On a weed-grown spur behind the shop, or at the far end of the yard, sits a railroad’s oldest and least-used rolling stock. Their builder plates read 1907 or 1916 or 1920, and they are 20 years older than the newest steam locomotive the railroad owned—a locomotive that was cut up for scrap more than 40 years ago. What are these antiques doing on the property? Why haven’t they been hauled off for scrap years ago? These are the snowplows, waiting for that big storm that shuts down the railroad, or waiting to clear that lightly used branch that has sat idly for weeks during the winter. On some lines a plow may wait out the whole winter without turning a wheel, while on others, a plow might see weekly or even daily service to clear the line.

Wedge Plows

Light snow can be easily cleared from the tracks by small pilot plows permanently fixed to the locomotives. But when an arctic storm or nor’easter blows through, and snow is measured in feet rather than inches, the railroad drags out its ancient plows and sends them out on the line. One of the most common styles of big railway snowplows was the “wedge plow.” This descriptively named machine is exactly what it sounds like: a wedge-shaped plow. It is essentially a huge knife blade that is pushed along at speed, forcing accumulated snow off the tracks.

![]()

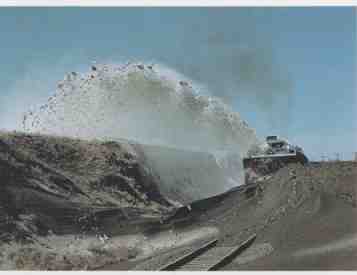

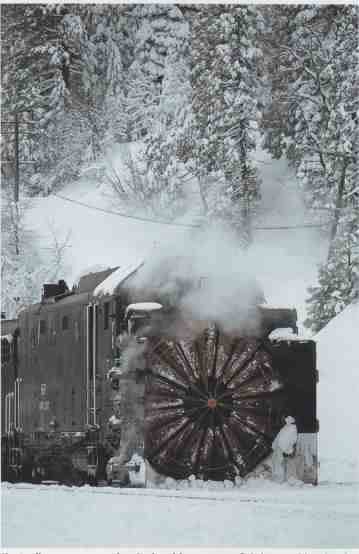

ABOVE: A Southern Pacific rotary plow clears snow from the eastbound

tracks at Yuba Pass, California. The rotary is among the most amazing machines

on the rails today, although their high cost of operation means that they

are all too rarely seen in action.

ABOVE: A Canadian Pacific plow clears the Lyndonville Subdivision

at Barton, Vermont. Northern Vermont is notorious for its tough winter

weather, as arctic storms blow down from Canada and dump lots of snow.

This makes for good skiing, but difficult railroading.

A typical type of wedge plow that is still in use is the Russell plow, built after World War I. This steel-framed ma chine features a Spartan wooden interior, an adjustable front blade or tongue, adjustable side-mounted wings, and a raised cupola for the plowmen to ride in. The plow is heavily weighted to minimize the likelihood of derailment when it is being shoved along through drifting snow at speeds up to 50 miles per hour. It’s a fairly simple machine with minimal complicated equipment. A long air-actuated cylinder rides near the floor of the plow to raise and lower the front blade. Additional cylinders operate the hinged wings, which are used to give the plow additional covering power. These air-powered cylinders are essentially larger versions of the standard air-brake cylinders found on most conventional railway equipment, but instead of applying pressure to brake shoes, they move the tongue and wings. An auxiliary air reservoir fed by the main air-brake line serves these cylinders, which are controlled by the crew operating valves in the cupola. The crew monitors two gauges, one for the brake line and one for the auxiliary reservoir. Except for these basic controls, the cupola features few amenities.

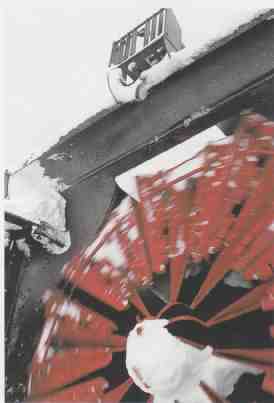

ABOVE: A seemingly permanent fixture of the rail yard, a snowplow will

sit immobile for months, sometimes years, waiting for the call to action.

The plow is often the oldest piece of equipment on a railroad’s roster.

This classic, built by the Russell Snow Plow Co. of Ridgway, Pennsylvania,

is owned by the Wisconsin Central.

The wedge plow is shoved along by conventional locomotives. On lines only lightly covered with snow, just one locomotive might be as signed to the plow, but in areas of heavy snow, it would be common to find two or three locomotives shoving a wedge plow. In the nineteenth century, as many as six to eight steam locomotives were assigned to Central Pacific’s old Bucker snowplows working Donner Pass. The presence of the snowplow riding ahead of the locomotive, combined with the blinding effects of blowing and swirling snow, produces an awkward arrangement, as the engine crew shoving the plow can not see where they are going. Instead, they must rely on the plow crew riding in the cupola to pi lot them. The plow crew and the engine crew communicate as best they can. Traditionally this was done with whistle signals, but today they normally communicate on two-way radios, using whistle signals only in extreme circumstances.

As the plow races along, slicing through snow, shoving it forcefully to either side of the tracks, the crew has to raise and lower the tongue and adjust the wings to clear obstructions on the line. The tongue must be lifted at highway grade crossings, track turnouts, and railway level crossings. Failure to lift the tongue at the appropriate time could cause the plow to derail and result in serious damage to the tracks and crossings. Rail ways mark all known obstructions along the line with clear warning signs that can be easily spotted in heavy snow. Different railways use a variety of different marking standards, and many types of signs or posts have been employed over the years.

Operating a snowplow requires great skill and nerves of steel. A plow crew has to be ready to take a call at any hour of the day in the very worst weather and, once called, must battle the elements for hours at a time. Plowmen must have detailed familiarity with the railway line they are working, knowing it backward, forward, and in side out. A stretch of track that you worked on all summer long looks very different when covered by several feet of blowing, drifting snow. With as much as 4,000 horsepower propelling you for ward at up to 50 miles per hour, losing track of where you are can prove fatal. A single obstruction can easily derail the plow. At times, the snow can get too deep, such as in cuts where it accumulates and drifts, or on mountainsides, where slides and avalanches can dump tons of snow on the tracks. This can cause a plow to bog down and stall. In most situations, the crew can back out and make a second run toward the obstruction, slamming into it with great force. It may take several runs to clear larger drifts.

Sometimes the plow derails. This can be very serious if the plow rolls over, but usually it’s just inconvenient. Plowmen expect the inevitable derailment, and they typically carry a host of tools, such as re-railing “frogs,” chains, jacks, and wrenches to assist with getting the plow back on the rails. Plowing is a dangerous job, but without the plows, the railway would shut down. Seeing a plow at work is like watching a rolling avalanche racing along, creating a storm of snow exploding forward as it clears the tracks, freeing the railway of its icy shackles.

Rotary Plows

The most significant nineteenth-century innovation in snow removal was the rotary snow plow. Wedge plows and locomotive pilot plows were adequate for clearing tracks in the East, where relatively moderate snowfall seasonally interrupted service. But as railways pushed west-ward across North America, crossing the Great Plains and surmounting high mountain passes where fantastic snow depths are common, these conventional plows proved lacking. The wedge plow—an effective tool for fighting small drifts and relatively light snow—suffers when put to the test in deep mountain snow. It is especially poor at clearing steeply graded lines, as the wedge plow needs to be shoved along at speed to be most effective. The railroads needed a way to combat the deep snow of mountain passes and quickly conquer snow slides and blockages.

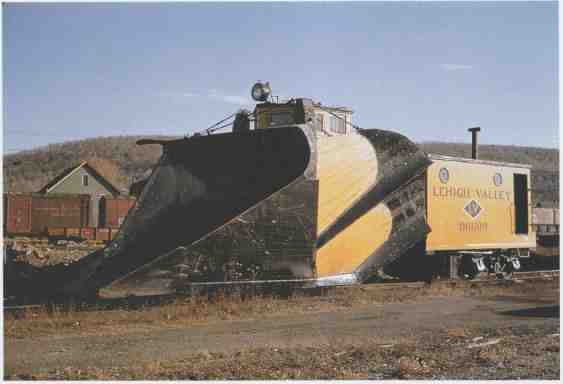

ABOVE: This Lehigh Valley snowplow dates from an era when even the most

utilitarian equipment was designed to look nice. Notice the wooden construction

of the sides and wings. It was photographed on a snowless December day

in 1971 at the Lehigh Valley yards at Sayre, Pennsylvania.

On high western mountain passes, men waged war against nature, fighting to keep the tracks open in all weather. This was more than simply a matter of convenience at times it was a matter of survival. In those days the railroad served as the lifeline to remote western communities, and without transportation, people were at risk of being cut off from civilization. Severe storms could shut down railways for days at a time. Railroads would employ every tool at their disposal to clear the line, often sending armies of men with snow shovels to dig through drifts and deep cuts clogged with snow.

The rotary plow was perfected during the mid-1880s, just in time to cope with some of the worst winter storms ever encountered: the terrible blizzards of 1887—1888, which remain legend to this day. The rotary is an amazing machine that was the brainchild of Canadian inventor Orange Jull. It was a tool whose time had come, and it arrived on the scene at just the right time. Jull de rived his rotary plow from an earlier paddle plow designed by J. W. Eliot. Jull’s prototype incorporated a pair of rotating fanlike blades spinning in opposite directions and powered by a stationary steam engine. The first set of blades fed snow into the plow, while the second set propelled the snow out through a chute.

Jull sold the manufacturing rights to his friends John and Edward Leslie. During the winter of 1883 and 1884, a prototype was constructed in Canada with the aid of the Canadian Pacific Rail way. It was tested in the spring of 1884 and proved successful, generating some interest among the railways. The plow wasn’t ready for general use, however, and over the next few years the Leslies refined Jull’s design, implementing several significant improvements, and they went into business contracting the manufacturing of rotary plows. The Leslies did not actually assemble the rotary plows, and most were built at established locomotive manufacturing plants. Among the Leslies’ improvements was a single simplified rotating fan that used a system of self-adjusting bladed cones to scoop and throw the snow. This was far more efficient than Jull’s original double fan system. The Leslie fan was capable of moving more snow in less time, and it was less prone to breakdowns. They also added a reversible snow chute, which permitted snow to be directed to either side of the tracks. Lateral adjustable blades were employed to give the plow greater range by scooping snow from the sides of the tracks into the plow blades. Adjustable blades for ice cutting and flanging were used to minimize derailments and keep flangeways clear after the rotary fan had cleared most of the heavy snow. By the 1890s, the basic steam rotary design had reached its common form. Later design improvements were a function of size, more modern construction materials, and finally the conversion of some plows to diesel- electric operation.

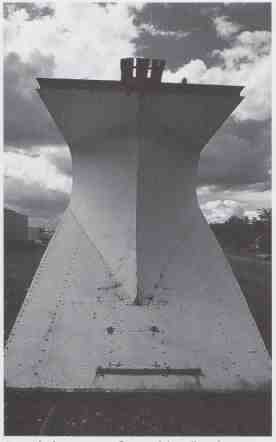

ABOVE:This unusual-looking plow was built by the Boston & Maine

in 1895. Photographed at the B&M yard in Northampton, Massachusetts,

on April 9, 1934, it was stationed at East Deerfield the following winter,

where it was assigned plowing duties north on the Connecticut River Line

to East Northfield and on the Ashuelot and Turners Falls branches.

ABOVE: This double-track plow represents a different style of Boston & Maine

plow. Like all plows from the period, it had no propulsion of its own and

was shoved along by a steam locomotive. Built in Concord, New Hampshire,

in 1904, this plow was stationed in the Boston area. It was photographed

at B&M’s Salem yard on January 26, 1936.

The Leslies were extremely successful with their snowplow enterprise, and sold many plows within just a few years. At first the western rail roads were most interested in the rotary. The first 10 plows were all purchased by western lines and were quickly dispatched to clear the most difficult mountain passes. The Union Pacific, Northern Pacific, Central Pacific, and Canadian Pacific all employed early rotaries, using them in the Blue Mountains of Oregon, Stampede Pass in Washington, over the California Sierra, and in the Canadian Rockies. Midwestern and snow-plagued eastern lines bought rotaries too, and the plow was eventually sold to railways around the world.

A rotary plow is an ominous looking ma chine, its great fan appearing like an enormous gaping mouth. A traditional rotary plow fan is powered by a stationary onboard reciprocating steam engine that operates on the same principle as the steam locomotive engine, using a firebox, boiler, and cylinders, except the engine is used strictly to turn the fan blades. (As explained earlier, the rotary is not a self-propelled machine and requires a conventional locomotive to push it along.) The steam engine turns a shaft, which is connected to beveled gears that turn the fan. The fan can rotate up to a maximum of 200 to 400 rpm, but normally works at approximately 90 rpm when blowing snow. The fan consists of conical scoops arranged in a hub and spoke network.

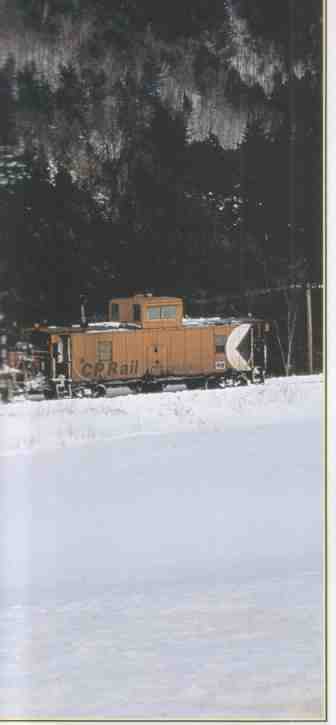

ABOVE: A Canadian Pacific plow train works at Wells River, Vermont,

in March 1993. At one time a common sight in winter, these trains are becoming

increasingly rare. Changes in railroading have led to far fewer branch

lines, as well as more modern machinery and different service priorities.

Each cone is fitted with self-adjusting hinged blades designed to feed snow into the cone as the plow moves along. The rapidly spinning conical blades scoop snow and by natural centrifugal forces thrust it out through the chute at the top of the plow. This system is especially efficient for rapidly clearing heavy wet snow, the variety commonly dumped in the western mountains.

The steam-powered rotary required a mini mum of three men to operate it: an engineer and fireman to keep the engine running, and a pilot to guide the locomotive crew pushing the plow from behind. As in the case of a wedge plow, the loco motive crew pushing the plow is running blind, relying on the pilot’s signals—traditionally a sys tem of long and short whistles—to guide them. On mountainous lines, where grades exceed two percent and snow depth might be greater than 10 feet, it was not unusual for several steam locomotives to push a single rotary.

ABOVE: The spinning blades of a rotary are designed to draw snow into

the plow and blow it far from the tracks. Rotary plows are excellent tools

for moving lots of wet heavy snow, which is why they are still used up

on Donner Pass.

The rotary plows were built in a variety of sizes. An early prototype was just 34 feet, 2 inches long; 12 feet, 8 inches high; and 9 feet, 6 inches wide. Its steam engine used a pair of double-acting I 7x22 (bore and stroke) cylinders to develop an estimated 700 horsepower. Later plows used fans that ranged in circumference from 9 feet to more than 12 feet. The heaviest rotary weighed 150 tons, nearly five times more than the first. Cumbres & Toltec’s former Rio Grande plows were among the smallest rotaries built. They had to accommodate the restrictive loading gauge of the Rio Grande’s narrow-gauge line. The majority of steam-powered rotaries were erected by the American Locomotive Company (Alco) or its predecessors, and eventually Alco purchased the manufacturing rights from the Leslies, after the turn of the century.

ABOVE: Union Pacific rotary plow No. 900076 clears drifts at Bennett,

Colorado, in March 1977. Diesel manufacturer Lima-Hamilton built this plow

in December 1949, one of only four Leslie rotaries manufactured by L-H.

ABOVE: A Southern Pacific flanger rests at Truckee, California, after

a tough night clearing snow on Donner Pass. SP Hangers made regular circuits

between Truckee and Fulda to keep snow from accumulating on the tracks.

Balloon tracks at both locations allow the Hangers to reverse direction

quickly without the locomotives needing to uncouple and run around.

Since the end of the steam era in the 1950s, rotaries have been largely supplanted by other, more modern snowplows a result of the change from steam to diesel technology. Steam rotaries are expensive to maintain and operate, and diesels have made other plow designs more cost- effective. Despite this, some lines have held on to rotary plows, often converting them to diesel-electric operation. The Burlington was the first American line to make such a conversion, and Southern Pacific (SP), which operated the largest fleet of Leslie rotaries, successfully converted many of its plows and greatly prolonged their life (see ‘Rotary Encounter on Donner Pass” later in the section). Conversion to diesel-electric operation entails replacing the steam engine with traction motors and other electrical components and pairing the rotary with a diesel-electric engine to provide electric power. The great cost of converting a plow notwithstanding, the rotary design is more effective when electrically powered. SP’s diesel-electric rotaries use four traction motors that generate up to 1,200 horsepower (almost twice the power of the early steam-powered prototypes) to turn the blades. Although rotaries are still used, their operation is infrequent at best, and sometimes years pass between runs.

The Cumbres & Toltec Scenic, which operates a 64-mile-long narrow-gauge line in Colorado and New Mexico (one of the last remnants of the Denver & Rio Grande Western narrow- gauge empire), still uses a steam rotary to clear its line. The western slope of Cumbres Pass is a tortuous 4 percent climb, cresting at just over 10,000 feet above sea level. As many as three 2-8-2 Mikados are required to shove the plow when clearing this line.

Jull Centrifugal Excavator

Despite the success of his rotary plow invention, Orange Jull was dissatisfied with his arrangement with the Leslie brothers. In frustration, he invented another snowplow that carried his name: the Jull Centrifugal Excavator. It used an enormous steam-powered angled auger to propel snow, in an arrangement similar to that employed today on many home-use snow blowers. While the design was effective and generated some interest among American railways, it didn’t work as well as the rotary. Jull received only a handful of orders for his Excavator. To day the Excavator is little more than an historical curiosity, whereas the Leslie rotary plow had a 60-year production run and still can be seen in use today.

Flangers and Spreaders

More common than the rotary plow for modern snow removal are flangers and spreaders. Spreaders are typically used to move moderate amounts of snow flangers keep a line open in areas of heavy snowfall. Flangers are pulled along by conventional diesel locomotives that are equipped for snow service and have electrical controls to operate the flanger blades from the locomotive cab. The flanger itself has a body somewhat narrower than that of a conventional railway car. It has two blades that can be lowered below rail level to clear snow and ice accumulation on the tracks and keep the flangeways open. Clearing the flangeway is the most important function of a flanger. The wheel flange is what guides a railway car and holds the train on the tracks, and ice-clogged flangeways can derail a train. The flanger operator can direct the snow to either the left or right side of the tracks, and raise and lower the blades to avoid obstructions in the same way that a wedge plow operator controls the plow tongue. A flanger might run at 35 to 40 miles per hour, as its effectiveness is, in part, a function of speed. While a flanger is an excellent tool for keeping a line open, if snow continues to accumulate, a railway will need to call on more powerful equipment to clear the tracks.

ABOVE: In the heavy snows near Donner Pass, Jordan Spreaders and rotary

plows work in tandem to keep the double-track lines clear. On February

22, 1993, the Jordan is working eastbound on the No. 1 track toward Soda

Springs. It dumps the snow into the path of a rotary plow, which will follow

a few minutes later on the No. 2 track.

ABOVE: Southern Pacific’s Leslie rotary plow clears the No. 2 main track

west of Soda Springs, California. Donner Pass is one of the Leslie rotary’s

last remaining stomping grounds.

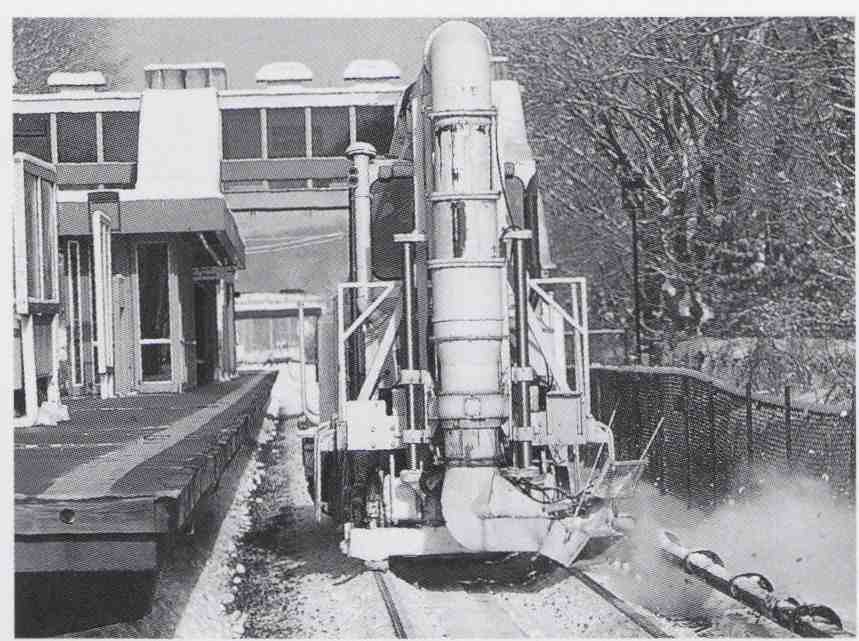

ABOVE: Electrified railroads have special plowing considerations. Metro-North

has to make sure its electric third rail is kept free of snow and ice.

On January 6, 2001, an RM-700 snow blower clears snow at Katonah, New York,

on the old New York Central Harlem Division.

---122b A Burlington Northern snow blower clears the Hoffmans Avenue interlocking

at Dayton’s Bluff in St. Paul, Minnesota, on January 19, 1994. This type

of equipment is often used to keep switches from becoming clogged with

snow and ice.

Southern Pacific routinely maintained five flanger sets at its yards in Roseville, California, to keep its extremely snowy Donner Pass crossing open. In modern times, SP powered its flanger sets with specially equipped Electro-Motive Division SD9’s or, in SP’s last years, with snow-service GP38-2s. These locomotives worked regular freight duties in the off-season. To keep the flanger sets moving and to minimize turning time and delays to trains on the mainline, SP constructed special “balloon tracks,” or loops, at key locations. SP also regularly assigned flangers to its other snowy mountain crossings, including Pengra Pass in the Oregon Cascades and Siskiyou Summit near Ashland, Oregon.

Another common snow-fighting tool is a Jordan Spreader adapted for snow service. Many railways adopted snow-service Jordans instead of relying on the more traditional railway plows such as rotaries and Russell wedge plows. The basic configuration of a Jordan Spreader, equipped with an adjustable front-end plow and large hinged wings, is well suited to heavy snow removal. The front-end plow clears the snow off the tracks and can be arranged to push the snow to either side. The Jordan’s extendable wings are used to plow snow well beyond the normal width of the tracks that the spreader is running on. This allows the Jordan to clear a double- Track mainline, or to move large amounts of snow well clear of the tracks. A Jordan is suited for diesel-electric operations, and as in the case of other traditional plow types, it can be shoved by one or more diesels in order to move heavy snow. Diesel locomotives offered a big improvement for snow plowing, since a diesel can pro duce maximum power at slow speeds, while a steam locomotive cannot.

In the 1960s, Southern Pacific ordered two specially designed spreaders for its Donner Pass route, and these are among the largest of the type. According to Dick Dorn in his December 1994 article in Trains magazine, SP’s big snow-service Jordans can move as much as 125,000 pounds of snow per second when traveling at speed with wings fully extended. The advent of these spreaders reduced SP’s reliance on its famous rotary plows, as the spreaders are fully capable of handling all but the worst snow conditions.

Today, many lines dispatch trains remotely, using computerized centralized traffic control (CTC) to authorize train movements and set switches. Union Pacific directs its trains from Omaha, Nebraska CSX from Jacksonville, Florida; and Burlington Northern Santa Fe from Fort Worth, Texas. So a dispatcher sitting in a comfortable climate-controlled dispatch center, a thousand miles from the route he’s responsible for, will be lining a route with his computer mouse, as snow slowly covers the tracks. In order to minimize the difficulties with remote-controlled switch operation, many dispatcher-controlled sidings and junctions are equipped with switch-point heaters or blowers to keep points from icing up and ensure that the switches operate properly.

Modern Snow-Fighting Machines

Railways are expected to operate 24 hours a day, regardless of weather. While the antique plows of nineteenth century design are used to clear the railway in extreme situations, many rail ways operating in snowy climates have other tools for keeping their lines clear during lighter snow fall. Even light snow clogs switch points, fouls junctions, yards, and terminals, making day-to day operations difficult, so railways rely on switch- point heaters, snow blowers, snow jets, and other equipment to keep daily operations fluid.

ABOVE: The Leslie rotary snow plow is the ultimate snow-fighting machine,

but it takes a heavy winter snow, like the one that fell on Emigrant Gap

near Donner Pass in February 1993, to bring these venerable machines out

for the job.

Some remote switch-point heaters are fitted with sophisticated snow-detection monitors that turn the heaters on and off as conditions change, while others rely on railroad workers to operate them manually. It is important to run switch heaters only when ice and snow are accumulating, and not when it’s just raining. Several companies manufacture snow-detection equipment to deal with these needs. The Rails Company sells an electro optical detection system that employs micro processor-controlled sensors to distinguish between different types of precipitation. Spectrum Infrared offers an infrared detection system.

To clear switches in yards and at junctions, railroads employ snow blowers and snow jets. Harsco’s Fairmont Tamper division builds a Typhoon snow blower designed to clear switches. This self-propelled machine uses a hydraulically powered centrifugal fan to blast air downward at speeds up to 160 miles per hour, and a heavy-duty scarifying broom. A far more powerful snow removal tool is the snow jet, which uses a jet engine to blast snow from the track. One of the pioneers of the snow jet was New York Central, which operated many of its largest yards in the Great Lakes Snow Belt where lake-effect snow can paralyze operations for days. It constructed several snow jets at its company shops in the 1960s, using surplus jet engines. The jet engine rides on a self-propelled platform powered by a small diesel engine with a hydraulic transmission. Central’s snow jet can run up to 20 miles per hour when not blowing snow, but when it is blowing snow it moves much slower. The jet thrusts hot air at 65,000 pounds down ward, blowing and melting snow. The air tempera ture ranges between 200 and 300 degrees Fahrenheit, but it is the force of the air, rather than the heat, that is primarily responsible for removing snow. Even with this great force, crews typically make at least two passes over each switch to ensure it is free of obstructing ice and snow. The snow jets have been working for more than 30 years for New York Central and its successors Penn Central, Conrail, and now CSX.

Today, many lines regularly use snow jets to clear yard switches, and they can be purchased commercially from Essco. The modern Essco Snowjet is diesel-hydraulic powered, allowing travel speeds of up to 30 miles per hour, and it features a rotating jet nozzle.

Railways also use less specialized tools for snow removal as well. Ballast regulators and bull dozers are often equipped for snow service. Al though far less spectacular, and not capable of moving the great quantities of snow of traditional plows, these modern machines require far less labor than the older plows, allowing railroads to keep winter employment costs down. Typically only one man is needed to operate a ballast regulator in snow service, compared to a crew of six for a typical Russell plow set. Still, when the big storms hit, the old plows still find their day in the snow!

---124 In the blue glow of evening on February 23, 1993, a Southern Pacific

snow-service Jordan Spreader emerges from the west portal of Tunnel 6 at

Donner Pass. The Jordan Spreader proved an effective snow removal machine

in most situations, relegating the rotary plows to only the most difficult

work.

=== === Rotary Encounter On Donner Pass === ===

A working Leslie rotary snowplow is an amazing piece of railway equipment, but it is among the most elusive. Finding one in action on a mainline is one of the greatest challenges a railway photographer can undertake. A rotary is labor-intensive and expensive to operate, and as a result it is called upon only after all other means of snow removal have been exhausted. During the early 1990s, I spent several winters photographing Southern Pacific’s rugged Donner Pass crossing in the Sierra Nevada of California—a place legendary for its heavy snowfall. But even here, in one of the last regular domains of the Leslie Rotary, drought conditions prevailed for the better part of a decade, and while heavy snow fell at times, Southern Pacific largely relied on its fleet of flangers, spreaders, and contract bulldozers to keep Donner open to traffic.

Southern Pacific’s mainline over Donner Pass was completed in 1868 by SP’s predecessor, Central Pacific, as the western portion of the original transcontinental railroad, famous for its legendary joining at Promontory, Utah, on May 10, 1869. This amazing mountain crossing is one of the most famous in American railroading. It was the vision of western railroad pioneer Theodore Judah, who personally surveyed much of the route, gathered California businessmen to raise the capital needed to build the railroad, and lobbied Congress and the resident to pass the necessary legislation—but Judah never lived to see the route completed. The railroad climbs out of the Central Valley at an elevation just above sea level to the summit of the Sierra at Donner Pass, ascending to more than 7,000 feet above sea level in just 90 miles. In so doing, the route passes directly through one of the heaviest snowfall regions in the Continental United States. In a light year, more than 200 inches of snow will fall at Donner; in a heavy one, more than 800 inches.

As California grew, traffic over Donner boomed. A second track was completed over the route in October 1925, and during World War II the railroad was handling as many as 100 moves a day. After the war, however, this once-crucial thoroughfare entered a long period of decline. By the early 1990s, though the Donner Pass crossing was still functioning as a primary mainline between California and the East, hosting a dozen freights and Amtrak’s Chicago-Oakland California Zephyr every day, it had lost its predominant role as the way west. Other railway routes were busier, and Interstate 80, which runs parallel to the railroad over Donner, became the main artery to northern California.

The long drought subsided during the winter of 1992—1993, and a wave of fierce Pacific storms pounded California, bringing badly needed rain to low areas and heavy snow to higher elevations. By early February 1993, roughly 10 feet of snow had fallen at Donner Pass, and Southern Pacific was running out of places to put it. Then a new series of storms dumped more heavy snow on the Sierra, and the conditions were set for SP to call out its Leslies.

This was my opportunity to catch the big plows in action! I carefully watched the weather, waiting for my chance. My friend and fellow photographer Brian Jennison lived at the foot of the Sierra’s east slope near Reno, Nevada. When I called him on the evening of February 21 for a status report, he replied, Hey kid, if you want the rotaries, get up here tonight. They’re already out of Roseville [ and have an early morning call out of the Gap [ Gap on Donner’s west slope] for the run over the mountain to Truckee.”

Wasting no time, I flew to Reno, where my Toyota pickup was waiting. In the early hours of February 22, I chained up my truck, donned my winter gear, and fought my way over Donner, reaching Emigrant Gap just as SP crews were preparing a set of rotaries for the trip over the mountain. Beasts of another era, the rotaries are among the last working remnants of the steam age. Though SP’s plows had long since been converted to diesel-electric operation, they still retained a steam-era appearance. Steam wisped from their blades, keeping them free of snow accumulation.

At Emigrant Gap the snow was only a few feet deep, but at Norden, near the summit, there was an accumulated snowpack about 17 feet deep. Despite a long historical precedent, this plowing of Donner was far from a routine exercise, as it had been eight years since the last rotary plow had cleared the pass. I was among several photographers that day who had dropped everything to record the event.

The rotary set consisted of two plows, each coupled to a specially converted Electro-Motive Division F7 B-unit (cabless locomotive) to power the rotary blades, with four of SP’s big Electro-Motive Division tunnel motor” diesel-electric locomotives to propel the plows over the mountain. This was two more locomotives than SP traditionally used to power its rotary plows, but the railroad was not taking any chances. Preceding the rotary-set up the mountain was one of SP’s specially designed Jordan Spreaders, which ran on the opposite track to plow snow into the path of the rotary. The rotary would follow close behind and blow the snow far from the tracks. Soon this procession of men and machines was under way and working up the mountain. I set up at Yuba Pass, a few miles from Emigrant Gap, and made my first photograph of the mighty plows in action. Over the next few days, I had numerous opportunities to catch these fantastic machines in action, and the results are displayed in this guide.

The second day of plowing began at Truckee, California. The plows had cleared the lower of the two Donner crossings the day before, but the original crossing, which followed a different alignment, had been closed to traffic as a result of the heavy snow. While the lower crossing utilized a 2-mile-long tunnel, the original line was more circuitous, employing a series of shorter tunnels and snowsheds while skirting the north face of Mt. Judah (named for the line’s surveyor). Drifts and piles of snow, some more than 10 feet deep, covered the tracks. SP hoped its legendary rotaries could reopen this difficult mountain crossing. Brian Jennison and I set out toward Truckee to intercept the rotaries on their westward run over Donner. In the winter, there is little highway access to the tracks, as most of the trails used in drier months are buried under many feet of snow. This greatly limited where we could shoot the plows from. Furthermore, our arrival at Truckee was delayed by a serious snow-related accident on 1-80; two trucks had crashed, blocking the westbound lanes for an hour. Despite these difficulties, we made it to Truckee in time to catch the plows leaving. We then drove to the summit, where we hoped to catch them clearing the Chinese Wall,” that section of track riding high on a man-made shelf cut into the rock face of Mt. Judah between two snowsheds. Plowing was very slow that day as the rotaries fought their way through Coldstream Canyon on their way up Donner Pass. We never got the shot of the rotaries crossing the Chinese Wall, because the plows derailed when they encountered an enormous drift on the closed line. Even the mightiest of snowplows are sometimes defeated. SP eventually got the line open, and the rotaries returned to Roseville, mission completed. This turned out to be the final winter for the original 1868 crossing. In the summer of 1993, cost-conscious SP discontinued operations over the older route, choosing to rely exclusively on its newer crossing.

Having witnessed a multitude of railway operations around the world, I can say with certainty that seeing SP’s rotaries in action was one of the most impressive sights in all of railroading, and definitely one of the rarest!

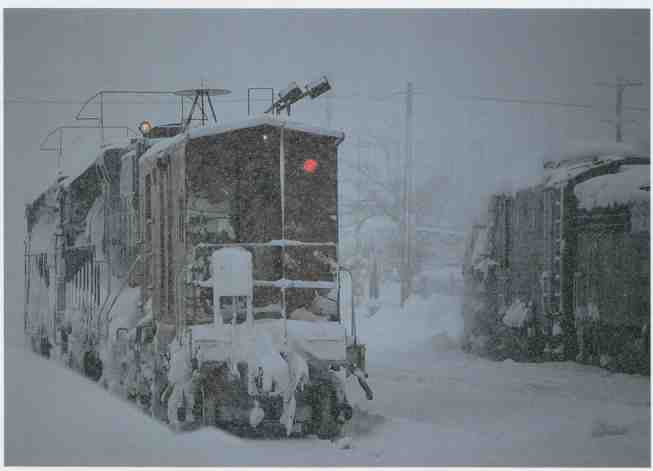

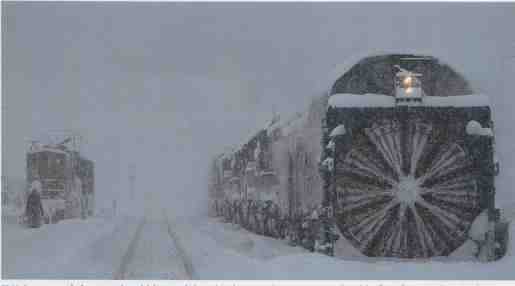

ABOVE: “We’ve scored the rotaries, kid!” exclaimed Brian Jennison on exposing

his first frame of Kodachrome at Truckee, California, in February 1993.

On the morning of February 23, after battling snarled traffic on I-80,

we finally made it to Truckee to find the rotaries in all their glory,

steaming and ready to assault the east slope of Donner Pass. It was still

snowing hard, and visibility was poor. Later in the day these plows derailed

on the No. 1 track at the summit.