Tools needed for most repair/maintenance work on pedal axles:

The axle of a pedal is usually made from steel and the crankarms from aluminum alloy. This creates an interface where a chemical reaction can take place between the two metals, so it is important that you coat the threads with grease before you put pedals on your bike. The tools for removing the axles are specific to the brand and model of the pedals, and are either supplied with the pedals or available at a good bike shop.

Most pedals contain two bearings on which the pedal body revolves around its axle. These sometimes need replacing; in the case of ball bearings, they need regular cleaning, checking, and greasing.

Pedal axles can be damaged by an impact or during a fall, and a bent axle can cause riding discomfort or even injury. After removing the pedals, rotate their axles by hand, feeling for the tight spots that are evidence of a bent axle.

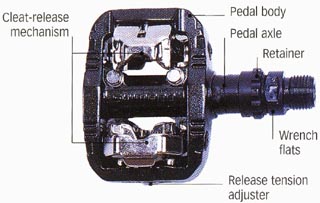

Below: Parts of a pedal: axle, cleat-release mechanism, pedal body, release tension adjuster, wrench flats, retainer.

CLICK HERE to shop for pedal products

Read our article on How to Pedal on a Bicycle

Removing and lubricating a pedal axle

1. Turn the wrench counterclockwise for the right pedal, which has a right-hand thread, and clockwise for the left pedal, which has a left-hand thread.

- Place a wrench on the flats of the axle to remove a pedal.

- Steady the opposite crankarm with your hand to give you something to push against.

2. Hold the removed pedal, with the axle upward, in a vise.

- Remove the axle by using a remover tool that fits over the knurled retainer connecting the axle to the pedal.

3. Ensure that the remover tool fits snugly onto the retainer. The retainer may be damaged if you do not.

- Place a wrench on the flats of the remover tool in place and turn it to remove the retainer.

- Turn the wrench clockwise for the right axle retainer, which has a left-hand thread, and counterclockwise for the left axle retainer, which has a right-hand thread.

4. Lift the axle from the pedal once you have fully unscrewed the retainer nut.

- Clean the axle with degreaser and inspect it. If the axle is bent, it will need to he replaced.

- Replace the hearings on the end of the axle if they are worn.

5. Hold the cone with one wrench and remove

the locknut with another. The cone and

locknut hold the hearings on the end of the axle.

5. Hold the cone with one wrench and remove

the locknut with another. The cone and

locknut hold the hearings on the end of the axle.

- Remove the cone, then the old bearings. Clean the end of the axle.

- Set the new bearings in grease and screw the cone back on top of them. Then lock the cone with the locknut.

6. Grease the inner bearing to prolong its life. If it is worn, the whole axle assembly must be replaced.

- Push some grease down into the bearing after cleaning the axle. To reassemble the pedal, carry out Steps 1-4 in reverse order.