I have a guide about bicycles, published in 1935, that pictures a front derailleur—on a triple crankset, yet. The guide shows half a dozen rear derailleurs, so they must have been invented somewhat before that time. The inventor of the front derailleur was probably a strong-willed Frenchman. He certainly didn’t read the mechanical engineering textbooks, because they all say that the sprockets of a chain drive must be exactly aligned. Rear derailleurs also violate that rule, but at least they operate on the unloaded half of the chain. The front derailleur works on the loaded half of the chain, so front derailleurs have to use a cage instead of a jockey pulley to derail the chain.

A bicycle front derailleur is not only confronted with the challenge of a chain under load, it must also deal with the tooth differences between chainwheels, which are much greater than those between sprockets on a free- wheel. In short, a front derailleur poses a nasty design problem. Nevertheless, the inventor persisted and the first front derailleurs worked, after a fashion. The next models worked a bit better, and the next ones a bit better yet.

Current front derailleur models continue the evolutionary process, both by finesse and by brute force. I’ve been testing derailleurs for a decade and there’s clearly been substantial progress. The makers have learned that front derailleurs must be rigid. If the cage deflects under load, upshifts will be hesitant and unreliable. Similarly, there’s been a lot of ingenious metal bending applied to the cage contours to help seduce the chain from one chainwheel to the next.

There haven’t been any dramatic breakthroughs in front derailleur design similar to indexed shifting. However, the demands of mountain bikers have had a very salutory effect on wide-range front derailleur performance. My front derailleur tests for this section revealed major improvements in the newer models. If you’re struggling along with an old, worn-out front derailleur, be advised that the latest models shift much more pleasantly.

Today’s front derailleurs are designed for three specific gear trains: racing, half-step touring, and crossover touring. Buy the model that suits your gear train. If you do that, front derailleur selection isn’t a big deal anymore. Indeed, front derailleurs are often bought as an afterthought. You buy a fancy new rear derailleur and you take the front derailleur that matches it. Actually, that’s not a bad approach, since the same companies that make top-rated rear derailleurs also make top-rated front derailleurs. The indexed shifting shakeout that dramatically reduced the number of rear derailleurs on the market also reduced the number of front derailleurs.

Hurrah for that! I tested 81 different models for and each test took more than an hour. About half of those 1986 models are still available. However, I only show the best-performing 10 of them. I also tested 16 new front derailleurs from Shimano and SunTour for this section. They were measurably better than anything you could have bought two years ago.

Since there’s no standard definition of what constitutes a “racing” or a “touring” front derailleur, I developed my own. A touring derailleur should be able to handle a 52xXx28 triple crankset (the size of the middle chainwheel will vary according to the gearing system). Anything with less capacity than that is, by my definition, a racing derailleur. Note that the same front derailleurs are used for both racing and sport touring. In fact, most racing front derailleurs have enough capacity to handle a triple crankset. They just don’t shift as well as a purpose-built touring front derailleur. Similarly, a touring front derailleur would think that it had died and gone to heaven if you installed it on a racing crankset. Of course if you did that, your bald-legged racing buddies might sneer at you.

Racing Front Derailleurs

Racing is an easy derailleur service, since the chainwheel difference on a racing crankset is usually about 12 teeth. The standard racing crankset used to be 52/42. Today 53/39 is the closest thing to a standard. The 39-tooth inner chainwheel allows smaller big sprockets to be used on the freewheel. Every front derailleur shown in TABLE 1 will shift well on a 53/39 racing crankset. Racing front derailleurs have narrower cages to make sure that the chain doesn’t come off at a crucial time.

Over the past 20 years, racing front derailleurs have improved with each succeeding model. The Campagnolo Nuovo Record is the exception. It worked right when it was introduced in the late 1960s, so Campagnolo never fixed it. But the tide has come in around the Nuovo Record. Now it’s merely good in a field of very good and excellent front derailleurs.

TABLE 1. Racing Front Derailleurs. The overall quality rating is my best judgment, summing up alt of the factors evaluated. You don’t see any F or P ratings because all of the derailleurs that I’ve listed are pretty darn good.

Touring Front Derailleurs

It’s much harder to shift over a wide-range triple touring crankset than over a racing double crankset. Fortunately, today’s touring front derailleurs are five times better than their ten-year-old parents. Both mountain bikers and cross-country tourists can appreciate the improvements. The touring front derailleurs listed in TABLE 2 can reliably shift over any sensibly selected triple crankset that you care to use. The old books that advised you to shift before you reached the hill are as obsolete as the old front derailleurs that they described. With just a modest bit of technique, today’s front derailleurs will shift on a hill under load.

There are now two distinct types of touring front derailleurs, one for half- step gearing and the other for crossover gearing. (1 wrote about the difference between these two types of gearing in section 3.) First decide which type of gearing you prefer, then choose the front derailleur to match. Hall-step front derailleurs are for cranksets like 50/45/28. Crossover front derailleurs are for cranksets like 48/38/28. Crossover front derailleurs can’t be mounted correctly on cranksets with half-step chainwheels because the deep inner cage hits the middle chainwheel. A half-step front derailleur can be used on a crossover crankset, but it won’t shift as well as a good crossover front derailleur.

Crossover Front Derailleurs

Many people think that a “split-the-difference” crossover crankset like 52/40/28 is easier on the front derailleur than a 52/47/28 half-step, with a little step and a humongous one. Many people are wrong. In fact, a 52/28 double is easier on the front derailleur than a 52/40/28 triple.

== ==

TABLE 2. Touring Front Derailleurs; Make and Model. 1. See the text for a description of the crankset combinations used in the tests. The overall quality rating is my best judgment, summing up all of the factors evaluated. You don’t see any F or P ratings because all of the derailleurs that I’ve listed are pretty darn good.

== ==

Why is that, Doctor Derailleur?

After observing 10,000 or so front shifts, I finally figured it out (maybe I’m just a slow learner). The 28 to 40 upshift is poor because the front derailleur is mounted an inch too high for the 40-tooth chainwheel. If you remove the outer chainwheel, it becomes obvious. There’s your derailleur way up on the seat tube. The tail of the cage gently massages the chain about 3 inches behind the chainwheel. No wonder the upshift is so poor!

You have to force the upshift by pushing the chain way past the middle chainwheel. When it finally shifts, it may climb onto the middle chainwheel, or it may go farther over onto the outer chainwheel, or go even farther off into the wild blue yonder. The whole performance is accompanied by much grinding, chattering, and mechanical sadism. I used to say that the middle chainwheel was “hiding in the shadow” of the outer chainwheel. That’s true, but the real problem is the 12-tooth difference between the middle and the outer chainwheels, which forces you to mount the derailleur too high.

The way to make a 52/40/28 triple shift better is to convert it to a 48/40/28, or to a 52/44/28. You either lower the derailleur down to the middle chain- wheel, or raise the middle chainwheel up to the derailleur. Raising the little chainwheel doesn’t help at all. Yet many people decide that God intended them to walk their bikes up steep hills, so they convert to something silly like a 52/40/34.

Mountain bikes use crossover gearing. To meet the demand for bullet proof front derailleurs, the makers developed a new class of crossover super derailleurs. These new crossover derailleurs have an extra-deep inner cage that just clears the middle chainwheel. Given the magnitude of the task, they shift very well. However, you can overpower even the best of them by using a triple crankset with too much difference between the middle and the outer chainwheel. Ten teeth is a practical limit. With a 10-tooth difference, the front derailleur is mounted about an inch too high for the middle chainwheel. Go to a 12-tooth difference (say a 50/38/28 crankset) and the 28/38 upshift will be marginal.

Half-Step Front Derailleurs

I’m a wee bit biased toward half-step gear trains. I’ve been using half-step plus granny gearing for a decade. I didn’t invent the arrangement, but I named it. I think it’s the only way to set up triples for over-the-road use.

A half-step front derailleur has to have a shallow inner cage so that it doesn’t run into the middle chainwheel when you shift to the outer chainwheel. Even though mountain bikers outnumber loaded tourists about a zillion to one, Huret, Shimano, and SunTour (bless their hearts) still make pure half-step front derailleurs. SunTour’s crossover front derailleurs require only a six-tooth chainwheel difference. They can be mounted just a bit high and they’ll work on half-step cranksets. However, SunTour’s half-step front derailleur works better.

Shimano’s half-step looks just like their crossover, but the inner cage has a wide chamfer so that it clears the middle chainwheel. You can even use a racing front derailleur on a triple crankset if you’ll forgo using the granny chainwheel with the smallest cogs.

Front Derailleur Tests and Measurements

I tested front derailleurs for capacity, rigidity, and shifting performance. The capacity and rigidity tests were the same for racing, half-step, and cross over front derailleurs. I used different performance tests for the three different kinds of front derailleurs.

Capacity Measurements

The capacity measurements are simple geometry. I measured the various dimensions with a ruler or a vernier caliper. Some of the front derailleurs have appetites that are bigger than their stomachs. They can clear wider range cranksets than they can shift over. Tables 1 and 2 show five different capacity numbers.

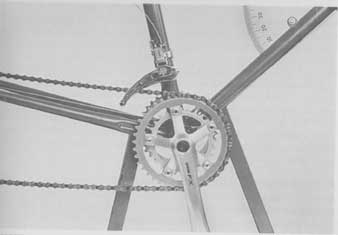

PHOTO 1 A 52/40/28 crankset with the outer chainwheel removed to show a

high- mounted front derailleur.

The capacities list the middle or inner chainwheels that go with a 52-tooth outer chainwheel. I used a 52-tooth outer chainwheel for all my measurements and tests. If you use a different outer chainwheel, just add or subtract the appropriate number of teeth from the middle and inner chainwheels listed in the tables. For example, TABLE 1 states that the Campagnolo C-Record shifts well on a 52/32 double crankset. If you’re using a 50-tooth outer chainwheel (2 teeth smaller), then the inner chainwheel can be a 30-tooth (also 2 teeth smaller). I could have shown a 20-tooth chainwheel difference, but I think that using actual chainwheel sizes is more straightforward.

If you are using Shimano Biopace or oval chainwheels, treat them like round chainwheels. If you are mixing oval and round chainwheels, add 2 teeth to the size of the oval chainwheel, because a 50-tooth Biopace has the same outer diameter as a 52-tooth round chainwheel.

Advertised Smallest Inner Chainwheel

The numbers in the “advertised” column are taken right from the catalogs. Each maker decides whether to list the mechanical capacity based on dimensions and clearances, or the shifting capacity based on some performance criteria.

Measured Smallest Inner Chainwheel (Double)

Based on my measurements, the “measured double” number identifies the smallest inner chainwheel that can be combined with a 52-tooth outer chainwheel without the chain rubbing on the spacer at the rear of the derailleur cage. For this measurement, I set the chain on the 14-tooth freewheel sprocket. If the spacer had a “step” in it, I positioned the derailleur for maximum chain clearance. This number depends a bit on chainstay length and seat tube angle. Note that this is a mechanical measurement, not the results of my shifting tests.

Measured Smallest Inner Chainwheel (Triple)

The “measured triple” numbers were obtained in the same way as the measured doubled numbers, but with the chain set on a 20-tooth middle freewheel sprocket. If you set up a triple crankset with the listed inner chainwheel and you tried to use that inner chainwheel with the smallest freewheel sprocket, the chain would rub on the back of the derailleur. By giving up 2 or 3 of your 15 (or 18) speeds, you can stretch the capacity of your front derailleur. On my Redcay, I use an old Dura Ace EX racing front derailleur with a 48/44/24 crankset and an 11—34 freewheel, but I only use the 24-tooth chainwheel with the 26- and 34-tooth freewheel sprockets.

Largest Middle Chainwheel

You need the information in the “largest middle chainwheel” column in order to buy a front derailleur for a half-step plus granny triple. The measurement is based on the depth of the derailleur’s inner cage. Racing front derailleurs have shallow inner cages that can pass over a 49-or 50-tooth middle chainwheel. Half-step front derailleurs can usually pass over a 48-tooth middle chainwheel. Crossover front derailleurs have deep inner cages. To use one on a half-step crankset, you have to mount it too high. Note that this is a maximum size. With a 49-tooth limit you can use a 52/48 half-step with no problem.

Smallest Outer Chainwheel

There’s a very modest trend towards smaller outer chainwheels. With 11-, 12-, or 13-tooth freewheel sprockets, you can get the high gear you need with smaller chainwheels. For example, a 41-tooth chainwheel and an 11-tooth sprocket gives the same High as a 52 and a 14.

The front derailleur is mounted lower with a smaller outer chainwheel. Mount it low enough and it will foul the rear derailleur cable. The number shown is the smallest outer chainwheel that lets the front derailleur clear a cable that runs 3/8 inch above the chainstay. If the rear derailleur cable runs under the chainstay, subtract six teeth from the listing.

Rigidity Testing

Rigid front derailleurs shift better than flexible models. That’s why worn- out front derailleurs with loose bushings shift so poorly. To test rigidity, I made a simple test jig with a dial gauge and a spring balance. I pull on the end of the cage, first with a one-pound force and then with a ten-pound force. The one- pound deflection is a rough measure of the slop in the derailleur’s mechanical construction. The ten-pound deflection measures the overall strength of the front derailleur’s cage and parallelogram. (I arrived at the ten-pound figure by multiplying a normal lever pull by the mechanical advantage of the shift lever and the front derailleur.) The results of both types of rigidity test are recorded in tables 1 and 2. More deflection indicates a flimsier front derailleur.

Shifting Performance of Front Derailleurs

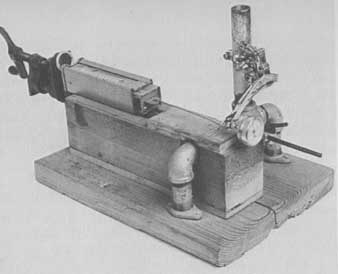

I measured front derailleur shifting performance with the same derailleur testing machine that I used for rear derailleurs. The machine is a bicycle frame with the crank driven by a gear motor. The shift levers have pointers so I can see where each shift takes place. (This machine is shown.) The shifting performance ratings shown in tables 1 and 2 are more than test results; they also serve as predictions of how the derailleurs will perform on the road. I consider these ratings to be the most important data recorded in these two tables.

PHOTO 2 The rigidity tester.

Racing Front Derailleurs The latest model racing front derailleurs have a curved bulge on the inner cage that lifts the chain from the small to the large chainwheel. This bulge makes a major improvement in shifting compared to the old-style, flat inner cages. This is the main reason that the Campagnolo Nuovo Record has seen its best days.

To test racing front derailleurs, I used a 52/36 crankset and a Shimano Narrow Uniglide chain. I carefully adjusted the derailleur height, the cage angle, and the travel stops. Then I started the machine with the crank turning at 60 rpm. With the chain on a middle freewheel sprocket, I made repeated up and down front shifts. First, I snapped the lever from one position to the next and then I slowly moved the lever and observed how the shifts took place. High- scoring derailleurs pop the chain right up onto the big chainwheel with no chattering or vibration, even when I move the lever quite slowly. Low-scoring derailleurs shift reluctantly with much vibration. On downshifts, high-scoring models shift with a light lever force and the chain drops cleanly onto the small chainwheel.

You might wonder why I tested racing front derailleurs with a 52/36 chainwheel combination. That’s a 16-tooth difference and racers rarely use more than a 12- or 14-tooth difference between the chainwheels. I tried testing with 52/42 chainwheels, but it was just too easy. Even the worst front derailleurs shifted so well that I couldn’t measure significant differences. The 52/36 crankset provided a severer test.

I’ve ridden with most of these derailleurs and confirmed that the tests correlate with over-the-road performance. I could feel the large differences, but not the small ones. Basically, all of the listed racing front derailleurs shift very competently. Cranksets like 52/42 or even 52/36 aren’t much of a challenge.

I also tested the racing front derailleurs with a 52/47/34 triple crankset. I don’t think much of the Low that you get with a 34-tooth granny gear, but many sport touring bikes use this kind of triple. Again, this wasn’t a severe test and all of the derailleurs handled it well. The upshift from the 34-tooth to the 47-tooth chainwheel was the hardest part. Narrow chains make the test a bit more severe, but the best derailleurs just pop the chain over. The triple crankset score is a composite of the two upshifts and the two downshifts.

I added up the results of the two tests and the rigidity measurements and developed an overall shifting performance rating. ( TABLE 1 shows separate ratings for the tests on double and triple cranksets.) Finally, I installed a series of double cranksets with ever smaller inner chainwheels and checked shifting performance. The wider the chainwheel difference, the worse the shift. TABLE 1 shows the widest range double crankset that still gave a reliable shift, a G score. The best front derailleurs handled a 52/32 crankset quite comfortably, and they’re “racing” derailleurs, mind you.

Touring Front Derailleurs The tests on touring front derailleurs were much more severe than the tests on racing front derailleurs. I used one set of double and triple chainwheels to test the half-step front derailleurs and a different set to test the crossover front derailleurs. Sugino provided me with five Aero Tour triple cranksets and a full complement of chainwheels to do these tests.

I tested the half-step front derailleurs with a 52/32 double and a 52/47/24 triple. I used five different cranksets to test the crossover front derailleurs: a 52/28 double and 52/44/28, 52/42/26, 52/40/26, and 52/38/24 triples. Each triple crankset was a more severe test than the previous one. The 52/38/24 was a real rock crusher. In my 1986 tests, none of the front derailleurs shifted well on that crankset. Some of them couldn’t shift at all from the 24 to the 38.

I was impressed with the performance of the new Shimano Deore and Deore XT alpine front derailleurs. They shifted competently on the 52/38/24 crankset, better than any previous front derailleur. Before the tests, I had been using a Deore XT with a 46/36/26 Biopace crankset and I’d attributed its smooth shifting to the Biopace chainrings. The SunTour XC-9000 and XC-Sport 7000 were improved over the previous models, but they weren’t quite up to Shimano’s performance. We’re seeing the benefits of Shimano’s and SunTour’s support of mountain bike racing. These are mountain bike derailleurs that also work splendidly on touring bikes.

In spite of the improvement in front derailleurs, there’s a lesson in my test experience. If you want to use crossover gearing, keep the difference between the middle and the outer chainwheels as small as you can.

The best crossover front derailleurs handled the 52/28 double quite comfortably. It’s easy to test front derailleurs on double cranksets. All I do is evaluate how well they upshift from the inner to the outer chainwheel. It’s much harder to rate front derailleurs on triple cranksets. The shifts onto the middle chainwheel are more difficult, both on the testing machine and on the road. I rated the following factors, in order of importance:

• Smooth upshifiting from the inner to the middle chainwheel, without the need to overshift too far and then re-center.

• Smooth downshifting from the outer to the middle chainwheel, without early or late shifting. Early shifts can let the chain ride on the middle chainwheel, making you nudge it over with another jog of the shift le ver. This is more severe with narrow chains. Late shifting requires you to re-center after you shift. Sometimes a late-shifting front derailleur kicks the chain all the way over onto the inner chainwheel.

• Smooth upshifiting from the middle to the outer chainwheel. This is an easy shift on a half-step crankset and a harder shift on a crossover crankset. If the derailleur overshifts at all, or if it has a wide cage, it’s harder to adjust properly on an older crankset with a narrow gap between the crankarm and the chainwheel.

• Reliable downshifting from the middle to the inner chainwheel. None of the derailleurs had any problem with this shift. I’ve concluded that if you have a problem with the chain dropping oft on the inside, your front derailleur is probably set up wrong.

I added up all of these factors and converted the sum into an overall shifting performance rating. (Table 2 shows separate ratings for double and triple cranksets.)

Other Measurements

I took a set of calipers to the front derailleurs and measured their key dimensions. I also measured how far they moved in and out. Finally, I measured how many rear shifts you can make without having to readjust the front derailleur. These measurements, along with a few others, are detailed below and listed in tables 1 and 2.

Weight

The listed weight is for a clamp-on model. Lighter isn’t better for front derailleurs. More rigid is better. That’s why the less expensive models sometimes shift better than their highly polished and lighter siblings. If the bearings are the same, the heavier models shift better. If the weight differs a bit from the advertised weight, it just means that my test front derailleur weighed a it more or less.

Cable Travel

I used to laboriously measure the amount of cable travel required to shift a front derailleur over a double and a triple crankset. I don’t bother to do this any more. All current front derailleurs take about 0.4 inch of cable movement to shift over a double and about 0.6 inch to shift over a triple. Rear derailleurs require more cable movement than front derailleurs. All shift levers provide at least an inch of cable movement. Basically, you can mix or match front derailleurs, rear derailleurs, and shift levers. Huret front derailleurs take a bit less lever movement than most and SunTours take a bit more. If the makers go to indexed shifting for triple cranksets, cable travel will become an important measurement.

Rear Shifts with No Readjustment

This tells you how many shifts you can make with the rear derailleur before the chain moves over far enough to rub against the cage of the front derailleur. This depends mostly on the cage width at the rear, which is also listed. Wide cages let you make five or six rear shifts. Narrow cages limit you to only three shifts before you have to readjust the front derailleur. This is an approximate number because chain rubbing also depends on chain width, chainstay length, and the size of the chainwheel.

Racing front derailleurs have narrower cages because there’s less chance of the chain coming off the chainwheel with a narrow cage. Shimano and SunTour touring derailleur cages are quite wide at the rear. Most of them can shift over a six-cog, wide-spaced freewheel without adjusting the front derailleur. You can’t set up these wide cages properly with old cranksets that have a narrow gap between the crankarm and the outer chainwheel. Don’t blame the front derailleur if it shifts poorly because it’s misaligned.

Derailleur Cage Width

I measured the width at the rear of the cage and at the middle, opposite the seat tube. I talked about the rear width above. The cage width at the middle varies very little between derailleurs. Cage width was easy to measure on the old derailleurs with flat cages. It’s harder to measure on the current models because the cages now have all kinds of grooves and bulges to help the shifting. Some people bend the front part of the cage to improve downshifting from the big chainwheel. I leave it alone.

Cage Length

This is the distance from the centerline of the down tube to the rear cage spacer measured along the cage. Long-cage derailleurs can mechanically span larger chainwheel differences. This is the key difference be tween touring and racing derailleurs.

Cage Travel (Minimum)

This is the distance between the inner derailleur cage and the seat tube with the adjustment screw backed all the way out. For a normal double chainwheel, 0.80 inch gives lots of clearance. For a triple with a triple spindle, 0.70 inch will suffice. When you install a triple crankset on a double spindle, the inner chainwheel will be right against the chainstay. This requires 0.60 inch of clearance. Wide-cage derailleurs require a bit less clearance than those with narrow cages. If your front derailleur doesn’t have quite enough adjustment to drop the chain onto the inner chainwheel, you can sometimes do a bit of judicious persuasion with a file.

Cage Travel (Maximum)

This is the maximum distance between the seat tube and the inner cage with the adjustment screw all the way out. Triple chainwheels on triple spindles need 1.25 inches. If you find your derailleur won’t shift out far enough, it probably means you have a bad combination of spindles and cranksets, one which locates your chainwheels too far out. Both of the cage travel dimensions concern only triple cranksets.

Cable Attachment

Many lower-priced bicycles have a casing stopper on the down tube rather than a cable guide on the bottom bracket. These bicycles require a front derailleur with a casing stopper. Some derailleurs can handle both a bare cable or a casing. In tables 8-1 and 8-2, models that can handle a bare cable are identified by “cable” and those that can handle either a bare cable or casing are identified by “both.”

Front Derailleur Mounting

Most top-of-the-line racing front derailleurs are available in braze-on or clamp-on versions. There isn’t an industry standard for the braze-on mounting. The Shimano and SunTour fittings are similar to Campagnolo and their braze- on front derailleurs will mount on the Campagnolo fitting. Both my Trek 2000 and my Redcay sport touring bicycles have braze-on fittings. It’s prettier and there’s no clamp to scratch the paint.

However, there are disadvantages to the braze-on method of mounting. There’s limited vertical adjustment, so you have to pick your chainwheel size range and tell the builder before he brazes on the fitting. Since there’s no standardization in braze-on height, don’t expect to switch derailleurs once you select a braze-on model. When I had my Columbine made to order, I didn’t order a braze-on.

You can’t get the best shifting from your front derailleur unless it’s properly mounted. Generally speaking, I mount the front derailleur so that its outer cage is just high enough to clear the outer chainwheel. With half-step cranksets, I mount it so that the inner cage just clears the middle chainwheel. In either case, I allow only 1/16 inch of clearance.

The next part is trickier. All of the instruction sheets tell you to mount the derailleur so that the cage is parallel to the chainwheels. Fine, but which side of the cage? The inner and the outer cages aren’t parallel, since most derailleurs are wider at the rear. With the inner cage parallel, upshifting will be better. With the outer cage parallel, downshifting will be better. I tend to mount the inner cage a bit nearer to parallel, because upshifts are harder. This angles the derailleur out a bit. With many cranksets, you can’t go very far because the heel of the cage will hit the inside of the crankarm. This is a particular problem with TA Cyclotourist cranksets, which have a rather narrow gap. You have to fiddle with the angle adjustment, because the angle changes as you tighten the clamp. It’s a bit like adjusting a crank spindle.

Front Derailleur Makers

There’s a shakeout taking place in the business as described in section 7. The surviving companies are making fewer and better models. What follows is a brief overview of the major makers of front derailleurs and their current line of products.

Campagnolo

I talked about Campagnolo’s model names in section 7. There’s a front derailleur to go with each of the rear derailleurs. The new Campagnolo C- Record, Victory, Triomphe, and 980 front derailleurs share an improved cage design that shifts much better than the older cage on the Nuovo Record and Super Record front derailleurs. These two old front derailleurs must hold the record for unchanged design; they’re both old enough to vote. The two little pieces of black-anodized aluminum in the parallelogram of the Super Record cost an extra ten bucks. (Don’t say Mrs. Campagnolo raised any dumb children.) Campagnolo makes just one touring front derailleur, the Victory LX. It’s shifting performance isn’t up to the competition and its deep inner cage isn’t suitable for half-step cranksets.

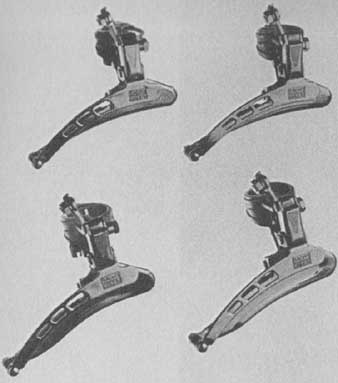

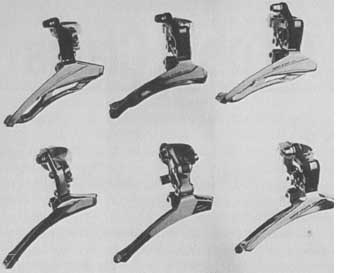

PHOTO 3 Campagnolo front derailleurs: top left and right, C-Record and Nuovo

Record! Super Record; bottom left and right, Nuovo Victory/ Nuovo Triomphe

and Victoty LX.

Huret

Huret’s New Success, Rival, and Duopar front derailleurs were introduced in 1985. They were a major improvement over the old models. So far, distribution in the aftermarket is limited. Huret shows racing, half-step touring, and crossover touring front derailleurs in their catalog. I’ve tested a dozen Huret front derailleurs, but I just show the five models that have the best availability. The Huret Jubilee is the lightest front derailleur made but it’s more for time trial records than for serious racers. It’s an old Huret design. The old Hurets had long, skinny cages and flexible parallelograms. They would chatter and vibrate and refuse to shift, especially after they wore a bit. If you have an old Huret front derailleur on your bicycle, any modern front derailleur will be a major improvement.

PHOTO 4 Huret front derailleurs: top left and right, New Success (racing)

and Rival (racing); bottom left and right, New Success (half-step touring)

and Duopar (crossover touring).

Shimano

Shimano introduces about four new front derailleurs every year so they’ve improved their products by evolution. The Dura-Ace is light and beautifully sculptured. The inner cage has an embossed ridge to aid upshifts. The 600 EX has more capacity than the Dura-Ace and it shifts nearly as well. The Sante and 105 are new models with the parallelogram slanted forward. The cage moves forward as it moves out. They shifted smoothly on a 52/32 crankset, six teeth wider than Shimano’s rating.

Shimano makes both half-step and crossover models for mountain bikers and tourists. They are the best shifting available. All Shimano front derailleurs have wide rear cages so you can shift over five- or six-sprocket freewheels without readjusting the front derailleurs. The only weakness of Shimano front derailleurs is that they will occasionally drop narrow chains off the inside or the outside. I think that this is caused by a cage width that’s designed for wide rather than narrow chains. Now that Shimano is promoting the Narrow Uniglide chain, I expect to see their cage widths become a bit narrower.

I used to limit the top scores of front derailleurs because even the best of them didn’t shift well compared to rear derailleurs. The Sante, 105, Deore XT, and Deore front derailleurs deserve their excellent score.

SunTour

SunTour, like Campagnolo and Shimano, reissues old names on new derailleurs. Most of SunTour’s front derailleurs were brand new in 1987 to match their new indexed shifting rear derailleurs. The racing front derailleurs are Superbe Pro, Sprint 9000, Cyclone 7000, and Alpha 5000. SunTour and Shimano racing front derailleurs look alike. They also shift alike, which is definitely top-notch.

SunTour’s mountain bike or touring front derailleurs are XC-9000, XC-Sport 7000 and Alpha 5000. They shift better than anything SunTour has made previously. The half-step models (called GT) shift as well as the Shimano Deore half steps. The crossover models (called OX) weren’t quite up to Shimano’s standard.

Some old SunTour front derailleurs have reverse lever movement. On most derailleurs, pulling back on the lever causes a shift up onto the big chainwheel. On the old SunTours, pulling back drops the chain onto the little chainwheel.

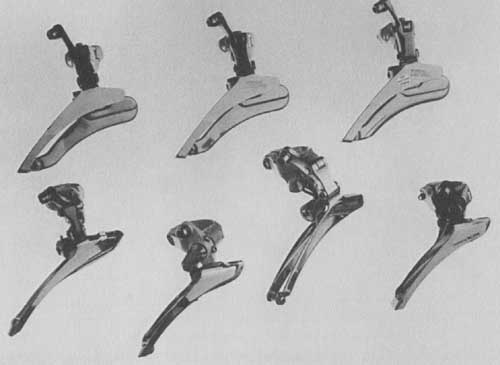

PHOTO 5 Shimano front derailleurs: top left to right, Deore XT (crossover

touring), Deore (crossover touring), and Deore (half-step touring); bottom

left to right, Dura-Ace (racing), Sante (racing), 600 EX (racing), and 105

(racing).

Once you get used to it, the reverse action makes a lot of sense. Both levers produce the same shift response. Many tandem riders prefer the “backwards” SunTours because they shift down onto the little chainwheel more positively. In 1987, SunTour surrendered to the common practice. All SunTour front derailleurs except the lowest-priced Spirit now have normal lever response.

Everybody Else

Everybody else is the same for both front and rear derailleurs. Galli, Ofmega, and Zeus make copies of the Campagnolo Nuovo Record front derailleurs to match their Campy-copy rear derailleurs. Simplex used to make excel lent front derailleurs, but they’re now almost out of business. Mavic makes a powerful and well-built racing front derailleur.

PHOTO 6 SunTour front derailleurs: top left to right, XC-9000 (crossover

touring), XC-Sport 7000-GT (half-step touring), and XC-Sport 7000-GX (crossover

touring); bottom left to right, Superbe Pro (racing), Sprint 9000 (racing),

and Cyclone 7000 (racing).

Best “Classic” Front Derailleurs?

For the past few years, it’s been a toss-up between Shimano and SunTour front derailleurs. The SunTours were usually slightly better shifting but I often mounted a Shimano to match the rear derailleur. Currently, I have a Dura-Ace and a Sante on the two racing bikes. I have a Deore XT crossover on one touring bike. The other touring bike has a braze-on front mount and I use an old model Dura-Ace racing derailleur. The commute bike serves as a test bed for whatever I’m currently playing with.