PART IV

Italian Frame Builders

Italy has become known as the home of cycling, a place where you can buy everything you'll ever need for riding.

Everything from spoke nipples to the machinery used to manufacture them can be found in Italy. The Italian frame builder has become an innovator and leader in frame design since he works closely with the component manufacturers in designing prototypes. When a component manufacturer, such as Campagnolo, releases a new product, you can be sure the Italian frame builders have been using it for months.

The Italian frame builder is unique in the world because of his close association with the riders and coaches. They work collectively to optimize cycling efficiency. Frequently, the builder has had personal racing experience, but, unlike his British counter part who was a time trialist, the Italian builder met with success in international mass-start races. Consequently, he is able to understand the needs of bicycle racers.

On the other hand, the Italian builder does not recognize the need for lightweight touring frames. In fact, we were unable to find any custom Italian touring bicycles. Although Italian frames may be used for touring, their builders are generally too involved in racing to devote any time to the design requirements of the tourist.

Italy has a disproportionately high share of the world's master builders. Some of the most revered builders (Cinelli, De Rosa, Pogliaghi, Colnago, and Masi) are Italian. Almost every little hamlet in Italy has its own frame builder.

The Italian builders are the most style conscious of all builders. They are interested in producing a frame that is aesthetically pleasing as well as functional. Their frames incorporate the latest examples of design theory. Like the famous Italian sports cars, the bicycle frames are built to look as fast as they perform.

The high-quality Italian frames are usually built with Colum bus tubing because of the proximity to the Columbus factory and, in part, because of their strong sense of patriotism. All frames are built to accept Campagnolo components.

Cinelli Cino & C.

Via Egidio Folli 45 Milano 20134, Italia

Cino Cinelli is 61 years old and his interest in bicycles has spanned almost half a century.

Cino was born in 1916 in a small farmhouse just outside Florence in the province of Tuscany. He was the seventh of 10 children raised by Enrico Cinelli and his wife Marianna Banolli. Cino spent his early childhood on his parent's farm which included 36 square quadrameters of land devoted to growing grapes for chianti and olives for oil.

For the average Italian in the late 1920s, there were only three means of transportation from the countryside to the city: by foot, horse, or bicycle. Traveling by foot was too slow, and owning a horse was too expensive for the everyday farmer. Naturally, the bicycle became the most popular means of transportation. Cino got his first bicycle in 1929 when he was 13 years old. In those early days, Cino would ride to school in Florence with his brothers and sisters. Unfortunately, this was a difficult economic time for both Italy and the Cinelli family. Their modest farm could not support the large family and the older children had to quit school and go to work.

Arrigo and Giotto got jobs working in a bicycle store. Although it was a small store, the owner was an artisan who specialized in building racing frames. Arrigo's enthusiasm for his job spread throughout the family. Frequently, Cino would accompany his brother to work just to be able to look at the bicycle equipment.

In spite of the scarcity of jobs, Cino was lucky and got a position with a publishing firm in Florence, near the store where Arrigo worked. Once again Cino was able to ride with his two brothers Arrigo and Giotto, just like they had done while going to school. Their natural competitive spirit changed their commuting miles into three-man races held every day to, and from, work. This was the beginning of a career that would take Cino from commuter to professional bike rider, from unknown frame builder to manufacturer of some of the most respected bicycles and bicycle components in the world.

As the oldest of the Cinelli brothers, Arrigo started racing first. Giotto, and then Cino, soon followed. The Cinelli brothers did not have an easy time of it since their father vehemently disapproved of their bicycling activities. He thought that his sons would be better off spending their time in other more accepted, as well as more profitable, sports like horseback riding or target shooting. Although the brothers respected and feared their father, they were determined to become champion bicycle riders.

Background

Their refusal to accept their father's advice demonstrated their strong will and determination. Although their father was a fair and honest man, the people throughout Tuscany feared him because of his great strength. This fear stemmed from Enrico Cinelli's almost miraculous transformation from a frail child to a strong adult. Cino's respect for his father was obvious as he related this story, which was interrupted by fits of laughter.

When Enrico was a young child, his mother became so concerned over his poor health that she consulted a doctor for help. The doctor's advice was unorthodox, but she blindly ad ministered the prescribed "cure." The doctor had advised her to feed Enrico a bowl of soup "fortified" with iron shavings! Enrico ate this soup every day for three years and became one of the strongest men in Tuscany. His daily consumption of iron filings became legend and he became known as the "iron man." Arrigo raced for two years in the amateur class and discovered that he wasn't as good as he thought. He had visions of winning the Giro di Lombardia, but had difficulty winning local races.

Unlike Arrigo, Giotto began winning many of the races he entered. As Giotto started winning races and became a local hero, it was difficult for Enrico Cinelli to forbid his sons to race.

Although Enrico never fully sanctioned his sons' racing, he became proud of their achievements.

Cino started racing in the junior category at the age of 15. Like Giotto, he won many of the races he entered. Cino was not a very muscular youngster and many people believed that he would never be a top-caliber rider. Some thought that his physique would limit him to becoming a gregario (a rider who is not paid to win but instead is paid to support a selected member of a team).

Gino's determination and training paid off because each year he became stronger, more confident, and won more important victories.

In 1935, when Cino was 21 years old, he entered the senior amateur category. At this time he was still working in the publishing business. Fortunately, his employer was good to Cino, allowing him to work only half days so that the remainder of his time could be devoted to training. A major change in Cino's life occurred when his boss was replaced. His new manager gave Cino an ultimatum: work or train. Since his winnings had been providing enough money to live on, Cino chose to make his livelihood from his greatest love: cycling.

Cino became the hope of Tuscany with Giotto's retirement.

Cino won so many races as an independente that he was practically forced into becoming a professional. Lucrative professional offers came quickly. Cino rode for Frejus in 1938 and 1939; and for Bianchi from 1940 to 1943. Cino won many of the great Italian classic road races: the Girodi Lombardia, the Giro di Piedmont, the Giro di Campania, and the Milan-San Remo. These victories were major accomplishments since Cino was riding with some of the greatest racers of all time-Gino Bartali and Fausto Coppi, to name only two.

When World War II broke out, Cino was required to join the army. Mussolini shared his country's love of cycling and the bike racers were not sent to the war front. Instead, they remained in Italy and continued racing. Although the war reduced the number of races, they were no less competitive. Once Mussolini's Fascist government was overturned, bike racing activities came to an end until after the war. Cino officially retired from racing in 1944, on the day he won the Milano-Varese stage race. His decision to retire had been partially affected by the damage the war had inflicted on his country. The track in Milan had been bombed to ruins and all road racing activity had virtually ceased with the invasion of the Allied forces. Although some local races were still held, all of the major races were canceled because of the increased war activity.

Building Philosophy

During his racing career he had become increasingly aware of the inadequacies of his racing bicycle. Cino did not resume his racing activity after the war like Bartali and Coppi; he had other plans. He became more contemplative than competitive. World War II created just the interruption needed to direct Cino's time and energy to activities other than training and racing.

During Cino's racing career he developed amiable relations with many people in the bicycle industry. He became acquainted with factory representatives as well as owners of bicycle factories, including Benotto.

During his employment with Benotto, Cino devoted his spare time to design improvements of bicycle frames and parts while his...

Figure 14-1: The Cinelli workshop.

...wife, Hedi provided administrative assistance. Unlike Cino, she was neat and efficient, and made sure that everything went like clockwork. They were a very complementary team. He provided the ideas spawned by his cycling passion and she assembled a business structure that brought his ideas to fruition. Their only child, Andrea, was born during this very busy time in their lives.

The first two years of the Cinelli business were not devoted to frame building or to the manufacturing of parts. Typical of Cinelli's usual thoroughness, two long years were devoted to the design of products that would be superior to anything currently available. If not, they would never bear the Cinelli name.

The first problem Cino set out to tackle was the lack of stiffness he had experienced in the bicycle equipment he used while racing professionally. Cino had developed into a powerful sprinter and was not satisfied with the products available at the time. They were not rigid enough. His concurrent goals were improved aerodynamics and reduced weight without decreased strength.

Although Cino was neither a mechanical nor a design engineer by trade, he had an innate talent that is hard to duplicate.

He constantly discussed problems involving strength and aerodynamics with the experts of his time. Because of his enthusiasm and innovative ideas, they assisted him with the structural testing and the benefits of their formal education. Cino synthesized his racing experience with their technical opinions, and manufacturing began in 1947. Although he began producing custom frames at this time, his first real product was a set of lightweight-alloy handlebars that were almost as strong as the steel counterparts.

His handlebars became the standard of the industry, and even today they are the first choice of virtually every bicycle builder.

Today, Cinelli Cino & C. occupies a group of small buildings at Via Egidio in an industrial section of Milan. Cino is still very fit and rides about 200 to 300 kilometers (120 to 180 miles) per week.

Currently, Cino is riding his new prototype bicycle which will be covered in more detail later.

Cino Cinelli has not personally built bicycle frames since the early 1960s but he still supervises every single operation that is done by the two frame builders he employs. All the Cinelli frames are hand-built on the premises using acetylene and oxygen-fed hand torches. The demand for Cinelli bicycles is so great and their production capability is so small, that during an Olympic year, production only meets the demand of Olympic teams. Everyone else has to wait until the following year to put in their order. As a result of Cinelli's ability to understand the rider's needs, he had a virtual monopoly on track frames used from 1960 through 1970.

The Cinelli philosophy is to keep frame production at a level that will allow perfect quality control. In spite of the fact that Cinelli's are more expensive than even the most popular custom frames, Cino claims that his attention to detail results in every frame being sold at a loss! The majority of sales revenue comes from the sale of Cinelli lugs, fork crowns, bottom brackets, seats, handlebars, and stems. Cinelli Cino & C. would rather market their component parts because of the decreasing number of skilled workmen "willing" to build frames. Willing to Cino means more than just having the desire; the builder must work as if his name appeared on frame and not be working for the salary alone.

Consequently, yearly production rarely exceeds 350 frames.

Many Cinelli innovations have become standards that are accepted by the bicycle industry. For instance, one of the first design changes Cino made on his bicycle was the fork crown. The Cinelli fully sloping crown was a revolutionary design in the 1940s since all the fork crowns in those days were flat. There are two advantages with the Cinelli fully sloping fork crown- superior aerodynamics and increased strength.

The reduced frontal area of the fully sloping fork crown results in less wind resistance-a factor that geometrically in creases as speed increases. Moreover, the overall fork as a unit is more rigid with the fully sloping crown because the length of the fork blade is reduced. The solid cast crown is unexcelled for integral strength and when combined with the shorter fork blades, the combination is unsurpassed in rigidity, Cino's prime concern.

Frame Selection Cinelli-style forks are usually preferred on frames where rigidity is more important than comfort. Cinelli further justifies the use of the crown by its relation to the frame. When building a fork for stiffness, he believes it must be in harmony with the rest of the frame. The forks must be as stiff as the main and rear triangles. No more, no less. There is little value in building a fork that is more rigid than the main triangle or rear-stays since they will work at "cross purposes."

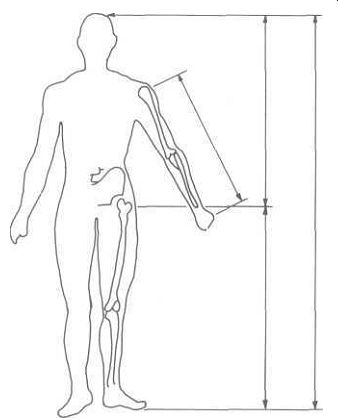

Figure 14-2: This is a copy of a card used by Cinelli to determine the

measurements necessary to build a custom frame. Cino Cinelli is one of

the few builders to use the distance from the head of the femur to the

floor (in bare feet) as the principle measurement in frame design. This

measurement is used instead of inseam measurement since it eliminates

any inaccuracy caused by fat or muscle covering the pelvic bone. Depending

on the body proportions of the individual, a basic guide for proper frame

sizing is to subtract 32 to 34 cm. from the distance between the head

of the femur and the floor. For instance, if the measurement from the

femur to the floor is 93 cm., the correct size frame is between 59 to

61 cm.

All three main parts of the frame (the fork, the main triangle, and the rearstays) must work harmoniously and have similar properties of elasticity. When referring to elasticity in this con text, Cinelli does not limit the term to flexibility. He includes the absorption of road vibrations by the entire frameset rather than by a specific part of a certain tube. The harmonious balance of the frameset is important because it contributes to the handling, longevity, and overall strength of the bicycle.

Cino believes that his fully sloping fork crown should be used only on relatively smooth surfaces. When using the fully sloping crown on the pave, it will transmit a lot of frontal vibrations and adversely affect the rider. The rider will be forced into directing all his energies to keeping the bicycle going in the right direction and too much of his energy will dissipate as his body acts as a shock absorber. To compensate for the extreme stiffness of the Cinelli fully sloping crown, some builders increase the rake of the forks. Cino thinks this is inadvisable since a longer fork blade adversely affects stability. If a frame is to be used on predominantly smooth roads, a semi-sloping or fully sloping fork crown should be used. A flat or semi-sloping crown is recommended for rougher roads, since both these fork crowns will be able to better absorb road shock than the fully sloping crown.

The bicycles that Cino manufactured in 1947 have changed little in the past 30 years. Although minor improvements have been made, no major revisions have taken place. The head lugs are stamped steel, but the seat lug, bottom bracket, and the fork crown are castings. The frame angles have not been changed even though many other manufacturers have followed trends to build frames with steeper angles. Although all Cinelli frames are custom-built to precisely fit an individual rider's physique, the majority of the frames are built within definite parameters. These parameters represent the limits at which Cinelli feels a bicycle's performance and handling are not hindered. Generally, frames are built anywhere from 49 to 70 cm. Top tube length varies from 51 cm. on the 49-cm. frame, to 59 cm. on the 70-cm. frame. The seat angle seems to be an important consideration since it is the only angle that is consistent in every case. Seat angles on Cinelli frames vary from 71.3 degrees for six-day frames to 74.3 degrees for criterium road frames and track sprint frames. In 30 years, Cino has never been swayed by fads. He does believe, however, that "the bicycles that are produced now are good bicycles but they are the wrong bicycles for the good roads we have today." Cino believes that a new bicycle design is needed as the cobbled and bricked roads are being replaced by smoothly surfaced roads. His new design includes steeper angles, but he believes the design must incorporate smaller-diameter wheels to accommodate the steeper angles. Since the position of the rider must be altered, it is necessary to incorporate certain changes that will give the rider optimum efficiency. This is done by providing longer cranks (about 180 to 185 mm.) and raising the bottom bracket height. This, however, must all be designed to conform with Cino's smaller-diameter wheels, smaller rear triangles, and shorter forks. The reduction of the size of the components will, in simplest terms, increase the rigidity, aerodynamic efficiency, and stability of the modern bicycle.

According to Cino, the wheel size that riders are presently using was developed to traverse cobblestones. Smaller-diameter wheels were found to fall between the cobbles, created vibration problems, and tended to break easily. Large-diameter wheels (like the old high-wheelers) were unstable and aerodynamically inefficient. As the cobbled roads in Europe disappear, a small wheel becomes an advantage for several reasons: decreased wind resistance, decreased rolling resistance, increased strength and rigidity. Figure 14-3: The new, redesigned (and very expensive) Cinelli handlebar stem. The new design eliminates the traditional front bolt for tightening the handlebar. The removal of the bolt results in improved aerodynamics.

Cino believes that the optimum size of the wheel is approximately 26 inches (66.7 centimeters) and to prove his theories he has had special lightweight rims and tubular tires manufactured for his prototypes. As a result of the increased strength gained through the reduced spoke length, he has had special narrow hubs manufactured to further decrease wind resistance.

The new Cinelli frame is designed for the smoother road surfaces and the higher racing speeds of today. In 1925, the average speed maintained in a race was about 25 to 30 kph (15.5 to 18.6 mph). Now it's very common to maintain an average speed of 45 kph (27.9 mph). In order to continue to increase this average, Cino believes that bicycles require steeper angles, higher bottom brackets, revised positioning of the rider, longer crankarms, and smaller wheels. Cino has already built several prototypes that have undergone rigorous testing in Rome where various groups are evaluating the benefits of the bicycle on the performance of individual riders.

One of Cino's first prototypes was ridden by Ole Ritter in Mexico when he broke the hour record in 1968. The bike had the longer crankarms, special Campagnolo hubs (2 cm. narrower), special-size Clement tires and Nisi rims, and a special Cinelli fork (winged-shaped fork blades on top and rounded at the bottom).

Although this new Cinelli design may someday be the norm, it will be some time before we see it on the road since it requires retooling by some of the major component manufacturers.

Cino Cinelli is a master frame builder who is unique in his innovative ideas. His most important asset is his ability to translate a rider's physical limitations into a frame that maximizes his strengths and minimizes his weaknesses. Every motion that a rider makes has been studied by Cino in order to extract useful information to incorporate in designing his framesets and parts.

He constantly experiments and uses the advice of sports physicians, trainers, and engineers to develop his new products. Cino has devoted his lifetime to the sport he loves and he, and his products, are highly regarded throughout the world.

In Italy the name of Cinelli rings of magic. In the Italian cycling community, Cino Cinelli is considered the chief hierarch of racing bicycle builders. His advice is sought after by many other frame builders who lack the training to understand technical effects of changing their designs because of style.

The Italian bicycle racers, in particular, have a special fond ness for Cino Cinelli. This relationship has developed beginning with his friendships with Cino Bartali and Fausto Coppi. The highly respected trio organized the Italian Professional Cycling Association for professional riders. The intent of the organization was to educate the riders of their rights and to represent their interests in the Italian Bicycling Federation as well as the Italian Sports Federation. Cino was president of the association for 24 years.

Finally, the book which most racers refer to as their "bible," the CO.N.I. Cycling book, is based on many of Cino's ideas. It is a compilation of the wealth of ideas and experiences of Cinelli, and two highly respected Italian coaches, Rimedio and Costa.