1. SERVICES AND CARGO MOVEMENT

In freight railway transportation, there are differences in the provided services which can be attributed to the variety of customer demands and, most importantly, to the volume and type of the transported cargo.

The provided services fall into the following categories:

- • Less-than-wagonload services

- • Wagonload services

- • Services of combined transportation

- • Services of heavy haul transport

- • Special services

The less-than-wagonload services, also termed as part-load traffic, LCL (less-than- carload), LTL (less-than-truckload) concern the transport of small packages under very strict time conditions and can be characterized as high-speed freight services (e.g., TGV postal high-speed trains). In the provided rail freight services are also included the transportation of small containers, pallets and other forms of cargos that do not make up a full wagon, under given conditions.

Wagonload services are distinguished in single wagonload (SWL) services and in train load services (TL).

SWL services involve cargo movements using single wagon trains. In these traditional freight services, the wagons (each wagon containing loads of single or multiple shipper(s)/ consignee(s)) start their journey from different origin points or end their journey at different destinations which necessitates that they pass through intermediary marshalling yards:

• Unit trains also termed full trains: These trains are formed of full wagons which start from the same origin and travel to the same destination. These trains make full use of the tractive power of the locomotives. They do not stop at marshalling yards and they run between two specific terminal stations. They have one shipper, one consignee, and one bill of lading and serve more than one final receivers.

• Block trains*: Like unit trains, block trains run between two specific terminal stations without stopping at any marshalling yard. Their difference lies in the fact that they do not use all the power of their traction units while hauling.

• Exclusive trains*: They are unit trains or block trains that serve a single final receiver.

* The nomenclature varies. Block trains and exclusive trains are also usually termed 'unit trains'.

The wagons' assembling process in marshalling yards is time-consuming and costly; hence during the scheduling of the transported freight distribution, particular concern is given so that most wagons are not subjected to the process of sorting more than once, or twice at most.

Combined train transportation covers a wide range of services . Heavy haul transportation services use wagons of high transport capacity forming trains with axle load of Q = 25-50 t.

Special services involve dedicated connections between mines and ports or mines and factories. The railway operates on a continuous basis ensuring a constant load flow, while special wagons are often used for transportation. A 'door-to-door' delivery can also be considered as a special service, since the railway company undertakes receiving and delivering products from/to the user's 'door'.

2. SERVICE LEVEL OF FREIGHT RAILWAY TRANSPORT: QUALITY PARAMETERS

The level of service provided by freight railway transportation is evaluated according to the following quality parameters:

• Tariffs

• Service frequency

• Punctuality in the delivery of goods and regularity of itineraries

• Transport possibilities provided by the railway system (e.g., capability of transporting goods of large quantities, and bulk products)

• Facilities offered at freight stations (e.g., storage area, and appropriate equipment for loading and unloading)

• Flexibility and quick response to customer demands

• Insurance during the transportation of goods (against theft, damage)

• Monitoring of cargo during its movement

• Special services provision (transport of dangerous goods, combined transport, and specialized cargo transport)

Additional quality parameters for international freight railway transport are given below:

• Short delays at border stations

• Ensuring interoperability

Some of the main features that characterize freight railway transport are:

• Length of trains: In Europe, the length of trains can reach up to 750 m. In the United States, trains used for the transportation of conventional loads are larger (up to 2 km), whereas in dedicated mine railways, their length can reach up to 4 km for heavy haul rail transport.

• Weight of trains: Trains routed in Europe usually weigh around 1,500-2,000t. Only three countries, namely Russia, Sweden and Norway, operate trains of 5,000t. The maximum train weight of heavy haul rail transport worldwide reaches up to 34,000t.

Both weight and length are important productivity factors for the railway freight industry and are influenced by various features of the system.

The permissible length is dictated by station length and by the design of the brake system. On the other hand, the features of the brake system and the design of the coupling equipment affect the permissible weight.

The adoption of the automatic coupler (Janney/Knuckle coupler in North America and China, Willison/SA3 in former the USSR) allowed for heavier and longer trains while the continued use of the screw coupler in Europe lead to shorter/lighter trains and thus less economical service provision.

• Maximum train running speed: It ranges between Vmax = 100 and 120 km/h. The heavy haul rail transport requires lower running speeds (Vmax = 80-100 km/h).

• Axle load: For the transportation of conventional loads, the maximum permissible axle load on normal gauge tracks is Q = 22.5 t, whereas for the transportation of heavy loads, it is Q = 25-40 t.

• Longitudinal gradient: Operation is highly influenced by the longitudinal gradient of the track. Gradients that exceed 1.6% result in a restriction of the train's maximum weight and speed while they also increase in the requirements for the rolling stock (available power, braking performance, etc.).

• Reliability and regularity of services: The acceptable delay time of a freight train depends on the length of the route. One could consider the acceptable delay time to be equal to 1 h per 500 km of length. Punctuality, in other words, minimization of delays, constitutes one of the parameters that determines the level of quality that a railway system provides.

• Terminal layout: Freight transport requires stations to be equipped with special facilities for collecting and handling goods. The average distance between small marshal ling yards in Germany is around 160-200 km, between medium marshalling yards 800-1,200 km and between large marshalling yards 3,000-3,500 km.

3. SCHEDULING OF FREIGHT TRAIN SERVICES

Contrary to passenger railway services, freight railway services do not usually provide their customers with regular timetables.

The common practice is to provide certain routes in the form of reserved 'paths' which are performed only when there is sufficient load.

Another common practice is that there are no predetermined routes and the trains depart as soon as the load reaches a certain target (e.g., departure as soon as 1,500 t or 100 wagons are gathered). This is practiced by the American railway network. Adjusting and scheduling of services takes place ad hoc on an everyday basis.

However, there is a trend to apply regular services similar to those of passenger trains.

The paths are used with or without sufficient cargo and the customers' cargo is shipped with the first available train, the main objective being to increase the transportation speed and the reliability of the railway system.

4. COMBINED TRANSPORT

The container revolutionized freight transport since it allows for easy transfers among all modes of transportation. At the same time, other techniques have been developed, allowing the transportation of cargo from one transport mode to another without handling the cargo itself. The common feature of all these techniques is the use of more than one transport modes in an attempt to make use of the unique advantages of each one of them. This is what characterizes this type of transportation as combined transport.

FIG. 1 Multimodal transport - train loading in ship, Sassnitz hafen,

Germany.

The potential combinations of various techniques and transport modes are usually grouped into three categories:

• Multimodal transport: Transportation is achieved with more than one modes. More precisely, one mode uses the other on a common route (i.e. one mode is loaded on the other, FIG. 1).

• Intermodal transport: The major part of transportation takes place on a ship, whereas distribution/collection of the cargo in ports continues with other transport modes.

• Combined transport: The major part of transportation takes place on either railway or barge and collection/distribution continues on the road.

Usually the term combined covers all categories, whereas the American term intermodal covers train/truck transportation. However, in the European Union (EU), the term combined transport refers to the transit of a trailer or semi-trailer truck (with or without tractor), a swap body or a container, using road transportation for the initial or final part of the route and ships, barges or railways for the main part of the route.

The EU has made great attempts to achieve an unimpeded and economically viable transportation of passengers and cargo throughout Europe at the least possible external costs (accidents, pollution, and traffic congestion). The combined transport technique perfectly responds to this policy. The 'door-to-door' cargo transfer can combine different means of transportation: flexible road transport for collection/distribution and - friendly to the environment - sea, inland water and rail transport for the main transportation.

Aside from the above-mentioned trend, the EU is also facing the issue of alpine crossings. Switzerland and Austria pose restrictions to the passage of lorries from their land, either with general restrictions (restriction of trucks weighing more than 28 t) or with technical or economic barriers (tolls imposed according to the technology of the vehicle.

[emissions, sound pollution, and suspensions friendly to the road surface] restrictions in permits).

FIG. 2 Swap-body loading to a railway wagon, Malmo, Sweden.

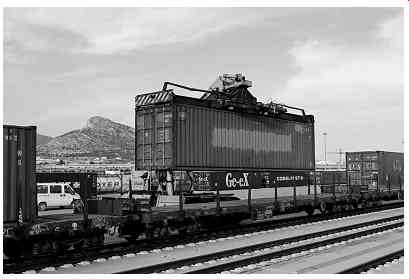

FIG. 3 Container loading to a railway wagon, Thriasio, Greece.

FIG. 4 Piggyback rail transport, Gavle, Sweden.

FIG. 5 Technique of rolling highway transport (ROLA), Bockstein, Austria.

============

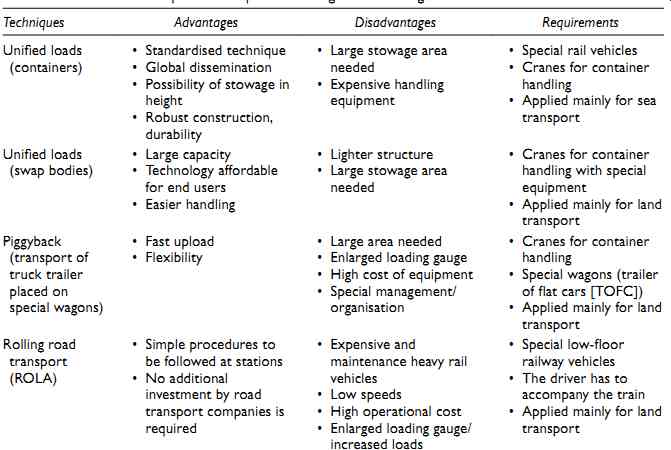

Table 1 Combined transport techniques: Advantages/disadvantages

-- Techniques:

Unified loads (containers); Unified loads (swap bodies); Piggyback (transport of truck trailer placed on special wagons); Rolling road transport (ROLA)

---

Advantages:

• Standardized technique

• Global dissemination

• Possibility of stowage in height

• Robust construction, durability

• Large capacity

• Technology affordable for end users

• Easier handling

• Fast upload

• Flexibility

• Simple procedures to be followed at stations

• No additional investment by road transport companies is required

------

Disadvantages:

• Large stowage area needed

• Expensive handling equipment

• Lighter structure

• Large stowage area needed

• Large area needed

• Enlarged loading gauge

• High cost of equipment

• Special management/ organization

• Expensive and maintenance heavy rail vehicles

• Low speeds

• High operational cost

• Enlarged loading gauge/ increased loads

---------

Requirements:

• Special rail vehicles

• Cranes for container handling

• Applied mainly for sea transport

• Cranes for container handling with special equipment

• Applied mainly for land transport

• Cranes for container handling

• Special wagons (trailer of flat cars [TOFC])

• Applied mainly for land transport

• Special low-floor railway vehicles

• The driver has to accompany the train

• Applied mainly for land transport

=============

Generally these policies aim to promote the use of railways for long-distance transport.

Combined transport constitutes a growing market for American railways since road trans port is the country's third best customer after coal mines and power stations. In Europe, though railways receive a great financial aid, their financial return is not very promising. In reality, although a significant part of the European rail freight transport is being handled with combined transport, revenue remains low.

Railways can offer four different 'products' of combined transport:

• Transport of unified load is the transport of containers and swap bodies with flat railway vehicles - platforms. Containers are mostly used for sea transport while swap bodies tend to be used for train-truck transport (Figures 2 and 3).

• Piggyback transport is the transport of a road trailer placed on special wagons - plat forms without its tractor unit and its driver ( FIG. 4).

• Rolling road or rolling highway transport (Rollende Landstraße-ROLA): This is the transport of a whole truck on special flat, low-floor railway vehicles. The driver accompanies its truck on a special sleeping car, which is included in the train formation (FIG. 5).

• Roadrailer technique is the technique in which railway bogies are adjusted on the basis of special road trailers (with their rubber-tire wheels) which can be hauled like railway wagons. It is the least common technique in Eurasia.

Table 1 presents the advantages and disadvantages as well as the technical and operational requirements of the above techniques.

5. MASS TRANSPORT

The term 'mass transportation' is used to describe:

• The transport of large quantities

• The long-distance transportation

• The high-speed transportation

• The transportation with modes of great transportation capacity

• The transportation with transport means of high occupancy

The policy of mass transport somehow justifies the role of transhippers since they can achieve 'economies of scale' for a specific transfer. On the other hand, the additional profit obtained by transshipments allows consignors and consignees to pay a smaller fare for their cargo to be transported. Finally, the 'small' customers who fail to gather large loads can also join in mass transport, thus reducing the cost of transferring their cargo.

According to the above, consignees, consignors and shippers have common interests in this policy of mass transportation. As a result, research have been conducted and money has been invested on means of transportation, techniques and equipment suitable for massification of flows. This has resulted in the development of:

• Container ships

• Cargo planes

• Road trucks of heavy tonnage

• Special trains for moving cargo (unit trains, block trains)

• Automated marshalling yards

The railway is a suitable means for mass transportation. According to the volume of load it carries, the railway adopts different solutions in order to respond more successfully to the policy of mass transport (FIG. 6).

More precisely:

a. When freight units are too big, cargo movement is performed with unit trains or block trains which are not passing through marshalling yards. For this purpose, special sidings are used to connect the railway line with the production centers or the production centers are installed/set up very close to the line.

b. When freight units are relatively big, expediting is done with single wagon trains that move at high running speeds (Vmax = 120 km/h) while their delay in marshalling yards is the least possible (automatic marshalling yards).

c. Finally, in the case of medium- and small-size freight units (5-10t) expediting is done with single wagon trains but the service level is low.

Nowadays consignors and consignees have three main demands:

• Immediate order delivery, which requires frequent and flexible services

• 'Stock' reduction; this implies that only the ordered products will be produced

• A wide variety of every product

To address these demands, the following four solutions are used today in the field of freight railway transport:

• Warehouses (platforms)

• Multifunctional railway stations

• Freight transport villages

• Combined transport

Warehouses ensure mass transportation for small loads and also reduce the transportation cost for both shippers and consignors. After the cargo has been gathered in a specific place, it is then channeled to various nearby destinations by means of small trucks thus responding to the deadlines of product delivery. This process within the chain of transportation improves the service level and reduces the 'logistic cost'.

Freight transport villages are designated areas where all activities regarding transport logistics and distribution of goods are performed by various handlers. Their operation supports the transport of goods especially in big urban centers. Freight transport villages connect different ways of transport, give access to transport corridors and offer telematics services. Their main goal is to relieve big urban centers of the traffic congestion caused by trucks. The companies related to the freight transport villages have offices in these centers equipped with modern advanced technologies, providing customers with a number of facilities.

========

FIG. 6 Mass transportation and railways. Feasible operational alternatives.

Mass transport and railways; Large transport capacity; Massification of transport; Unit trains block trains Ability for train; Low rolling; Increased speeds resistance; Technological developments formation; Train formation by single wagons; Marshalling yards; Fast response at marshalling yards Vmax = 120 km/h Medium sized freight units (5-10 t) Large freight units Yes; Yes; Very large freight units; Special branches sidings - installation of production and distribution units in close proximity to the rail track

=========

Railways now tend to organize a hub-and-spoke system in order to rationalize both the unit/block train product and the single wagonload traffic.

The concept is to establish a network of:

• Marshalling yards (the hubs of the system)

• Satellite freight stations and freight villages near these stations

• Smaller freight stations between the marshalling yards which can provide adequate cargo to justify the costs of wagon shunting

Between the hubs run mainly unit or block trains. Only limited number of trains perform pick or leave wagons at intermediate stations.

The trains are marshaled at the yards and arranged into groups for the satellite stations, freight villages or sidings.

The aim is to utilize the maximum available capacity of a train path (in terms of tractive power, length and weight) between the marshalling yards and to reduce the delay times at intermediate stations.

6. TRANSPORTATION OF DANGEROUS GOODS

The term 'dangerous goods' covers materials and objects, the transportation of which is allowed only under certain conditions. These loads are categorized according to their physical and chemical properties. Fluid and solid fuel, gas, explosives, nuclear material, polluting and corrosive materials are considered as dangerous loads.

Transportation of the aforementioned loads is done with various specialized wagons (e.g., tank wagons, closed vehicles and open and side dump vehicles with high walls).

Cargo shipments are done with unit and block trains and combined transport techniques.

Dangerous cargo transport differs from other freight activities in the following:

• Procedures of product identification and completion of consignment

• Wagon loading and unloading

• Regulations for dangerous load trains parked in high-risk areas

• Signage of wagons

• Design and method of storage/packaging

• Emergency response

• Procedures for train shunting, train formation and braking

• Cleaning of empty wagons

Activities related to transporting these products are legally established by international conventions and are conducted under strictly defined conditions of safety. The regulations applied to rail transport are COTIF/CIM/RID.

Policies of dangerous loads railway transportation must abide by the following.

6.1 Differentiation from the rest of freight transport services

Organization and execution of different activities associated with the transportation of dangerous loads should be examined and treated separately from the transport of conventional (non-dangerous) loads.

6.2 Creation of safe transport conditions

In case of an accident the extent of damage can be relatively higher than that caused by any other modes of transportation, because of the massification of railway transport. Therefore, prevention of any incident is of the utmost importance.

In this context, it is required that:

• The condition of track superstructure used is really good (to avoid derailment).

• There is a special maintenance program and testing of the rolling stock (to avoid derailment, material leakage, etc.).

• The maintenance and repairing area of vehicles transporting dangerous goods is different from that of the conventional wagons; special instructions for the repairing of vehicles are made and special areas are provided for cleaning empty tanks (to avoid explosions, fainting and fumes).

• Reception and distribution tracks specifically assigned to trains transporting dangerous goods are equipped with proper fencing, lighting, fire extinguishing and sewage systems (protection of high-risk areas).

• Modern technologies are applied for the monitoring of loads during the whole route (for immediate intervention and effective treatment).

6.3 Special measures to protect the environment

An accidental leakage of the vehicle tanks or the transported goods' packages, or even the maltreatment of the material throughout the loading and unloading-transfer phase, involves a high risk of polluting the environment due to the nature of these products. Measures taken for accident prevention also ensure the safety and protection of the environment. However, there are additional measures, aiming exclusively at the protection of the environment. These are:

• The drainage system of waste at cleaning stations of empty tanks

• The special design of the superstructure (e.g., slab track instead of ballasted track) at points of shunting tracks used by trains carrying dangerous loads, aiming at the protection of the groundwater in case of leakage

Prev. | Next

Top of Page | Article Index