Tires don’t last forever, so each time a tire wears out you can buy a better one, and you’ve got lots of tires to choose from. There are two basic kinds of clincher bicycle tires: skinwalls and gumwalls. You can improve the performance of your bicycle by upgrading from a gumwall to a skinwall tire that matches your riding style.

To select the optimum skinwall, you have to select the right size and the right construction. This involves a compromise between lively performance on the one hand and durability and mileage on the other. Skinwall tires come in five sizes and four different constructions. The important thing is to pick the right size and the right kind of tire for you.

Terminology time. There are two classes of bicycle tires: tubulars and clinchers. Tubular or sew-up tires have the inner tube sewn inside the tire. Tubular tires are glued onto tubular rims. That’s fairly straightforward. But, when we turn to clinchers, things get trickier. A little historical background is needed to help sort things out.

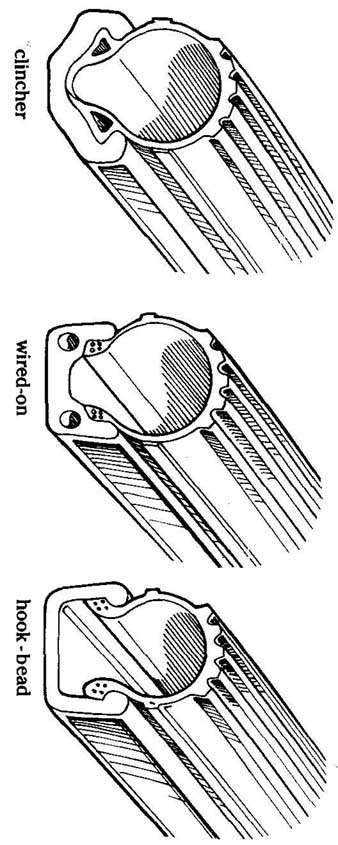

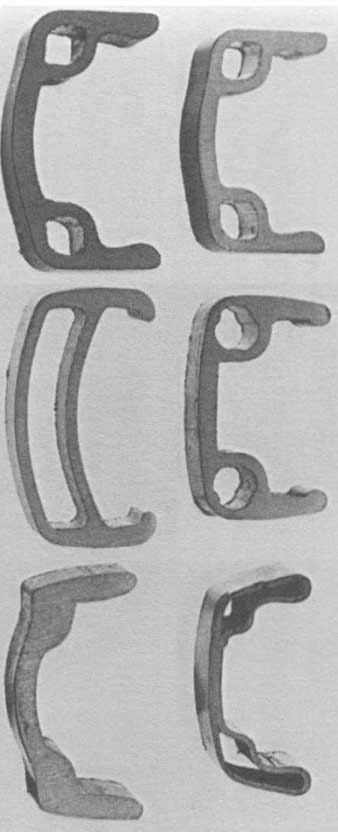

When Doctor Dunlop invented the pneumatic tire more than a century ago, he invented a tubular and tubulars were just as troublesome in those days as they are today. The inventors immediately set to work to develop a more reliable tire that was easier to repair. By 1896, there were three broad classes: tubular, wired-on, and clincher. The tubular tires of that time were just as they are today. The wired-on tires had strong wire beads that held them onto the rims, and clincher tires had two flaps that folded under the tube and bulges in the tire sidewall that fitted into grooves in the rim. It’s almost the same situation today except that there’s a whole lot of history and terminology that tends to confuse things. Today, everyone calls non-tubular tires “clinchers,” regardless of how they’re retained on the rim. (Bicycling once launched a campaign to refine the terminology but we lost.) Today’s clincher tires are designed for two basic kinds of rims: straight-side and hooked-edge. Tires designed for straight-side rims are called “wired-on” tires by the experts. The tire bead mates with the bead seat of the rim to keep the tire from blowing off. Tires designed for straight-side rims have steel beads. Tires designed for hooked-edge rims are called “hook-bead” tires by the experts. Hook-bead tires are a bit like the ancient clincher tires. The hook-bead is forced under the rim’s hooked-edge by the air pressure. This retains the tire securely at high inflation pressures. Tires with Kevlar beads must use hooked- edge rims. (See FIG. 1 for a depiction of clincher, wired-on, and hook-bead tires.)

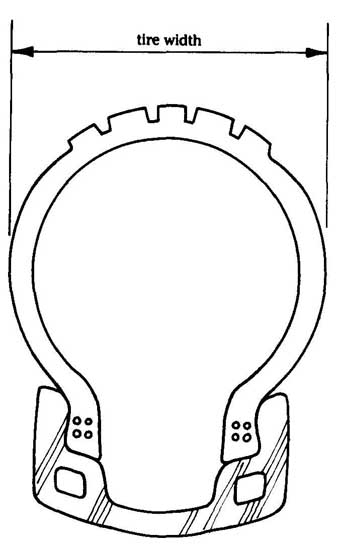

Tires are donuts and they have two diameters. The big outside diameter is what is usually termed the tire diameter and the little diameter is the tire width.

___ Tire Sizes and Tire Marking ___

While we’ve taken time out for terminology, we’d better talk about the strange numbers that designate tire sizes. There are three basic sets of numbers: ancient English, ancient French, and ISO-ETRTO (International Standards Organization-European Tire and Rim Technical Organization). The first two go back to the turn of the century and were based on the outside diameter of the tire. (Probably because that’s how buggies with solid rubber tires were sold.)

__ Ancient English System ___

The tire size 27 X 1 1/4 is an ancient English designation. Eighty years ago, the tire outside diameter was 27 inches, the tire width was 1.25 inches, and the rim outside diameter was 24½ inches. The English system covered both tires and rims. Thus, a 27 x 1½ tire required a smaller-diameter rim (24-inch) to provide the same 27-inch outside tire diameter.

Alter a while, certain rim sizes became national favorites. When the tire maker produced a 1-inch-wide tire to fit the standard 27 X 1.25 rim, it was labeled 27 X 1 1/4 X 1. You still see the dual designation occasionally, but today most makers call the tire 27 X 1.

There’s another little subtlety. A tire designed for a straight-side rim with a bead seat is supposed to be marked in fractions, say 26 x 1 3/8. A tire designed for a hooked-edge rim without a bead seat is supposed to be decimal marked, say 26 X 1.375. But, in the 27-inch and 700C sizes, hooked-edge rims have both hooked edges and bead seats so the tires don’t have decimal markings.

__ Ancient French System __

The tire size 700 X 39C is an ancient French designation. Eighty years ago, the tire outside diameter was 700mm, the tire width was 39mm, and the rim diameter was 622mm. The C was a code number that defined the tire width:

700A tires were narrowest (1 /8 inches), 700B tires were wider (1½ inches), and 700C tires were widest (1¾ inches). Today, in France 700A and 700B rims are still used. With an outside diameter system, they have larger bead seat diameters than 700C.

Today, at least in the USA, the C in 700C says in effect, “Stop all of this nonsense! This rim has a 622mm bead seat diameter. Period.”

__ ISO-ETRTO System __

The object of tire and rim marking is to ensure that a standard-sized tire fits a standard-sized rim. This means that the inside diameter of the tire has to be just a tiny bit larger than the bead seat diameter of the rim. The ISO-ETRTO size I’ designation is based on bead seat diameters, not outside diameters. This is clearly a better system, which is why the ETRTO designation has become an ISO standard. If everyone provided accurate ISO-ETRTO markings, we would be in clover.

Here’s how the system works. The ISO-ETRTO marking for a 27 X 1¼ tire is “32-630.” The first number, 32, specifies the section width in millimeters. The second number, 630, is the diameter in millimeters of the bead of the tire or the bead seat of the rim. All widths of 27-inch rims have a bead seat diameter of 630mm. All widths of 700C rims have a bead seat diameter of 622mm. Now you see why narrow rims designed for 27 X 1 tires are labeled 27 X 1 1/4. The ISO ETRTO number is often embossed on the tire tread rather than printed on the label.

FIG. 1 Three kinds of tires and rims.

FIG. 3 Measured width of a mounted tire.

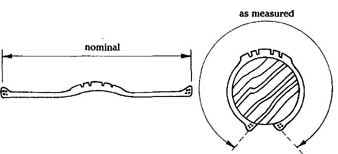

Section width is ISO-ETRTO’s method of measuring tire width regardless of what width rim is used. The section width is the width of the tire measured over the tread, divided by 2.5. To measure section width, you wrap the tire around a dowel and measure the width from bead to bead around the outside (see FIG. 2). The 2.5 converts tire circumference to tire diameter. You don’t divide by P1(3.14) because a clincher tire isn’t a complete circle; there’s a gap between the beads for the rim. If a tire is mounted on the correct rim, the section width and the measured tire width (FIG. 3) are nearly the same.

In theory, a tire labeled 27 X 1 has a section width and a mounted width of 1 inch (25.4mm), while a tire labeled 700 X 25C tire has a section width and a mounted width of 25mm. In practice, all three systems are very loosely interpreted and there’s considerable imaginative labeling. This does you a disservice, because the labeled size doesn’t have a standard meaning between brands or even within the same brand.

FIG. 2 ISO-ETRTO section width.

___ Clinchers versus Tubulars ___

If you add the total weight of tire, tube, and rim, you’ll always get more strength and performance per pound from tubulars. I suspect that this will continue to be true in spite of any future improvements in clincher tire or clincher rim design. The clincher rim is the real problem. It always weighs more than a tubular rim of equal strength. Bicycle racers put up with the disadvantages of tubulars because pound for pound, tubulars perform better than clinchers.

However, tubulars have a potful of disadvantages. First, they’re very expensive, especially the handmade silk tubulars that the old books rave about. Second, the tread isn’t very thick so they puncture easily. Third, it’s difficult to repair the punctures. Sometimes, you can find a pro bike store that has an old racer who will repair tubulars on his kitchen table for, say, $20 a pop. (That’s a as measured pun, son.) The normal choice is to repair them yourself or throw them away. Unfortunately, fixing tubulars is not a satisfying job like building wheels. Finally, you have to glue the stupid things back onto the rims, which is another messy, time-consuming task.

All of the old bicycle books wax ecstatic about tubulars. The key point to remember is that they were comparing old handmade silk tubulars to old clinchers, and clinchers have improved dramatically since those books were written. I haven’t rated tubulars since they represent such a small share of the market.

_ Rim Size Selection

When you buy a new set of wheels, or a new bicycle, you have to choose between two rim sizes: 27-inch (630mm bead seat diameter), or 700C (622mm bead seat diameter). Once you’ve bought the wheels, you buy tires to match the rims. The 8mm (0.3-inch) difference between the two sizes is so small that they perform exactly the same. It’s one more maddening bit of non-standardization. If you’re buying a new set of wheels, think about the following factors.

___ Switching between Tire Types___

All tubulars use 700C tubular rims. If you have 700C clincher rims, then you can switch wheels without having to move the brake pads. This used to be the main reason for picking 700C clinchers, but it’s less of a reason today because so few people use tubulars.

___ Tire Availability ___

Most high-class racing and sport touring bikes now come with 700C clincher rims. The tire makers have responded accordingly. The narrowest, best-performing, lightest clincher tires are generally available only in 700 X 19C or 700 x 20C sizes. The makers don’t produce the companion 27 X size, or, if it’s available, you have to special order it. The opposite thing has happened with fat touring tires. The tourist wants to be able to buy a replacement tire in Lodgepole, Montana, so he usually selects 27-inch tires. Not all tire makers offer the companion 700 X 32C tire to go with the 27 X 1¼, or the 700 x 35C tire to go with the 27 X 1%.

Plan accordingly. If you’re going to use narrow, ultra-light clincher tires, buy narrow 700C hooked-edge rims on your new wheels. If you plan to use fat touring tires, buy wide 27-inch hooked-edge rims. If you plan to tour in Europe or Bangladesh, check the local preference. The closest thing to an international tire size is 650A.

___ Fender Clearance and Brake Reach ___

When you buy a new set of wheels for your present bicycle; you can sometimes correct the original maker’s lack of prescience. For example, few bicycles designed for the U.S. market have adequate fender clearance, especially with fat touring tires. You’d like to have about ¾ inch between the outside of the tire and the inside of the fender. If you want to ride in the rain but your bi cycle doesn’t have enough clearance for fenders, switching from 27-inch to 700C wheels will give you an extra Vs inch.

If your old bicycle used centerpull brakes and you want to install one of today’s fancy short-reach sidepull brakes, you may find that the brake mounting hole is a bit far from the rim. If the bike also used 700C wheels, then switching to 27-inch wheels will move the rim a bit closer to the brakes.

__ Tire Performance __

When selecting a set of clinchers, you have to make two decisions. The easy choice is between cheap, poor gumwalls or expensive, good- performing skinwalls. The sidewall of a gumwall is Vs cord and Vs rubber. In a skinwall, the proportions are reversed. Flexing all that rubber makes thick gumwall tires harder to pedal.

Your second choice between fat clinchers and skinny clinchers is harder. You have to decide if you want wider, lower-pressure tires and tubes that feel sluggish and are heavier, softer riding, harder pedaling, longer wearing, and more puncture-resistant. Or do you want narrower, higher-pressure tires and tubes that are lively, lighter, harder riding, easier pedaling, shorter wearing, and more puncture-prone? Note that each advantage has a companion disadvantage. In bicycle tires, there’s no free ride. (Pun intended.)

There is, however, still a lot of mystique in bicycle tire advertising. Yester day’s snake oil peddlers now sell bicycle tires. They’d have you believe that there’s a magic combination of rubber compound, tread, and sidewall design that will roll uphill without pedaling.

Before writing this section, I talked to the tire experts at Avocet, CyclePro, Michelin, and Specialized. I took their expert advice and integrated it with my own experience. I tried to pick out the important differences between tires. Then, I obtained a pair of each of the more than 50 widely distributed, top-of- the-line clincher tires, weighed them, and measured their key dimensions.

Finally, I prepared Table 1, which shows the significant differences between tires. You can see the advantages along with the disadvantages and pick features that are important to you.

Let’s look at the major differences in tires, in order of importance.

__ Tire Size __

There are five nominal English sizes, each with a companion nominal French size as shown in Table 2 on page 240. Neither the English, French, nor ISO-ETRTO markings indicate the actual tire section width or the actual tire width when mounted on a proper rim. In the narrowest size, tires are larger than the labels. In the wider sizes, tires are smaller than the labels. Each maker exaggerates in a different way. It’s as if there’s a Tire Labeling Politburo with a rule that the label must not tell the truth.

Avocet’s labels are closest to the truth. Michelin makes three tires that have a section width of 25mm. Because of the Politburo, they can’t be labeled 700 X 25C. So Michelin labeled the Hi-Lite Road and Hi-Lite Comp 700 X 23C and the Select 700 X 28C. Actually, the mislabeling has gone on for so long that now you expect a 1 Vs tire to be about 1-inch-wide and a properly labeled tire would be hard to sell.

I used the French sizes for my measurements. I also show the companion English size in tables 1 and 2. Each English size tire is exactly the same width as its companion French size tire. They’re 1 percent larger in circumference and they weigh 1 percent more. Table 1 shows the labeled ISO-ETRTO section widths, where the makers show this dimension. It also shows the actual ISO-ETRTO section width based on my measurements.

I mounted all 50 tires, inflated them to the listed pressure, and measured the mounted width at four places. The narrow tires (1 1/8” or 28mm and smaller) were mounted on 14mm, narrow rims. The wide tires (1¼ or 32mm and larger) were mounted on 16mm, medium-width rims. Table 1 shows the mounted tire widths. Use these actual mounted widths rather than the labeled size when you want to switch to a comparable tire of a different brand.

_ Inflation Pressure _

Inflation pressure is the other significant variable. You can make a major change in the feel and performance of any tire by carrying ten psi more or less than the recommended inflation pressure. Table 1 shows the inflation pres sure marked on the sidewall of each tire. When properly installed on the correct rim, tires are supposed to withstand twice their marked inflation pressure without blowing off the rim. And, as a matter of fact, most tires are strong enough to withstand such pressure, but keeping the tire on the rim is a different matter. If you install a maximum tolerance tire on a minimum tolerance rim and overinflate it, it may just blow off.

In the process of installing the 50 tires on rims to measure them, 3 tires came off the rims at less than the rated inflation pressure because I didn’t make sure that the beads were properly seated. Hooked-edge rims are much better at preventing blow-off than straight-side rims. Straight-side rims are really only suitable for casual riding at pressures less than, say, 85 psi. If you’re going to overinflate your tires, read the instructions about seating the beads and be careful. There’s a lot of energy stored in that compressed air.

The stress in the casing of a tire goes up directly with tire diameter and with inflation pressure. A 1½-inch-wide tire at 75 psi has the same casing stress as a ¾-inch-wide tire at 150 psi. There’s a bit of a Detroit horsepower war going on with inflation pressures. Tire buyers believe higher pressure ratings are better. Some tires now show a recommended pressure and a maximum pres sure. This reflects the fact that the blow-off pressure is higher with hooked- edge rims, so the maximum pressure can be higher.

I used to think that the pressure listed on the sidewall was the maker’s recommendation for heavy riders. From my conversations with the makers, I’ve now concluded that they don’t have a magic formula that says this inflation pressure gives the best possible performance for some given rider weight. Their pressure ratings are based on casing stress, blow-off pressure, and legal liability considerations.

Experiment a bit with inflation pressure. Heavy riders on narrow tires should try an extra ten psi, especially on the rear tire. Both overinflation and underinflation cause tires to wear out prematurely. It’s essential to keep a narrow 27 X 1 or 700 X 20C tire fully inflated or you’ll get a “snakebite” puncture when your rim bottoms out going over potholes or bumps. The tube is trapped by the folded tire between the rim and the bump. The tube is folded, which is why there are two holes ¼ inch apart. Snakebite punctures tell you that your tire pressure is too low, your tire diameter is too small, or your waist diameter is too large.

This sounds like all you need is a good high-pressure tire pump and lots of pressure. Unfortunately, overinflated tires aren’t much fun either. The ride beats you up like a jackhammer and they “feel” insecure when you corner. If you’re a lightweight and your tires feel too harsh, try lowering the pressure ten psi. The ride will be more comfortable and the bicycle will corner better.

You need an accurate pressure gauge to find your optimum inflation pres sure. I wrote an article on pressure gauges in the May 1987 issue of Bicycling. I concluded that the hand-held Kingsbridge and Meiser pressure gauges were accurate and that the gauges that are installed on pumps take a beating with time and tend to read high.

Tire size ties in with inflation pressure. Narrow tires can withstand higher inflation pressures than wide tires. Over a narrow range, you can match the tire size to the rider weight and the road surface by raising or lowering the inflation pressure. At some point, the heavy rider finds that he has to grossly overinflate a narrow tire. He needs a wider tire. Similarly, the light rider doesn’t get much comfort from lowering the pressure more than say ten psi. He needs a narrower, lighter tire.

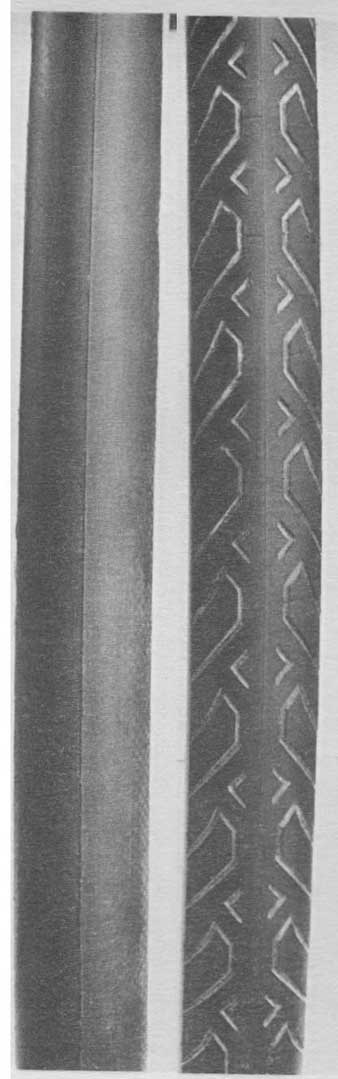

PHOTO 1 Tire labeling problems: top, Michelin 700 x 28C Select (actual width,

23mm); bottom, Michelin 700 X 23C Hi-Lite Comp (actual width, 23.5mm).

I’ve tried just about every narrow, high-pressure, high-performance, clincher tire made, starting with the Michelin Elan in 1975. I’ve had hundreds of flats. Literally, because I’m working on my third box of 100 Rema patches. To me the message is very clear. At 180 pounds, the smallest tire that I should use is 27 X 1 1/8 (or 700 x 28C). However, like Charlie Brown trusting Lucy to hold the football, I want to believe the snake oil salesmen. There’s no doubt that my 24-pound Trek 2000 with 27 X 1 (or even 700 X 19C) tires at 125 psi is a joy to pedal. I can repair a rear flat and be moving in less than ten minutes and I always carry a spare tire and tube when I’m playing lightweight tire games.

I’ve learned something from all of this. I get a different kind of fun riding properly-sized or even oversized tires. On my long distance tours, I use 27 X 1 /s (or 700 x 35C) tires and I’ve learned to love them. I leave the Michelin Hi-Lite Tours inflated to 80 psi on the Columbine touring bike all year round. They’re easy riding, insensitive to road surface, and they almost never get a flat. It’s reassuring to know that I can run off the shoulder of the road onto the gravel and nothing happens. On city streets, wide tires shrug off paving grooves and ridges that would dump you on narrow tires.

The wide tires seem to be about 10 percent harder to pedal. It takes me about 15 minutes longer to do the same 33-mile ride on the Columbine than on the Trek. I keep reminding myself that at 15 mph, 70 percent of my power input is spent overcoming wind resistance and that the wind resistance goes up as the cube of the speed. Going down steep hills, the Columbine with a Zipper fairing coasts away from the Trek with no fairing.

Picking the right tire size is a personal matter. Jim Merz, Specialized’s tire guru, weighs 190 pounds and rides narrow Turbo VRs. I asked him if he gets lots of flats. He answered, “I don’t get flats, I’m careful.”

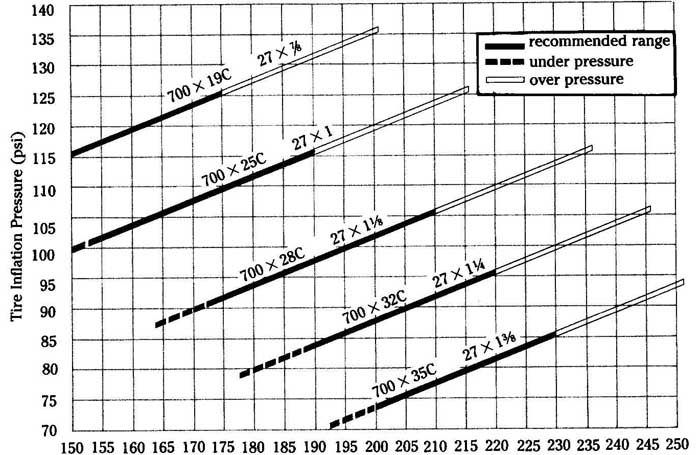

FIG. 4 is my effort to quantify rider and bicycle weight against inflation pressure and tire size. It’s my own idea. I couldn’t find anything like this in the manufacturers’ literature. It’s conservative, but take it as a starting point to pick your tire size and inflation pressure.

Weight

The total weight of the tire, tube, and rim is the most important weight on the bicycle. Most bicycle writers have written that they would rather pedal a Varsity with Paramount wheels than a Paramount with Varsity wheels. I’m not sure I agree, but it makes the point. The rotating weights on the outside of the wheel have the greatest influence on how a bicycle accelerates and how it feels.

The easiest way to reduce the weight of a tire is to reduce its size. A narrower tire takes less cord and rubber so it automatically weighs less.

A narrower tire has less air pressure force acting on the casing and the rim. The casing can be thinner and lighter and the tire can carry a higher pressure without blowing off the rim. The corollary is that a narrow tire must carry a higher pressure to support a given rider. On the surface, the obvious answer is to buy the lightest and narrowest tire that you can get away with. This is true as long as the light tire is comfortable and reliable. This gets right back to my first priority item: pick the right tire size.

For any given size, lighter tires cost more money. Thinner sidewalls, skinwall construction, finer cord thread, exotic Kevlar beads, and tight quality control all add to the cost. This is a classic “less is more” situation. The tire makers charge a legitimate premium for lighter tires.

Now comes the rub. Tire making isn’t a precise micrometer-controlled process. There’s a weight tolerance of about plus or minus 10 percent on production line tires. The manufacturer doesn’t list the heaviest tire in the batch or even the average one. Usually, he weighs a bunch of tires and advertises the weight of the lightest ones. Table 1 shows the advertised weight and the average weight of my two samples. Where you see a significant weight difference, it probably means that the tires that I weighed were different models from the tires that were weighed for the advertising.

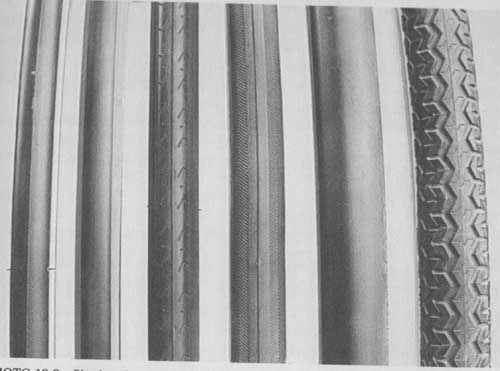

PHOTO 2 Six tire sizes (widths in parentheses): left to right, 700 X 19C

Specialized Turbo R (19mm), 700 X 23C CyclePro Linear F (20.5mm), 700 X 25C

CyclePro Discovery (23mm), 700 X 28C Specialized Touring II (24mm), 700 x

32C Avocet FasGrip Duro 20 (29.5mm), and 700 X 35C Michelin Hi-Lite Tour

(32mm).

There’s a sneakier approach to the weight game. You can label a tire as larger than it really is. That’s why I show the actual ISO-ETRTO section widths and the actual mounted widths in Table 1. Tires with the same section width are the same size.

__Feel__

Feel is often called “liveliness.” Either way, it’s what keeps the snake oil salesmen in business. Tubular tires feel great. You can hear them hiss over the road. Feel is an undefinable combination of many characteristics Some of these characteristics can be measured, including parameters like shock absorption, adhesion, and rolling resistance. Feel is also affected by inflation pressure, r sidewall flexibility, rubber compound, tread thickness, tread pattern (or the absence of tread), tire size, and type of rim.

FIG. 4 Tire size and inflation pressure in relation to weight of rider and

bicycle.

There are two kinds of adhesion: friction and mechanical linkage. The coefficient of friction measures how much force it takes to push a one-pound block of rubber along a given road surface. We old-school mechanical engineers were taught that it always took less than one pound, so the coefficient of friction was always less than one. The old textbooks had to be revised when drag racers began turning 200 mph in the quarter mile, which requires a coefficient of friction of more than one. That’s when we learned about mechanical linkage.

We now know that tires are literally geared to the texture of the road. Rubber compounds that provide good friction have poor mechanical linkage and the reverse. Both friction and mechanical linkage drop when you lubricate the surfaces with water. You can see the reason why the tire business attracts snake oil salesmen.

Cornering ability and adhesion are tied together. You can measure cornering ability by coasting around a constant radius corner faster and faster, which requires you to lean the bike farther and farther over. When the bike slides out, you measure the angle or the speed. Then you replace the tire (and probably the tire tester) with a different model and repeat the test. Fortunately, the cornering test can also be simulated in the laboratory on a very expensive testing machine. Unfortunately, the USA has 60,000 under-employed trial lawyers, so the test results are always confidential.

We know that overinflation causes bouncing instead of shock absorption on rough surfaces and this reduces adhesion and cornering ability. The most significant factor in adhesion is sidewall flexibility, which keeps the tire patch on the road. I don’t think I can properly predict adhesion from tire measurements so I don’t show a rating for it in Table 1.

__Rolling Resistance__

This can also be measured, either by coasting the bicycle down a slight ramp and measuring the speed or by measuring the deceleration of a loaded cart. Rolling resistance depends on rider weight, inflation pressure, road surface, and tire construction. When a tire rolls over a road, both the tire and the road deflect. When the tire and the road surfaces return to normal, not all of the energy that went into in the original deflection is recovered. The phenomenon is called “hysteresis.” The tire print left in a soft dirt path causes a major loss, which is why it’s so hard to pedal on soft roads. According to Frank Rowland Whitt and David Gordon Wilson in their book, Bicycling Science, the rolling resistance of the road surface can vary by a factor of five. In most cases however, the road hysteresis loss is minor.

The tire hysteresis loss is the significant part of the total rolling resistance. The more the tire flexes under load, the greater the rolling resistance. That’s why a high inflation pressure reduces rolling resistance on smooth roads. A steel wheel on a steel rail has minimum rolling resistance, but it rolls on an extremely smooth surface. On a rougher surface, a steel wheel not only gives an extremely uncomfortable ride, it also has a high rolling resistance. The pneumatic tire averages out the road bumps. When Doctor Dunlop invented the pneumatic tire a century ago, it was much more comfortable than the solid rubber tires previously used. On the rough roads of the period, pneumatic tires were also much easier to pedal.

Minimum-hysteresis bicycle tires with minimum rolling resistance should have thin, flexible sidewalls, a thin, flexible casing under the tread, a thin tread, and a thin tube. The rubber compound probably enters into the equation somewhere, but it’s not as important as the first four items. I measured the sidewall thickness, casing thickness, and tread thickness of the 50 pairs of tires. I used the measurements to calculate the rolling resistances shown in Table 1.

__Sidewall Thickness and Flexibility__

Sidewall thickness is very important and it’s also easy to measure. As part of my rough-and-ready tire quality evaluation, I measured the sidewall thickness at five points on each side. This thickness is shown in Table 1. Equating rolling resistance to sidewall thickness is undoubtedly an oversimplification, so I also asked the makers about sidewall construction.

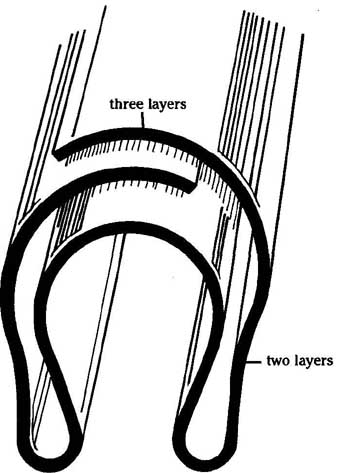

All of the tires except the Specialized Turbo VR and VS and the Michelin Hi Lites use the same construction. The casing consists of two plys of nylon cord in the sidewalls and three plys under the tread. The ply starts on the right side of the middle, goes around the left bead, back over the middle, around the right bead, and back over past the middle. (See FIG. 5.)

The Specialized Turbo VR and VS and Michelin’s Hi-Lite tires are special and they are described in the Specialized and Michelin sections at the end of this section. The sidewall construction of Michelin Hi-Lite tires is completely different from normal skinwall tires so Hi-Lite sidewall thickness isn’t comparable to the rest of the tires.

I also asked the makers what “denier” nylon cord they used. Denier Is similar to wire gauge. Larger numbers are smaller in diameter. Basically, the higher-quality tires use twice the number of cords in their plys, but the cords are only half as thick. The plys are coated with rubber and the excess rubber is squeezed out by rollers. More cord and less rubber provides a more flexible sidewall. This is the fundamental difference between gumwall tires, which have thick sidewalls with extra rubber on either side of the cord body, and skinwall tires, which have thin sidewalls with most of the rubber squeezed out. Of the two, gumwall tires are harder to pedal because there’s more rubber to deform. Still, according to Bicycling’s rolling resistance tests, the best of today’s high- pressure gumwalls don’t come off too badly, but you pay a significant weight penalty.

FIG. 5 Ordinary two-three ply tire casing construction.

__Casing Thickness under the Tread__

This is a continuation of the concept that flexible tires have lower rolling resistance. To differentiate between casing thickness and tread thickness, I started out by abrading the tread from brand-new tires so that I could measure what was casing and what was tread rubber. This was painful, even with free tires. After a while, I noticed that the casing under the tread on most of the tires was 1½ times as thick as the sidewall. This is logical because top-quality tires are made with two plys of cord in the sidewall and three plys of cord under the tread. After this brilliant discovery, I subtracted the calculated casing thickness from the total thickness. I still had to abrade the Kevlar-belted tires to find the thickness of the belt.

__ Tread Design __

There are four parts to the tread design equation: tread thickness, tread pattern, rubber compound, and rubber hardness. Tread thickness is the most important and it can be measured. The other three are important but they fall in the snake oil department. After listening to quite different stories from the experts at Avocet, CyclePro, Michelin, and Specialized, I have to say that they’re all honorable men, they all believe what they say, but they can’t all be right.

_____Tread Thickness _____

Tread thickness is very important to rolling resistance. Rubber has significant hysteresis loss; the more rubber, the higher the rolling resistance. It’s easy to measure tread thickness. I just measure the total thickness of the tire in the center and subtract the casing thickness. There’s usually a little ridge in the center where the mold closes, but the micrometer compresses it so that it doesn’t matter.

Tires with patterned treads are usually thicker than tires with smooth treads. There’s another side to this. You need a minimum amount of tread thickness to allow the tire to mechanically link to the road. Finally, tread thickness ties in with mileage and durability.

__ Tread Pattern __

Tread pattern is highly visible, but it’s probably less important than it looks. First off, some of the tread patterns are so thin that as soon as you’ve used the tire for a few hundred miles, you’re on smooth tread. Wet-weather adhesion is the crucial element. Avocet says that smooth treads grip best in the wet. Michelin and Specialized say something different. I don’t ride in the wet that much, and when I do, I don’t try to set any cornering speed records.

On my British Columbia loaded tour, we had 700 X 32C Avocet FasGrips on one bike and 700 x 35C Michelin Hi-Lites on the other. I pedaled both bikes on the day it rained. The main difference was the extra 10 psi in the Avocet tires. I’m willing to believe Michelin’s ads that wet-weather adhesion is improved by sipes or radial grooves to squeeze out the water, but I suspect that it’s more important in automobile tires. I’ve got 700 X 28C Avocet tires on my sport touring bike. They corner very decently, although I haven’t approached the lean angle shown in the Avocet ads.

___ Rubber Compound and Rubber Hardness ___

I’m sure that there are significant differences between the rubber com pounds used in the different tires. I haven’t seen any measurements that indicate that one rubber compound is better than another or that hard rubber is better than soft rubber, but it seems logical that hard rubber should wear better and that soft rubber should adhere better. I suspect that hysteresis has more to do with both wear and adhesion. For the mileage, durability, and rolling resistance ratings in Table 1, I assumed that all the rubber was the same.

PHOTO 3 Tire treads: top to bottom, smooth tread on Avocet FasGrip, minimum

tread on Specialized Turbo VS, siped tread on CyclePro Discovery, and deep

tread on Michelin Hi-Lite Tour.

__Durability and Mileage__

Almost all of the tire features that make for good feel and low rolling resistance also make for poor durability and low mileage. I define durability as resistance to punctures and other failures. Mileage is the number of miles before the tread wears through. I throw away far more tires with durability failures (sidewall and tread cuts or ozone cracks) than I do with worn out treads. My son, the racer, trains on light clinchers and he has the opposite experience.

It’s a classic compromise situation. You have to decide what’s more important to you, lively feel or minimum care. It’s nice when you have two (or more) bicycles. Then you can pick the bicycle with the tires that suit your mood for each ride. You can get much of the benefit with two sets of wheels, but it takes a bit of time to switch.

__Durability__

There are two kinds of durability: puncture resistance and casing integrity. They’re both covered in the durability column in Table 1. 1 arrived at the durability rating by adding the thickness of the tread, the thickness of the casing, the thickness of the sidewalls, and my own personal riding experience. For greater durability, you can either use wider tires with thicker treads or you can use special puncture-resistant belted tires.

Puncture Resistance You avoid punctures by using a tire that’s wide enough. On the surface, it would appear that a wide tire sweeps a wider stripe of road, therefore it rolls over more glass and gets more flats. Not so! A skinny, high-pressure tire presses much harder on the road and it has a much thinner tread. A fat tire shrugs off tiny pieces of glass that puncture a skinny tire. The fat tire also avoids snakebite flats because there is more air volume to absorb bumps and potholes before the rim bottoms through.

Some riders are much more observant than others. I notice that when I draft my son, he always points out the glass on the road. When I lead, I just roll right through it, which makes him indignant, especially when he’s riding tubulars.

Broken glass also affects how far you keep to the right, If you stay out to the left, you’ll be on the part of the road that’s swept by the cars. You’ll also have more cars waxing your left pant leg as they pass too close. The throw-away glass bottle and the throw-away mentality is the bicycle tire’s worst enemy. States with bottle bills are more pleasant for bicyclists. (The lobbying organization for the throw-away bottle makers calls itself “Keep America Beautiful.”

How’s that for chutzpah?) So, match your tire selection to your riding style and your road surfaces.

Casing Integrity The sidewalls on the top-quality skinwall tires are so thin that they’re translucent. Light passes through them and so does glass. Because the sidewall is so highly stressed, even a tiny cut destroys the tire. You can patch it with a piece of duct tape and pedal home but you’ll never be able to hammer it up to maximum pressure.

There are lots of other failure modes. Hooked-edge rims cause the tire to bend around a sharp radius corner. The tire has a special strip of tape to prevent cord chafing at this point, but I’ve had flexure failures at the base of the sidewall. Then there’s ozone and aging cracks. The classic test for ozone is to bend a section of natural rubber, expose it to the smoggy atmosphere, and wait for the cracks to appear. The tire makers use additives to increase ozone resistance. One saving grace is that top-quality tires have very thin treads, so they usually wear out before they smog out. However, when you have lots of bikes or lots of wheels, it takes longer to pile on the mileage.

If you ride on poor roads or you don’t consciously avoid glass, you have another option: belted tires. The casing construction of Michelin’s Hi-Lite tires is inherently puncture resistant. The Avocet FasGrip K20, CyclePro belted Discovery, and Specialized Touring II-K4 are puncture-resistant tires with a Kevlar belt under the tread. You pay a feel and rolling resistance penalty because the Kevlar armor belt isn’t as compliant as the nylon plys, so there’s more hysteresis loss. Avocet claims that their Kevlar belt is specially designed to reduce this penalty. Thorn-proof tubes and belts that you install between the tire and the tube are much worse. They make your tires feel as though they’re inflated with sand.

__Mileage__

Tire mileage depends on rider weight, inflation pressure, road surface, and slippage. Front tires typically last three times as long as rear tires because all of your power goes through the more heavily loaded rear tire. Braking also wears away the rubber. If your rim has a wide spot, it will cause the brakes to lock at that point and wear out a spot on the tire tread. If you use smooth tires, don’t plan to ride them until the cord shows through. You lose adhesion when the tread gets too thin and you’ll get more flats in the last quarter of a tire’s mileage. I usually throw my wide touring tires away while they’ve still got tread, because of the aging cracks or because I’m tired of looking at them.

The mileage rating in Table 1 is based on tread thickness, tire size, and the ratio of rubber to voids in the tread pattern. For a given tread thickness, a smooth tread will wear longer because there’s more rubber and less air. An excellent-mileage tire should last at least 4,000 miles on a back wheel. A poor- mileage tire should last about 1,000 miles.

_____ Tire-Rim Compatibility _____

I’ve already talked about the two rim and tire diameters, 27-inch and 700C. They have to match or you won’t be able to mount the tire. There are two other factors involved in tire-rim compatibility. The rim has to be the right width for the tire and it has to have the right kind of edge construction.

____ Rim Width ____

The only rim dimension that matters is the inside width. There are three inside widths: narrow (13mm to 14mm), medium (15mm to 16mm), and wide (16.5mm to 20mm). (Rim inside widths are listed in Table 3 in section 11.)

Narrow rims are for narrow tires and wide rims are for wide tires. Tire size 27 X 1 1/8 or 700 X 28C is the transition. It’s about the widest tire that you can use with a narrow rim and the narrowest tire that you can use with a medium rim.

Fitting a wide tire on a narrow rim doesn’t properly support the beads. The tire may blow off and it will certainly ride in a squirmy fashion. A narrow tire on a wide rim can’t take the proper round shape and it will be very prone to snakebite punctures.

The 18mm- to 20mm-wide rim is ideal for 27 X 1% or 700 X 35C loaded touring tires. Unfortunately, wide rims that come with hooked edges are hard to find. You’re much better off with a medium-width, hooked-edge rim than you are with a wide, straight-side rim. Table 1 shows the minimum and maximum rim inside widths suitable for each tire model. They are based on the ISO ETRTO recommendations. According to my “bible,” Sutherland’s Handbook for Bicycle Mechanics (4th ed.), tires with section widths between 1.4 and 2.0 times the rim inside width should fit well. If you’re trying to find tires to fit uncommon rims, Sutherland’s Handbook is an indispensable guide.

__Bead Material and Rim Edge Type__

The main reason to use a Kevlar bead is to save 50 or 60 grams per tire compared to the same tire with a steel bead. The second advantage is that you can fold a Kevlar-beaded tire since the bead is flexible. The Japanese Kevlar beaded tires are a bit prone to stretching. They are made on the small side, which makes them harder to mount. Michelin’s Hi-Lite tires have a different kind of Kevlar bead, which stretches less. They’re made slightly larger so they mount easier and Michelin allows use of some sizes of tires on rims that don’t we a prominent hooked edge.

If you use foldable tires with Kevlar beads, you must use hooked-edge rims. , if the bead stretches a bit, the tire will blow off. If you plan to use high-performance skinwall tires with steel beads at full inflation pressure, you should also use hooked-edge rims. They provide more security against blow off. When you see a tire with a reinforcing tape over the bead, you know the maker was thinking about hooked-edge rims. If the tire doesn’t have the reinforcing tape, it may chafe through where it bends around the sharp-radius hooked edge; this probably won’t happen for a few thousand miles.

If your present rims have straight sides or just a vestigial hook, use tires with steel beads and keep your inflation pressure down a bit. Tires can’t be made with zero tolerances. A maximum size tire at maximum inflation pressure will probably blow off a straight-side rim.

__Road Test Results__

When I had completed the first draft of this section, I gave it to five different experts for their review and comment. I was particularly interested in their input on FIG. 4 where I make recommendations on tire size and inflation pressure in relation to rider weight. The response was unanimous. All five were successfully using narrower tires than I recommended. I had a shop full of tires and I had to mount them on rims to measure the mounted width. So, for a three-month period, I rode a different set of tires on every ride. With careful mounting and careful riding I was able to test ride the 700 X 19C, 20C, and 23C tires.

I’d like to tell you that I have a vernier caliper on my backside and the results of the road test confirmed my calculated tire ratings, but that would be a lie. I can readily tell the difference between a tire with an “excellent” rolling resistance and one with a “good” rolling resistance. But, I wouldn’t want to wager that I could tell a “good” tire from a “very good” tire in a blind test.

Here’s what I learned in the process of riding 50 different tires:

• Good-feeling tires hiss as they roll but a head wind or a tail wind masks a lot of rolling resistance.

• Polyurethane tubes are a significant improvement. They’ll raise any tire one rating.

• When you overinflate wide tires, they feel like you’re riding on the rims. A 700 X 20C tire at 125 psi is much more pleasant to pedal than a 700 X 28C tire at 125 psi.

• You should use a good rim tape (Velox) and mount and inflate narrow, high-pressure tires very carefully. I always dusted the tube with talcum powder. I was able to mount most of the tires without using tire irons.

I experienced six flats in the three months (and 1,200 miles) of tire testing. Two were punctures. One was a snakebite and three were just strange pinholes that appeared in the tube on the rim side. Most of my previous flats with narrow tires were caused by poor mounting rather than punctures.

___ Tire Makers and Distributors ___

Just four companies make top-quality bicycle tires: Inoue Rubber Company (IRC), Michelin Tire Corporation, Mitsuboshi Belting Limited, and National Tire Company. In the USA, the three Japanese companies sell most of their tires under different names. Inoue makes tires for Avocet and West Coast Cycle. Mitsuboshi makes tires for Specialized. National makes tires for West Coast Cycle, Western States Imports, Schwinn, and others. West Coast Cycle calls their tires CyclePro. Western States Imports calls their tires Panaracer.

Avocet and Specialized have done considerable research and development work with their Japanese suppliers so that their tires are unique. Still, most Japanese tires are quite similar. Michelin Hi-Lite tires are quite different. Most bicycle stores contract with one of the major distributors for their complete tire requirements to get the best possible volume price. Michelin distributes their bicycle tires themselves.

I picked the four largest distributors and I’ve listed all of their top-quality tires in Table 1. 1 also show their best-selling economy skinwall or top-quality gumwall for the bargain hunters.

Avocet

Avocet got into tires in 1985. They’re convinced that smooth treads are the proper approach for both wet and dry conditions. FasGrip tires use a special rubber compound for smooth tread service. Avocet showed me the results of their rolling resistance and adhesion tests. Some of the tests involved the kind of brute force and awkwardness that appeals to me. They paved several sheets of plywood and arranged them so that they could be tilted at an angle. Then they rode bicycles across them and increased the angle until the tires lost traction. They played the same game with water running down the paving. In 1987, Avocet introduced the FasGrip K20, a Kevlar-belted tire with the belt woven from a special Kevlar mixture to minimize energy loss. Avocet claims that the rolling resistance of their belted tire is only 4 percent higher than the non-belted model. The usual penalty is about 30 percent.

Avocet calls their steel-beaded tires FasGrip 20. The Kevlar-beaded tire Is called FasGrip 30. The Kevlar-belted model with steel beads is called FasGrlp K20. Avocet’s width and model designation is logical. Each size has a different name. The 700 x 20C Time Trial tires have a very thin tread and they’re designed for light riders on smooth roads. The 700 X 25C Criterium has a one- third thicker tread than the Time Trial. I’ve used them successfully and they’re very lively. The 700 x 28C Road has a one-third thicker tread than the Criterium and the 700 X 32C Duro has a one-third thicker tread than the Road.

I fitted Duros on one bike and Michelin Hi-Lite Tours on the other for my 1986 British Columbia trip. I hoped to be able to give you all kinds of insightful advice, but you don’t get a whole lot of liveliness feedback from a loaded touring bike. Both tires felt almost exactly the same. The Duro was a bit firmer riding, but it was narrower and carried ten more psi.

CyclePro

West Coast Cycle distributes CyclePro tires and accessories and Nishiki bicycles nationwide. CyclePro Discovery tires are made by IRC and CyclePro Linear tires are made by National. The Discovery has IRC’s unique oval shape. They accomplish this by making the tread about 50 percent thicker and about half as wide as a typical skinwall tire. It’s almost like a wide, raised-center tread. CyclePro says that all of the Discovery tires have been tested to wear 3,000 plus miles. The Discovery is available in four models, with or without Kevlar beads and with or without a Kevlar belt. The Linear is the smooth tread model that features National’s dual hardness concept, harder rubber in the center of the tread for long wear and softer rubber on the edges for better cornering.

Michelin

Michelin’s Hi-Lite bicycle tires are different. Vive Ia difference. Michelin has always been innovative. Fifteen years ago, their Chevron 50 was the first high- performance bicycle tire. The Elan was the first narrow tire and the Elan RS was the first Kevlar-beaded tire. The Elans weren’t very nice narrow tires, but they proved the concept of narrow, high-performance clinchers. I get the idea that the Japanese tire engineers look over each other’s shoulders. Michelin doesn’t look over anyone’s shoulder.

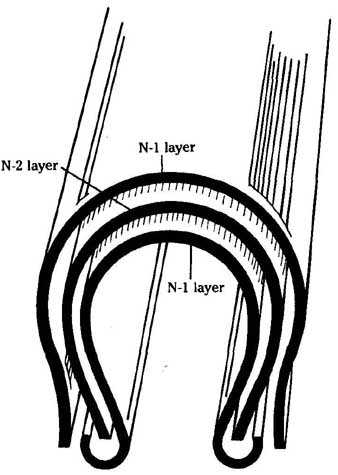

The Hi-Lite series of tire is a real breakthrough. Michelin wanted a very flexible carcass but they didn’t want to pay the durability penalty involved in thin sidewalls. Hi-Lite tires don’t fit into the two-three ply pattern. Their unique three-ply carcass construction uses a two-way mesh instead of parallel cords. A fine-mesh, pressure-containing ply, which Michelin calls N-2, is sandwiched between two coarse-mesh plies, which Michelin labels N-i (see FIG. 6).

Based on my experience, 1 think that the Hi-Lite package offers the best combination of durability and performance. The 700 X 19C Hi-Lite Pro is the lightest model. In the course of riding it about 300 miles, I only had one puncture and one snakebite flat. The Hi-Lite Pro includes a wedge of rubber to fair the tire to the rim for minimum wind resistance. Hi-Lite Comps come in two sizes, 700 X 20C and 700 X 23C. These have an extra belt of nylon under the tread for better puncture resistance. I’ve used the 23C for more than 1,000 miles. Both the Pro and the Comp are sweet-handling tires. Hi-Lite Roads have a fine tread, no extra belt of nylon and a thicker tread for longer wear. The 700 X 35C or 27 X 1% Hi-Lite Tour is Michelin’s super tire for tandems and loaded tourists. It’s my favorite loaded touring tire.

Michelin’s Select tires are conventional skinwalls, designed and priced to meet the Japanese competition. They also have “approximate” size designations to match the competition.

I feel that Michelin tires are more subject to ozone cracking than other top- quality brands. But, it may just be that the treads wear for so long that the sidewalls show the ozone cracks. The only other negative feature I see in the Hi Lite tires is that they look different. I think they’re ugly.

Specialized

Specialized got into bicycle tires in 1976. They hit on the idea that buyers would pay a premium for a better-quality, better-performing tire. They picked up the narrow, high-performance clincher idea and ran with it. The Specialized Turbo was their breakthrough tire and I just happened to write a comprehensive article on tires when it was introduced. My tire testers loved it. So did the buyers, and the dealers couldn’t keep them in stock for six months. I was very enthusiastic about the raised center ridges of the old Specialized Turbos, though there’s now pretty general agreement that a raised center ridge adds more to rolling resistance than it subtracts. The key point was that the Turbo was the first widely available, high-performance clincher tire with a thin, flexible sidewall. I credited the center ridge instead of the tire construction. Today, Specialized sells more tires than anyone and their lineup is the most complete.

The top-of-the-line Specialized tire is the Turbo VS and VR. (“S” means rough tread and “R” means smooth tread for some inexplicable reason.) These tires grew out of a program to develop a breakthrough mass production tubular tire. Specialized abandoned the tubular program because the market was too small. However, the research results indicated that a very high performance clincher could be made at a high price. The VR and VS are the most expensive clincher tires made. They use a proprietary cotton-Kevlar casing and they’re two-ply rather than two-three-ply. There’s almost no rubber in the sidewalls.

The labeling on these tires is odd. They have a 20.5mm mounted width and a 23.5mm actual section width. The tire label says 700 X 25C and the ISO ETRTO label on the sidewall says 622 X 20. Take your choice.

The skinniest Specialized tire is the 700 X 20C Turbo R. Specialized also makes the steel-beaded Turbo LR and LS series at a lower price. The Touring II series for general sport touring is their best-selling skinwall clincher. The Touring II-K4 has a Kevlar belt. The Touring X is a lower-priced, heavy-duty skinwall. The market for extra-wide loaded touring tires was so small that Specialized stopped importing my favorite 700 X 35C Expedition tire. I show it in Table 1 because it’s still available. I’ve now switched over to the Michelin Hi-Lite Tour.

Everybody Else

Everybody else consists of the other people who import IRC and National tires and sell them under different names. National Tire and Panasonic Bicycle Company are both divisions of Matsushita Electric. Western States Imports is the U.S. importer and distributor for Panasonic bikes and National’s Panaracer tires. Schwinn’s top-quality tires are also made by National. IRC has it’s own distributors, and tires labeled IRC are widely sold.

FIG. 6 Michelin Hi-Lite tire casing construction.

__ Tube Selection __

It’s funny, the same person who will endure all sorts of pain and suffering to save 50 grams of tire weight will waste most of the saving by using heavy tubes. Find a tube that matches your tire selection and it will make a surprising difference. The new polyurethane tubes are a real breakthrough. They make any tire feel like it’s one size lighter. All tubes of the same type are about the same so I haven’t picked a favorite. I’ll cover the important tube features in order of their importance (these features are all shown in Table 3).

_ Size and Weight_

The same tubes are used for both 27-inch and 700C tires. Tubes come in three or four different sizes (widths). Tubes stretch so that you can stuff a fat tube into a skinny tire but it will really degrade the performance. You can also put a skinny tube into a fat tire, but you’ll get a few more punctures and snakebite flats. As a general rule, use the same size tube as the tire.

Cheap tubes are heavy. Light tubes cost more money because it takes better quality control. It’s less expensive to save weight with tubes than with tires.

____Material ____

The basic choices for tube material used to be butyl and latex: Butyl rubber is a much more forgiving tube material, although it absorbs more energy than latex. The important thing is to buy the right size. Latex tubes are lighter and they have a better road feel. However, latex tubes are fragile. Sometimes they go flat all by themselves. (My bad vibes on latex tubes may be because I used to use them on my ultra-skinny tire tests.) Sometimes when a latex tube gets punctured, it self-destructs with a big long rip. This can be distressing since they cost ten bucks or so. Finally, latex tubes don’t do a very good job of holding air, so you have to pump them up before every ride.

Many people think that since latex tubes work well in tubulars, they’ll be fine for clinchers. The tubular tube, safely sewn inside it’s sleeping bag leads a much easier life than a clincher tube. The clincher has to adapt to the transition from tire to bead seat to rim tape, and the tube moves around as the tire deflects.

Polyurethane is the hot new tube material. It has even more liveliness than latex. Polyurethane tubes also resist punctures. Still, they have their disadvantages. They don’t like to stretch at all, so you have to buy the exact size (both diameter and width) to match your tire. If you do get a puncture, you have to use a special patch repair kit and the patch has to cure for 20 minutes before you can use the tube. As I write this, polyurethane tubes are just coming into general use and their problems are being defined.

__ Valve Type ____

There’s no contest in the valve department. Use Presta valves, not Schrader valves. The Presta valve is faster to inflate because it doesn’t have a spring and it loses less air when you pull off the chuck, It’s the only valve you can use with very narrow rims. The smaller hole weakens the rim less, it seals tighter, and it’s even five grams or so lighter. Use Presta valve tubes even if your rims have big Schrader valve holes. You can put a washer of rubber around the valve stem or not. (Tourists sometimes order Schrader holes in their rims even though they plan to use Presta tubes, so that in a pinch, they can use a Schrader tube.) Some cheap tubes have bolted rather than vulcanized valves. Don’t use these in narrow rims. There isn’t room for the valve and the tire beads.

_____ Rim Tape_____

When you use lightweight tubes, narrow clincher tires, hooked-edge rims, and very high inflation pressures, you get flats for all kinds of interesting reasons. To prevent the spokes or the rim from puncturing the tube, you need a good rim tape. There are four kinds: rubber bands, reinforced plastic bands, strapping tape, and Velox tape. Rubber bands are only suitable for inexpensive single-wall rims. Double-wall (box-section) rims have big spoke recesses in the inner wall. They need a stronger rim tape, especially at high inflation pressures. You want a tape that’s wide enough to cover the holes, but not so wide that it covers the bead seat.

CyclePro, Michelin, and Specialized make bands of reinforced plastic. These work well if they’re exactly the right width for the bed of the rim. Otherwise, they move around and uncover the spoke holes. CyclePro makes two widths and the narrow width is just right for dropped-center rims.

Fiberglass-backed strapping tape is used to seal cardboard boxes. It’s available in 3/ and ½-inch widths. I had good luck with it until my first trials with 700 x 19C tires and 130 psi pressures. I found that if I used two overlapping layers of tape, it was too thick and it was hard to mount the tires, and one layer wouldn’t always keep the tube out of trouble.

Velox rim tape is made in two widths, #56 for rims with a narrow dropped center section and #51 for the double-wall rims without a dropped center section. Velox tape is fussy to use, but it’s worked well for me.

Favorite Tires and Tubes

In most of the other sections, I tell you exactly what I like and why. Tires aren’t so cut and dried. Many of the Japanese tires are similar. For a given size and inflation pressure, it’s difficult to feel the difference on the road, especially when you get away from the exotic ultra-light models. I believe in smooth treads. After I completed my tire-a-day tests, I picked five different tires for my five bikes. (Next year, I’ll probably be using something different.)

Working our way from the lightest to the most rugged, the Trek has 700 X 23C Michelin Hi-Lite Comps. If I use any other tire that small for the long pull, I get too many punctures. The Schwinn Paramount has 27 X 1 Avocet Criterium 30s. The Redcay has 27 X 1 1/8" Specialized Turbo Rs. The Windsor commute bike has 27 x 1 1/4 Specialized Touring lI-K4s and the Columbine has 700 X 35C Michelin Hi-Lite Tours. I used polyurethane tubes in the lightweight tires.