertised. However, if you take advantage of this extra wrap-up capacity, they shift poorly.

I used to advise readers to exceed the advertised wrap-up capacities and I listed larger numbers based on my own tests. However, I don’t think that you can take much liberty with the advertised capacity of the current Shimano and SunTour rear derailleurs and still expect good indexed shifting.

There’s one exception. Triple-chainwheel bikes shouldn’t use the inner chainwheel with the small freewheel sprockets because the gears are duplicates and the chain may rub on the middle chainwheel. For triples, calculate the wrap-up by adding together the big chainwheel and the biggest sprocket, but subtract the small chainwheel and the smallest middle sprocket that you plan to use, rather than the smallest one on the freewheel. If you ever accidentally shift into one of the little-little combinations, the chain will hang loose, but it doesn’t matter.

Rigidity and Longevity

With rear derailleurs, as with most things, you get pretty much what you pay for. The more expensive rear derailleurs have better bearings for the pulleys and the parallelogram. The spring-loaded pivot(s) is sealed to keep out moisture. The parallelogram pivots use stainless steel pins and brass bushings. All of these features increase the rigidity of the derailleur and they lengthen the life until wear causes shifting to get sloppy. I inspected each of the derailleurs and my judgment of their rigidity and longevity is shown in tables 1 and 2.

Racing Rear Derailleurs

An ideal racing rear derailleur has the following characteristics:

• Quick positive shifting from one sprocket to the next, under load, with out hanging up or skipping the desired sprocket.

• Precise, predictable shifting response to lever movement.

• Light, uniform lever pressure when shifting.

• Enough chain wrapped around the sprockets to avoid chain jump under load in any gear.

• Capacity to shift over the largest sprocket normally used by racers (24 teeth).

• Ability to shift over narrow-spaced 7-speed freewheels.

• Rugged, reliable, long-wearing construction.

• Lightweight.

In selecting a racing rear derailleur you have two basic choices: conventional or indexed shifting.

Conventional Shifting

If you opt for conventional shifting, you can still use a Shimano or SunTour indexed shifting rear derailleur. That’s what I would buy. The indexed SunTours will shift much like the older models. The indexed Shimanos will shift early so that you’ll have to revise your shifting technique. However, most people who buy a conventional rear derailleur and friction shift levers in today’s market will be buying either a Campagnolo single-pivot derailleur or one of the clones from Galli, Mavic, Ofmega, and Zeus. These traditional derailleurs have won thousands of races. They’re rugged, reliable, and completely proven. They also shift imprecisely. Most racers grew up with Campagnolo Nuovo Records, learning to snap the lever too far and then pull back. Many racers think derailleurs are supposed to shift that way.

Indexed Shifting

If you opt for an indexed shifting racing derailleur, your choice is definitely between the various Shimano and SunTour models. The differences between them are subtle. The main difference is that Shimano gear trains always shift early, which makes Shimano more forgiving of wear or mis-adjustment. Also, Shimano has had two extra years of development to iron out the bugs. Campagnolo doesn’t expect many serious racers to opt for Syncro levers and I agree with them on that count.

Touring Rear Derailleurs

Touring rear derailleurs need all of the features of racing rear derailleurs. In addition, they have to shift over wide-range gearing, which might consist of a triple crankset with a total tooth difference of 24 teeth and a wide-range free- wheel with a 20-tooth difference between the sprockets. Touring derailleurs don’t need to be light or quick-shifting; they need to be rugged. As long as the wide-range market was a small fraction of the racing-sport touring market, touring rear derailleurs were step-children—simply conventional derailleurs with longer cages.

When the mountain bike appeared on the scene in the early 1980s, the builders used whatever touring, BMX, or motorcycle equipment worked best. I remember Gary Fisher giving me a wheel in exchange for a Huret Duopar and a Simplex front derailleur to be installed on mountain bike number five. I used to lay that you could do a mountain bike census by counting the total sales of SunTour thumb shifters and dividing by two. Touring components weren’t designed to be pedaled over branches and boulders or to shift under water.

SunTour and Shimano had the good sense to recognize a growing market. SunTour’s president, Junzo Kawai, attended the 1982 Pearl Pass Tour. The next year SunTour introduced MounTech, the first derailleur specifically designed for mountain bikes. From then on, SunTour and Shimano leap-frogged each other to provide the most rugged and best-shifting gear trains for the burgeoning mountain bike market. They sponsored teams and listened to feedback from the mountain bike builders. Wide-range mountain bike derailleurs became rugged, reliable, and able to shift under load.

By 1987, mountain bike rear derailleurs were so good that they could use Indexed shift levers. Huret and Simplex made belated attempts to catch the market, but so far, they’ve been competing with last year’s Japanese models. Campagnolo chose not to compete. Thus, it’s a choice between Shimano and SunTour when you upgrade the gear train on your touring bicycle. I think that Shimano is the clear favorite, though for 1988, SunTour has come out with significantly revised mountain bike rear derailleurs.

Rear Derailleur Makers

The business of making and selling rear derailleurs has become a shootout between Shimano, SunTour, and Campagnolo. Sachs-Huret is still competing but the clock is ticking.

Campagnolo

Either Valentino Campagnolo or Frank Berto is misjudging the future market for rear derailleurs. Campagnolo has never actively competed in the touring market and they’re completely out of mountain bikes. Their strength is the serious bicycle racer. They’re operating on the basis that serious racers don’t want indexed shifting. On the off chance that Campagnolo may have misread the market, they’ve produced the Syncro indexed shift lever for “noncompetitive cyclists.” Campagnolo’s rear derailleurs are only marginally suitable for indexed shifting.

Campagnolo’s model philosophy is unique. They never really make any thing obsolete. They keep old models in production as long as anyone will buy them. They introduce new models and let them compete with the old models to see what sells. I limited my tests to the four racing models that are widely distributed. I also tested the Victory LX, which is their latest touring rear derailleur.

The C-Record, introduced in 1985, is the ultimate single-pivot rear derailleur—strong, reliable, and handsome. It shifts better than any previous Campagnolo rear derailleur. However, the Nuovo Victory is the best Campagnolo rear derailleur because you can adjust the mounting angle. Both the C-Record and the Nuovo Victory require you to master the push-pull shifting technique. The Nuovo Triomphe lacks the angle adjustment, which is why it scores so much worse than the Nuovo Victory on a straight block freewheel.

The Super Record, introduced in 1982, is a minor upgrade of the Nuovo Record with slightly more capacity. Campagnolo has made small improvements over the years but current parts will still fit a 20-year-old model. I’ve tested the Nuovo Record four times since 1979. Compared to the competition, it has scored worse each time.

Today’s racers are using wider chainwheel differences, like 53/39, and smaller freewheel differences, like 12-20. This works against the old single- pivot rear derailleurs like the Nuovo Record and the Super Record. They shift much better with an 8-tooth difference on the front and a 14-tooth difference on the rear. I can’t think of any reason, except nostalgia, for buying a Nuovo Record or a Super Record rather than a Nuovo Victory.

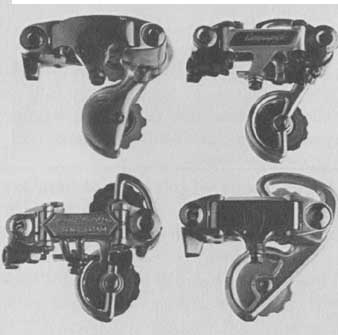

PHOTO 2 Campagnolo racing rear derailleurs: top left and right, C- Record

and Super Record; bottom left and right, Nuovo Record and Nuovo Victory.

If you measure the key dimensions of the Campagnolo Victory LX (or Leisure) touring rear derailleur, you’ll find that it’s a SunTour VGT without the slant parallelogram. It’s for the cyclist who wants to be tout Campagnolo and also wants a lower gear. The best thing that I can say about its shifting is that it’s better than Campagnolo’s previous touring rear derailleurs.

Huret

The 1983 marriage between Mile Huret and Herr Sachs gave birth to greatly improved derailleurs. The Sachs-Huret New Success, Rival, and Rider models are sturdy, good-shifting, double-pivot rear derailleurs. The Rival is the best-shifting, inexpensive, European rear derailleur. However, Huret suffers from limited distribution in the aftermarket. You rarely see a New Success or a Rival derailleur in a bicycle store or a mail-order catalog.

The rear derailleurs that you do see, the Jubilee and the Duopar, are from the period prior to Sachs-Huret. The Jubilee is an elegant, ultralight little jewel that shifts very nicely on narrow-range freewheels. It doesn’t have a whole lot of metal and it works best if you don’t abuse it. When it was introduced in 1976, the Duopar was unique—the only precise-shifting touring rear derailleur on the market, It’s a bit fragile, especially the titanium version. However, it shifts so well that it doesn’t need to be rugged. The market has changed and the competition has improved. The current steel model, called the Eco Duopar, is sturdier and has a loyal following.

ARIS, Huret’s entry into the indexed shifting derby, got a late start. I’ve only seen the prototype. Its success will probably depend on the ability of Peugeot, Motobecane, and Gitane to prove that French bicycles with French components have a future.

Shimano

Shimano has a two-year lead in the indexed shifting derby. Shimano’s top racing rear derailleurs are 7-speed Dura-Ace, Sante, 600 EX and 105. The top mountain bike or touring rear derailleurs are Deore XT and Deore. All six of these models are now found on the aftermarket as SIS models. Shimano also makes a range of L series (Light Action) and Z series rear derailleurs for the lower-priced OEM market. Not all of the L-series models and none of the Z series models are suitable for indexed shifting. Shimano changes models frequently but they keep the same names for a few years, so you can’t always identify the latest models. I show 1987 model numbers, which were the models that I tested. For 1988, Shimano replaced 600 EX with 600 Ultegra. They also introduced Exage, a new gruppo priced below the 105.

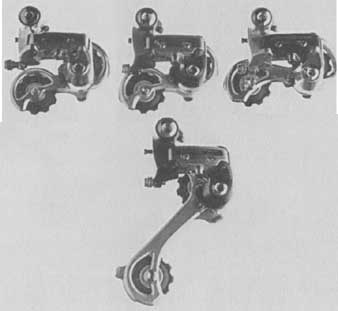

PHOTO 3 Huret rear derailleurs: top left and right, New Success and Jubilee;

bottom left and right, Rival and Eco Duopar.

The top-of-the-line models are all alloy and they have stainless steel pins and brass bushings for the parallelograms, sealed bearings in the pivots, and high-quality bearings in the pulleys. As you move down in price, some of the forged alloy parts become stamped alloy and then steel and the bearing quality goes down. The top models are long-lived.

All of Shimano’s current SIS derailleurs shift early. They’ve increased the tension of the top spring and changed the cage geometry to achieve this. Shimano uses words like “ballistic” and “aggressive” to describe shifting performance. What they mean is that the jockey pulley is very close to the sprockets in all gears. All shifts take place well before the jockey pulley gets to the next sprocket. When you use SIS rear derailleurs with friction levers, you have to forget your old shifting patterns. You push the lever till the shift takes place and then a bit more for good measure.

You can’t play games with advertised capacity any more. If you do, you may find that your jockey pulley rattles against the big sprocket, even with the angle adjustment screw turned all the way in.

The choice between Shimano and SunTour racing rear derailleurs is close, especially if you use friction levers. With indexed levers, SIS is a bit better. Deore and Deore XT are clearly better for loaded touring and mountain bikes, because SIS shifts better under load.

SunTour

SunTour’s top four indexed shifting racing rear derailleurs are Superbe Pro, Sprint 9000, Cyclone 7000, and Alpha 5000. The top three indexed mountain bike, or touring, rear derailleurs are XC-9000, XC-Sport 7000, and Alpha 5000-GX. The OEM models are SVX, Alpha 3000, Seven, and Honor. All of the old names like Superbe, Cyclone, Cyclone Mark II, LePree, AR-X, AR, MounTech, LeTech, and AG Tech are attached to old models. If you find them in a store or a catalog, they should be priced accordingly.

PHOTO 4 Shimano rear derailleurs: top left to right, Dura-Ace (racing),

Sante (racing), 600 EX (racing), 105 (racing); bottom left and right, Deore

XT (touring) and Deore (touring).

When SunTour upgraded their rear derailleurs for AccuShift, they added double-pivots, but they didn’t copy Shimano. Compared to Shimano, the top pivot spring isn’t as strong and the jockey pulley is closer to the cage pivot. There isn’t an angle adjustment screw, so you can’t match the mounting angle to the largest sprocket. As a result, the AccuShift rear derailleurs don’t shift as early as SIS rear derailleurs.

SunTour designed the AccuShift levers to match the AccuShift rear derailleurs. If you use an AccuShift rear derailleur with friction levers, it will feel very much like an old pre-index SunTour rear derailleur.

SunTour’s mountain bike rear derailleurs still have lots of capacity, especially in the friction mode. SunTour lists a larger maximum sprocket for friction shifting. If you want to stick with extra wide-range gearing, SunTour is a good choice.

For 1988, SunTour has significantly upgraded the performance of the mountain bike rear derailleurs.

Everybody Else

Everybody else now includes Simplex, and that’s rather sad. Lucieri Juy, the founder of Simplex, invented the double-pivot rear derailleur 50 years ago and Simplex has been a very innovative company. Unfortunately, Simplex fell into financial difficulties in 1985. French labor laws made it impossible to reduce their staff, so they went into bankruptcy. All of the disruption has limited their ability to develop an indexed shifting package. The reorganized Simplex is in the process of merging with Ofmega. Everybody else also includes Galli, Mavic, Ofmega, and Zeus. They all make Campagnolo-copy, single-pivot, racing rear derailleurs. It seems to me that if you’re going to put up with imprecise Campagnolo shifting, you ought to get the Campagnolo mystique.

PHOTO 5 SunTour rear derailleurs: top left to right, Superbe Pro (racing),

Sprint (racing), and Cyclone (racing); bottom, XC-9000 (touring).

Personal Favorite Rear Derailleurs

I had a 6-speed Shimano Dura-Ace/SIS rear derailleur on my Trek 2000 racing bicycle for more than a year and more than 2,000 miles. I set it up with a 28-tooth large sprocket rather than Shimano’s recommended 26. It was still shifting flawlessly, with very little tinkering or adjustment, when I replaced it with the 7-speed version. 1 can’t give a better recommendation than that.

I’m using a Shimano Deore XT rear derailleur on one of my touring bicycles, a Shimano Light Action on the second and a SunTour XC-9000 on the third. I use bar-end shift levers with all three, so I can’t talk about their indexed shifting. The XC-9000 and the Shimano Light Action handle 44 teeth of wrap-up, and 11-34 freewheels. The Deore XT handles 40 teeth of wrap-up and a 12—32 tooth freewheel. These capacities are way outside of the makers’ recommendations. All three derailleurs shift very well, under load, on a hill, but the two Shimano touring rear derailleurs shift better.