The previous sections have shown how railways of today are making use of

high technology. But what about tomorrow? Where do railways go from here?

What developments can improve the already good record of railways for mass

public transport? The already substantial mileage of new railways in Europe

and elsewhere will be extended.

Already there are plans for a new line connecting

Paris, Brussels and Cologne, with a connection to the French Channel Tunnel

terminal and possibly branch to Amsterdam. There is a vision of a much wider

European high-speed network — a vision which will employ modern technology

for the trains, track, and signaling and control systems.

Already the technology of the existing French TGV trains is last generation.

The new trains for the through services to the Channel Tunnel are being

built with the latest in hi tech.

The use of on-board computers is now

regarded as normal, and there is little doubt that as microprocessors become

even more clever they will take on new and greater significance.

The Association of American Railroads provides research

and specialized test facilities at the Transportation

Test Center in Pueblo, Colorado.

Here, an Amtrak locomotive is evaluated on the roll dynamics unit. The

Colorado Test Center is able to re-create actual running conditions on

three different test tracks: 24km (15 miles) of AC-electrified track

for main-line use); 16km (10 miles) of track equipped with third-rail

DC electrification; and a light-rail-type catenary.

Developments in North America

Some people seem to think that railways in the United States have not kept up with developments in Europe. Their apparent reluctance to “advance” results from special conditions, which will be explained. This too will change. In the 1980s and 1990s, the American privately-owned freight railways were freed from many regulations that had prevented them from competing effectively with road transport. Mergers and reorganization aimed at the consumer, together with better use of existing resources, made money available for other developments. But these objectives depend critically on reliable locomotives.

During the next few years, the development of American locomotives will be heavily influenced by these issues. Manufacturers will be under severe pressure to improve reliability and maintainability, while reducing exhaust emissions without loss of efficiency. Three trends can now be identified as:

(i) the introduction of asynchronous three-phase electric traction motors;

(ii) the expanding use of microprocessors for real-time diagnostic monitoring of a locomotive’s condition;

(iii) the role of federal and state agencies in formulating regulations for exhaust emissions standards, with which manufacturers must comply.

MICROPROCESSORS

Microprocessors have been used in locomotives for a number of reasons, a major one being their diagnostic application. Maintenance departments can anticipate and cure problems before actual failure occurs if an impending fault can be identified. Faults in operating systems can be monitored and reported, together with diagnostic help for a cure. Temperatures, pressures, fuel, lubricating oil and water supplies can all be monitored.

Locomotives can be equipped with on-board computers, while displays enable data to be read direct from the microprocessors. Data can also be transferred over a communications link to a remote place (maintenance depot) for action. Most of the monitored quantities will have operating limits; exceeding these will give a fault warning. If the quantity then returns within the limits, a “fault clear” or similar indication is given. If data on “faults” and “clears” is stored in the computer’s memory, those annoying “intermittent” faults (which would otherwise go undetected) can be identified.

Locomotive operation and maintenance is being revolutionized through the microprocessor. As computers become smaller and even more powerful, advances in the design of operating systems will be a further aid to utilization and reliability.

ELECTRIC TRACTION MOTORS

Three-phase drives are now widely used in Europe, but there has been no significant application of them in North America for main-line railways. The benefits, which bear repeating here, include reduced maintenance because there are no commutators or brushes, which in turn eliminates the risk of flash-over and moisture-related earthing (grounding) problems.

North American dc motor drives are nevertheless very reliable but represent an on-going cost. Integrating the complex power electronics and computers required to control ac traction motors into the locomotive, while maintaining and even improving already high reliability — and doing so at reasonable cost — requires some courage! The decades to come will see a new breed of high-power locomotives with ac traction drives on American railways. The first of four new generation 2835kw (3800hp) SD6OMAC locomotives, developed jointly by Siemens and General Motors Locomotive Group, are already being tested on GMLC facilities. They will then go to the joint test ground of the Association of American Railroads (AAR) at Pueblo, Colorado, and subsequently entered service.

The F69PH diesel-electric high-speed locomotive for Amtrak

in the US features the latest AC three-phase technology.

MINIMIZING POLLUTION

The control of exhaust emissions is in everybody’s interest. In the United States the revisions to the 1990 Clean Air Act directed the American Environmental Protection Agency to issue new emissions regulations for new and “re-engined” locomotives. The Act allows states with problems of air pollution, such as California, to also impose limits on emissions from existing locomotives. Similar action is likely before long from the EEC.

Most of the above is not confined to the United States. Already diagnostic systems are in use in Europe, and reference has already been made to pre-journey checks by on-board computers in the chapter on high-speed trains. Even greater use of on-board computers is being made on the new breed of Trans-Manche Super Trains for the Channel Tunnel.

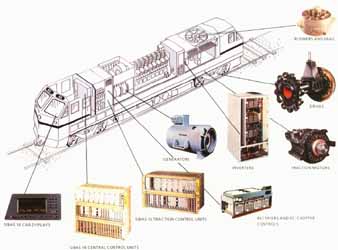

Equipment for Diesel-Electric Rolling Stock with Three-Phase

technology: Sibas 16 Central Control Units; Rectif Ers And Dc Chopper

Controls; Traction Motors; Inverters, Etc.

PASSENGER COMFORT

Railways have to compete effectively with road and air transport. To win traffic from either, they must offer something the competition does not. Very fast city-center to city-center travel has been a feature of rail for at least the last decade, and has steadily attracted more and more passengers.

Apart from speed, railways can offer very comfortable travel in relatively quiet air-conditioned vehicles. It used to be said that British railways could not justify the cost of air-conditioning because of the relatively equable climate. That may once have been true financially, but it is no longer the case because the level of sound and heat insulation now expected can be obtained only with a sealed vehicle with fixed windows and the very minimum of well-fitting doors. This requires air-conditioning.

Comfortable seating, comfortable environment, good decor and a good ride are all built into today’s vehicles. But, as we have seen, high speed brings a special factor into play, and that is comfort in curves. New single- purpose high-speed lines are laid out with due regard to comfort in curve5 and as far as possible large radius, canted curves are the norm. But what about existing lines? Where passenger and freight trains share a common route the question of curvature has to be very care fully considered.

For comfort on winding routes the tilting train is an answer. But, as we have seen, in Italy nausea became a problem and had to be addressed. More tilting trains will probably be used, but only where curves are very severe and the traffic warrants high speed over such routes. The additional complexity is expensive to install and maintain. Comfortable ride is another factor, determined by the train’s suspension. Air secondary springing is now well established. Air-bag manufacturing is well understood and air-springs are reliable. There will be some extension of air suspensions to very high-speed trains, in Germany in particular. But what about “active” suspensions?

So-called active systems were discussed in the chapter on tilting trains. Present vehicle suspensions may be described as “passive” — they react after something happens. Rail vehicle suspension in particular is a good example of the engineer’s art. The designer has to reconcile a number of conflicting requirements to cope with an unpredictable and changing series of demands. The primary aim is to cushion the passenger from the effects of irregularities in the track. To achieve this aim the designer uses primary and secondary suspensions, with various combinations of springs and dampers (a car’s primary springing is its rubber tires!).

The designer tries to produce a vehicle body that takes a level path through space and for the passengers to be unaware, as far as possible, of sharp disturbances of a relatively high frequency. These must be absorbed by the suspension. But there are also gentle, low-frequency disturbances. A slight dip in the track is a case in point. Here it is desirable for the coach body to follow the path of the bogie, or the body would tend to bounce on the secondary springs, which is uncomfortable. The aim of the vehicle designer must be to minimize the effect on the vehicle body of the “bumps” in the track, and at the same time minimize the displacement of the body relative to the bogie. Reducing the latter accentuates the former!

An active suspension has some external element to augment the effect of the secondary suspension. Much of the compromise of the passive suspension can be bypassed, yet, should the active element fail, the bogie must still have an acceptable ride. Electronic control can measure the parameters, and where there are conflicting demands filter out the information which is not relevant to particular conditions. With very high-speed travel, active suspension makes a lot of sense and here is an area where there is development potential for the future.

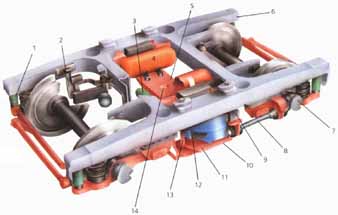

British Rail’s Experimental Air-spring Bogie:

1 Primary damper

2 Disc brake

3 Lateral damper

4 Air reservoir

5 Bolster

6 Bogie frame

7 Wheel-slide protection director

8 Traction rod

9 Leveling valve

10 Spring plank

11 Air-suspension indicator

12 Air-spring

13 Swing link

14 Center pivot

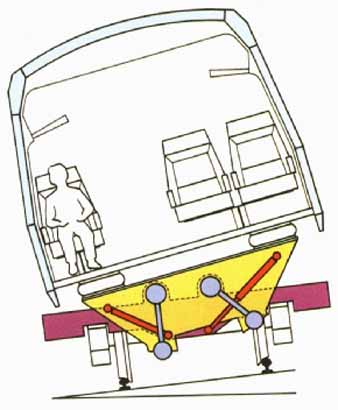

Car body tilt technology has been developed for increased

passenger comfort in curves. It has been found that the optimal compensation

for lateral acceleration is 80 per cent, which is achieved at tilting angles

up to a maximum of 8 degrees.

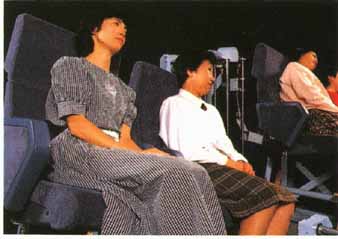

Increasingly high speeds on new- generation trains have

meant a greater concentration on passenger safety and comfort. At the Railway

Technical Research Institute in Japan, the effects of acceleration are

assessed in a test unit.

NEW TRANSPORT SYSTEMS

As long ago as 1966, the British Institution of Mechanical Engineers in London organized a conference with the title “Guided Land Transport”. It is interesting, 25 years on, to see what the conference identified as the major developments in trains leading up to the millennium.

(a) Pneumatic-tired trains of the Paris Metro type or variants.

(b) Monorails

(C) Guided air-cushion vehicles

(d) Magnetic suspension Maglev.

The first three have already been discussed, so it is appropriate here to have a brief look at Maglev because it is considered by some, particularly the Japanese, to be the replacement for conventional high-speed railways in the next century.

MAGLEV

The German high-speed system, known as Transrapid 06, was to have been a contender for one of the lines now operated as a Neubahnstrecke. The German Transport Ministry was not convinced that Maglev had demonstrated the level of safety necessary for a public transport system. Also, because it had to be carried on elevated concrete guideways, it was very far from environmentally friendly, so necessary in modern Germany.

The Japanese have a test track at Miyazaku and seemed to be having success. They have achieved a speed of 515 km/h (320 mph) while unmanned, and 407 km/h (253 mph) manned. Unfortunately in November 1991 a serious fire, apparently starting in the rubber-tired emergency wheels, damaged the vehicle badly. The Japanese are still pinning their faith on Maglev as a replacement for the Shinkansens when they pass their usefulness in the early part of the next century.

The low-speed installation, used as a people-mover between Birmingham International Airport and the adjacent British Rail station, has been operating well since 1984. There are two independent tracks, and normally one unmanned car operates on each under automatic control from a computer at the airport end. A third car is kept as a spare for maintenance and so on.

It is an eerie experience riding for the first time when the warning sounds and the doors close, to feel the vehicle rise some 15 mm then move off entirely automatically. There is a pronounced hum from the electronics. The tight first curve is negotiated slowly, the pitch of the electronic hum changes, and the vehicle accelerates to its cruising speed of about 40 km/h (25 mph). As the car approaches the airport terminal, the electronic hum changes down and the speed is reduced to negotiate the second sharp curve. The stop at the platform is smooth.

The car settles down on to the track and the doors open to allow the passengers out.

Other modern airports have not so far been attracted to Maglev, instead preferring the slightly less complex but well-developed Westinghouse (or similar) people- mover system used widely in the United States. This runs on a concrete guideway employing rubber tires and conventional dc motors. Installations in Britain include those at Gatwick and Stanstead airports.

This prototype linear motor car, which runs above the tracks

by magnetic levitation (MAGLEV), is undergoing trials at a test track

in Miyazaku. Japan.

THE FUTURE

To revert to the predictions of the 1966 conference, we can see that little has changed. Of the four non- conventional systems quoted, the use of rubber tires has had limited success and even the Paris Metro has only converted a few of its lines. Although the systems are capable of fast acceleration, the wear on the rubber tires has always been an on-going cost, and there is the problem of rubber being deposited on the guideways. Remote from French influence there has been little interest.

Monorails also enjoy very limited success. Those that have been successful are not true monorails but have a single beam with one carrying and two guide tracks, and a multiplicity of rubber tires. The same consideration of tire wear applies equally. Monorails are popular for pleasure parks where a scenic ride is needed, or they can be incorporated into the urban scene where there are space limitations.

Air-cushion vehicles have been tried and abandoned, for the moment anyway. Even the hovercraft has had a very limited application. Its main use has been for light transport over relatively difficult — mainly swampy or sandy—terrain.

Maglev is still in the development stage, particularly for high-speed transport. Permanent magnets have not been used for support as envisaged. So, as with air- cushion vehicles, power has to be expended to support the vehicles at the appropriate closely-controlled height above the guideways, using some form of computer control to maintain the vehicle within the very tight limits.

The main area for development would seem the extension of high-speed conventional railways. Already speeds in the 300-320 km/h (185-200 mph) range are safe and practical. Trains will be operating at those speeds very soon on new purpose-built lines in Europe and elsewhere. The use of microprocessors is already well- established, and they will have an even greater part to play in the next decade. Tilting trains have a place too to reduce journey times on existing routes where there are many curves, Radio control has not been mentioned so far. Radio control of locomotives has been employed for special purposes for many years. Radio-controlled signaling systems are now practical but security must be absolute, and inductive systems are more likely to be extended in the future. Radio communication between trains and ground stations is now part of the luxury train scene and will undoubtedly come into more general use in the near future. Radio communication between driver and ground control is now already being extended. It has been employed on the major railroads in the United States for a good many years.

Driverless trains, as we have seen, are practical, but the totally unmanned train is not so common. Because of the ever-present problem of vandalism, railway companies are reluctant to have no staff at all on trains. Totally safe operation under computer control is practical without train staff. But passengers need to feel secure, and the presence of somebody “in authority” on the trains lends some comfort, and may act as a deterrent to would-be vandals. Scanning of station platforms by video cameras is now common, and developments in visual communications will improve security.

ELECTRIFICATION

There is little doubt that we shall see much more electrification. It has always made sense to site power stations near to the sources of fuel, and these sites do not have to be near cities. Power distribution networks are well developed, and railways can and do tap into the distribution networks where they need the power.

We are used to high-voltage alternating current taken from overhead contact wires, and the normal voltage today is 25,000 volts. For the future there could be a case for reverting to direct current at around 12,000 volts. With the development of power electronic devices, it is no longer necessary to use direct current motors. The conversion from direct to variable-frequency alternating current is now practical and widely employed.

High-voltage direct current has attractions in a number of ways. Electromagnetic interference from the contact wires is largely eliminated, and losses in transmission are less. The electrical power link between England and France uses direct current because losses in an alternating current link would be untenable.

We have not touched urban transport, in which high technology will also play a major part in the future. This is a subject on its own. The major railway systems are all in intensely competitive situations today, and their success or otherwise is linked to the ability to make effective use of the new technology as it develops.

MAGLEV ENGINEERING’S OPTIMISM

To quote from the Institution of Mechanical Engineers conference again, the introduction to the subject of Magnetic Suspension contains the following:

Tracked transport by magnetic suspension is now a practical proposition for slow as well as highest speeds. Vehicles float with clearance of up to an inch on a magnetic field requiring no power expenditure, and hence without noise and the need for maintenance. Development is now at the man-carrying model stage, including propulsion-braking by simple dc linear motor that uses the track permanent field for excitation.

This (paper) summarizes nine years of development into what is considered to be their (massive permanent magnets’) largest and most important application, land transport, both guided and random-travel.

The objective is the magnetic suspension of simple raft-like vehicles. They float up to an inch above a track with a permanent field which also provides the medium for ideal weightless springing, shock-absorbing and simple linear propulsion All this work has reached the stage at which the basic problems appear to be solved, but much engineering remains to be done.

This all sounded very simple and attractive, but how much engineering really needed to be done is perhaps illustrated by the fact that today, 25 years after the above was written, there is one low-speed system operating in Britain at Birmingham Airport, one in Germany, and very high-speed systems still under development in Germany and Japan.

Next: Train/Rail Books & DVDs